Conductive polyelectrolyte polymerization liquid prescription stored in normal temperature steadily and use thereof

A conductive polymer and conductive polymer technology, applied in the field of polymer solution, can solve the problem that polymer solution cannot be stored stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

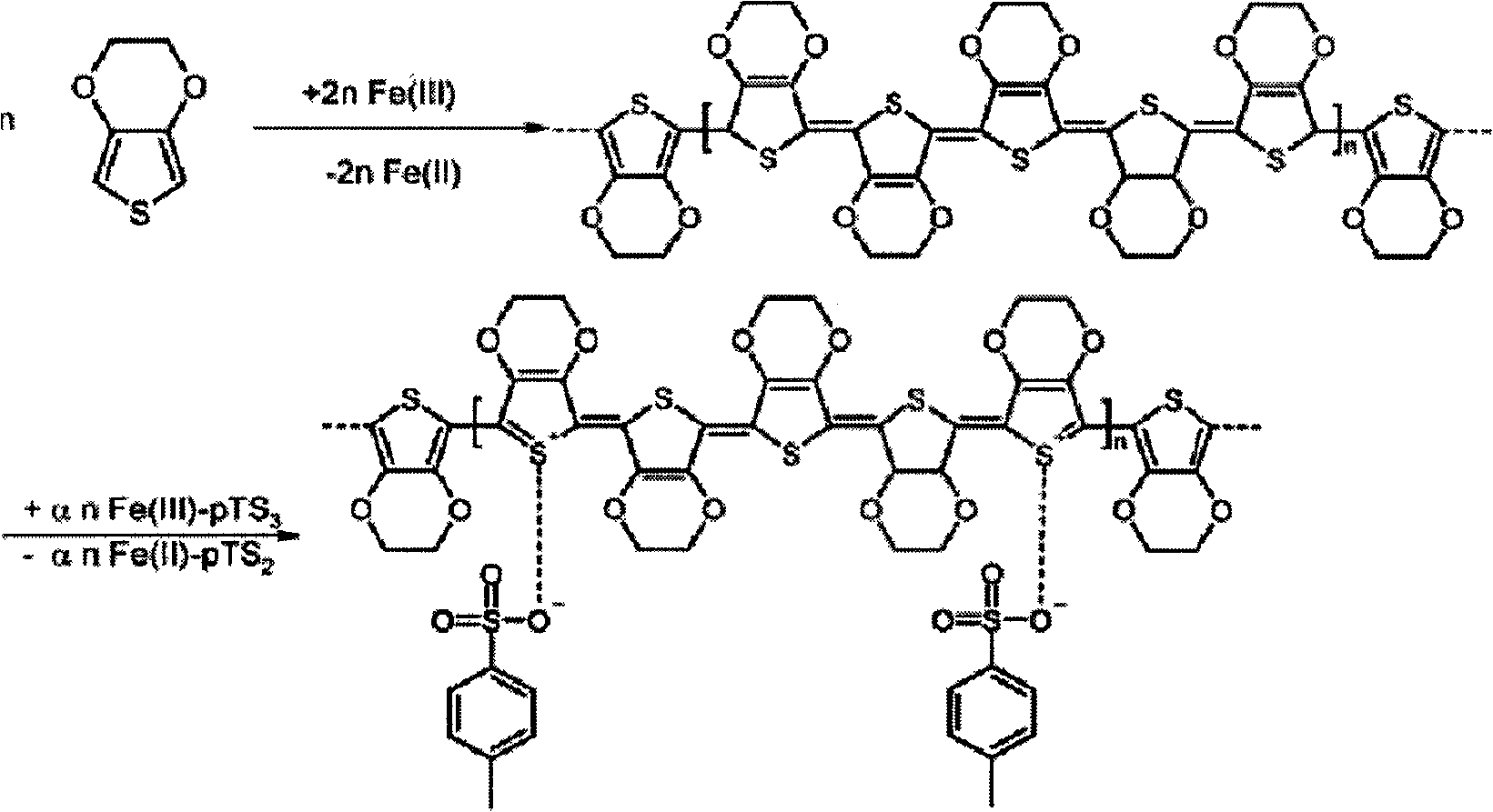

Method used

Image

Examples

Embodiment 1

