Optoelectronic combination printing circuit board with optical interconnection direct coupling between chips

A printed circuit board and inter-optical technology, which is applied to the coupling of printed circuits and optical waveguides connected to non-printed electrical components, can solve the problems of difficult coupling and high alignment accuracy requirements, and achieve less optical components and easy coupling , Easy to connect and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

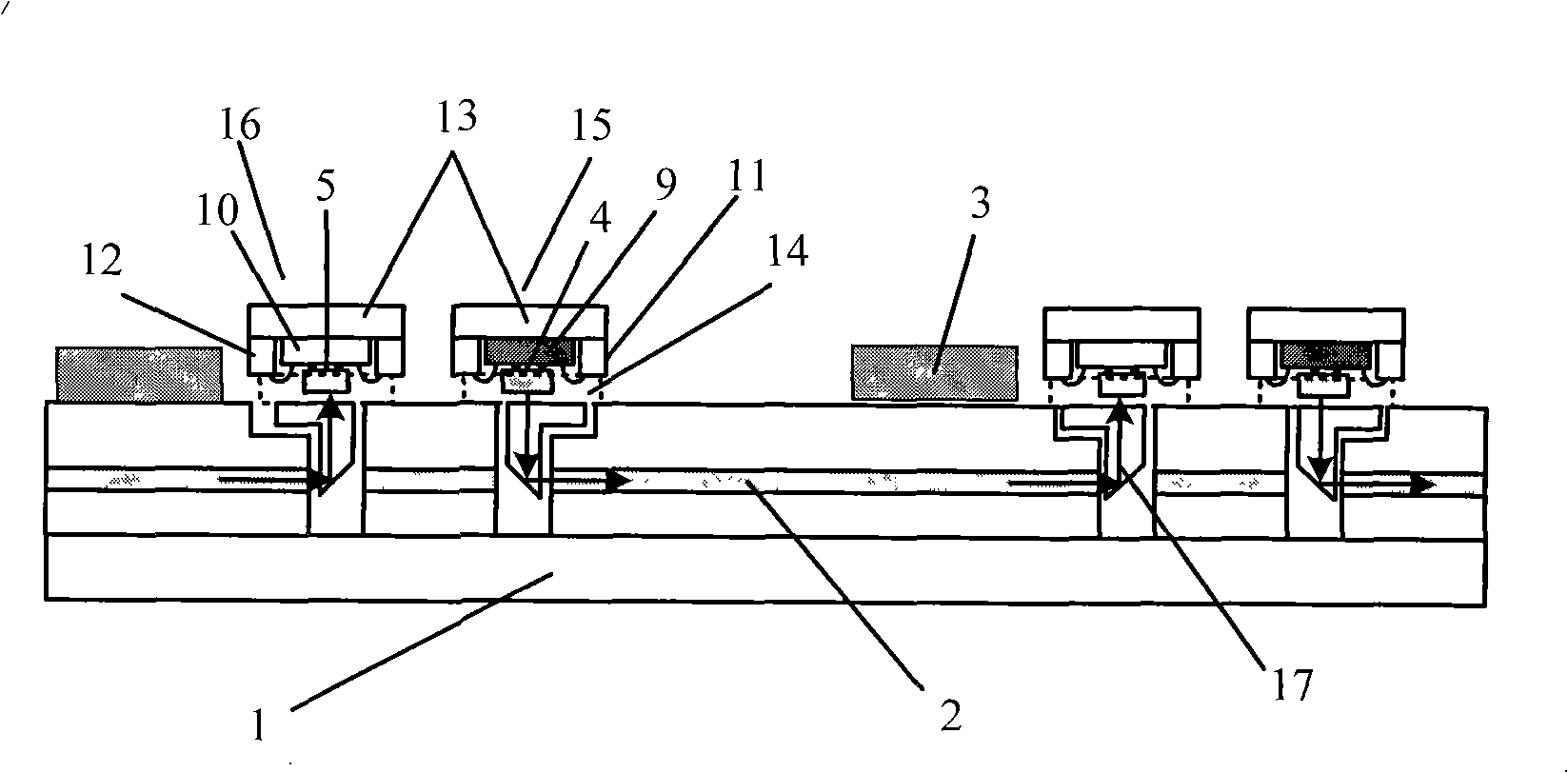

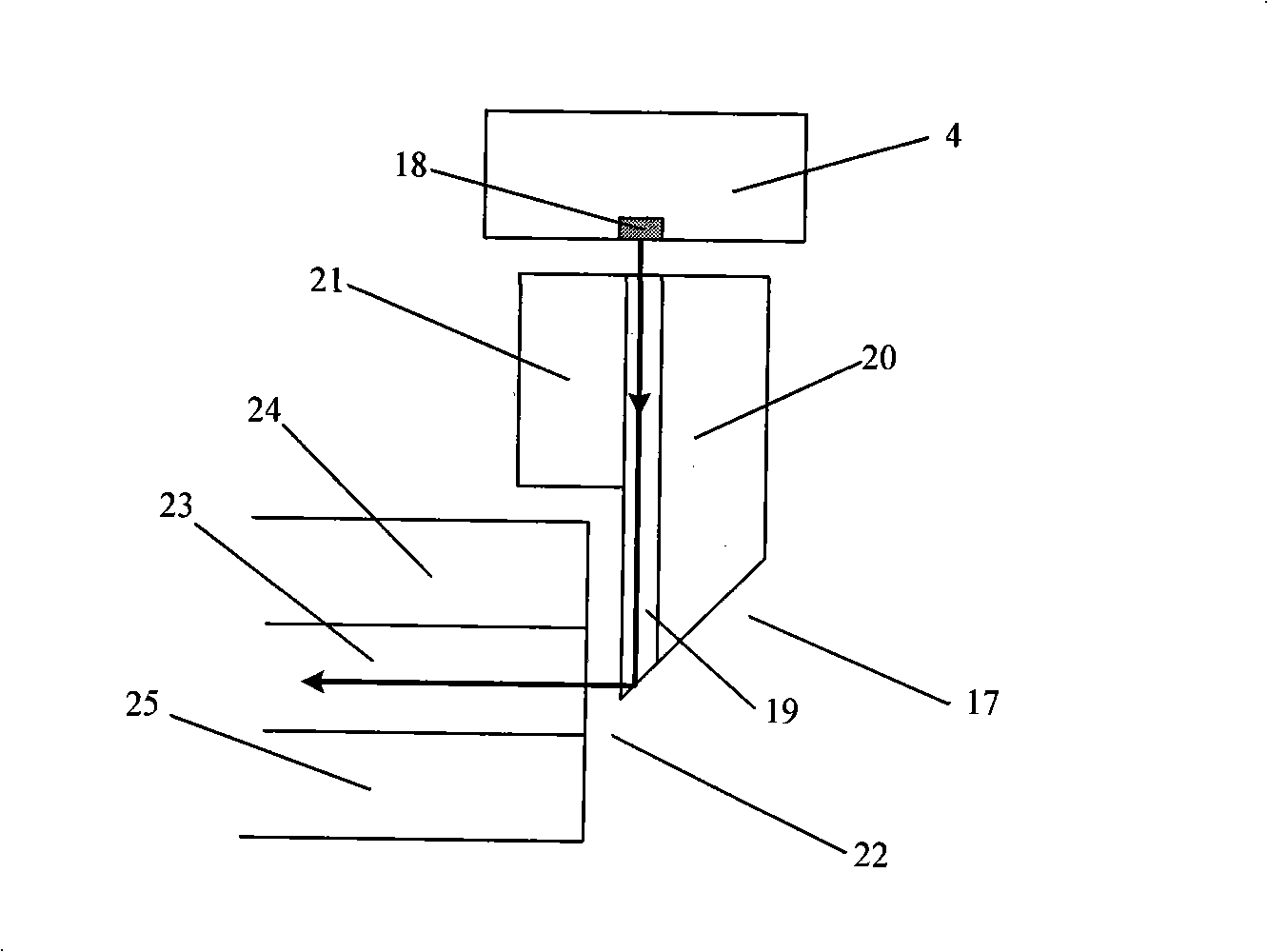

[0012] The structure of the embodiment of the present invention is as figure 2 shown. Marks in the figure: multilayer printed circuit board 1, optical waveguide layer 2, IC chip 3, VCSEL chip 4, PIN chip 5, drive circuit chip 9, transimpedance amplifier circuit chip 10, VCSEL interface circuit board 11, PIN interface circuit board 12. Copper heat sink socket 13, BGA lead pin socket 14, vertical cavity surface emitting laser device 15, PIN light receiving device 16, optical coupling connector 17.

[0013] Vertical cavity surface emitting laser device 15 is composed of VCSEL chip 4 , drive circuit chip 9 , VCSEL interface circuit board 11 bonded on copper heat sink base 13 , and BGA pin base 14 is welded on VCSEL interface circuit board 11 .

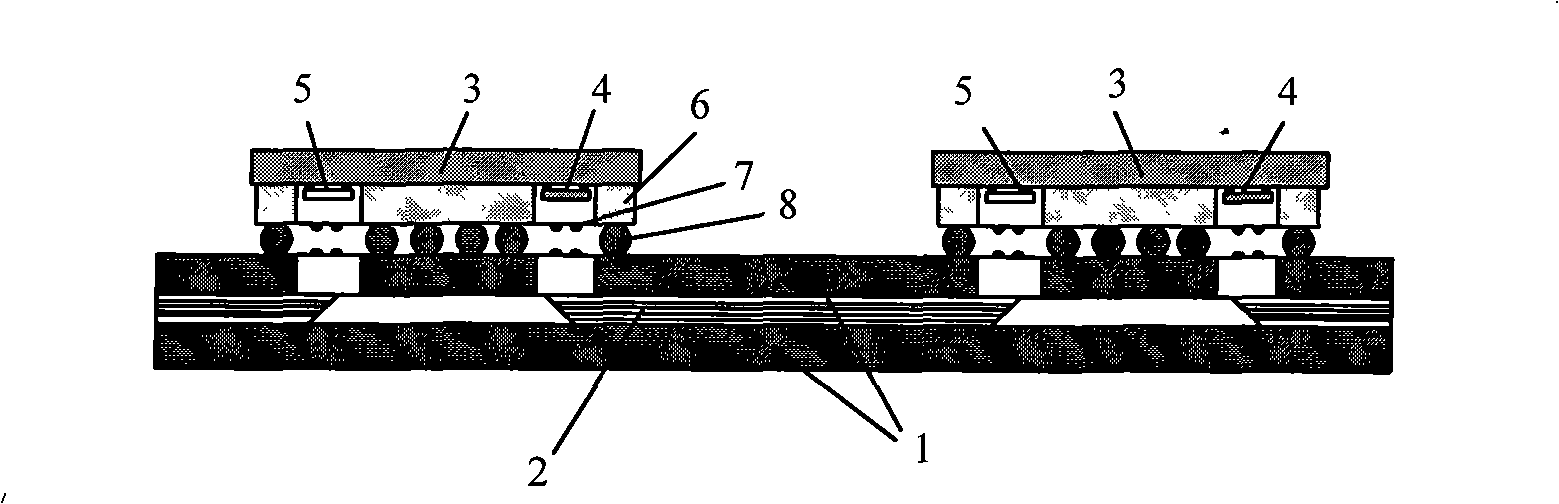

[0014] Each layer of the multilayer printed circuit board 1 is made of FR4 material, and the optical waveguide layer 2 is a polymer optical waveguide, which is embedded in the multilayer printed circuit board as an optical interconnectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com