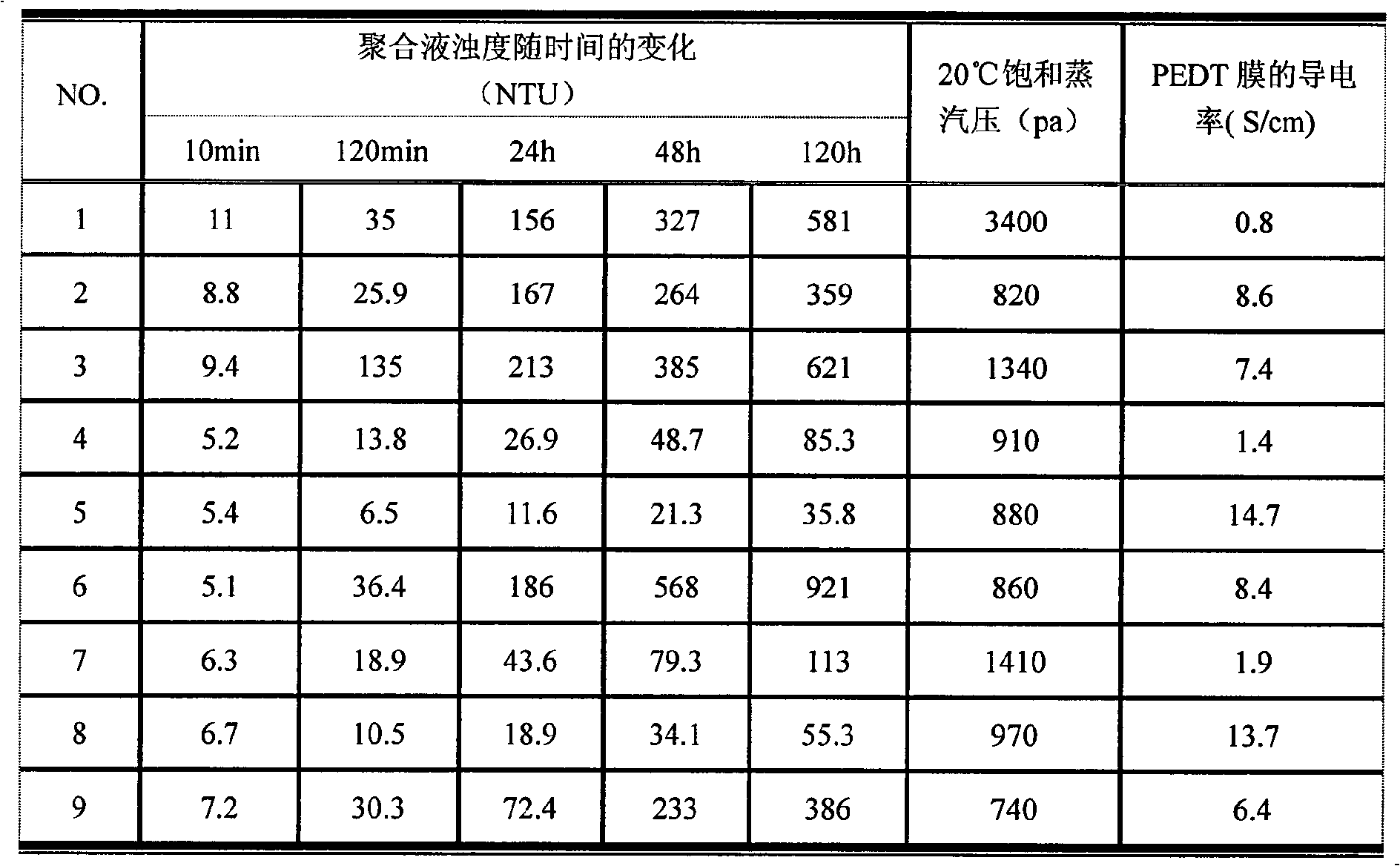

[0026] According to the proportions listed in Table 1 below, the listed oxidant such as iron (III) tosylate iron (III) methanesulfonate iron (III) is dissolved in a solvent such as ethanol or n-butanol to form an oxidant solution, and 3,4-ethylenedi Oxythiophene (EDT) monomer is prepared into a monomer solution with a solvent, and then the prepared oxidant solution and the monomer solution are mixed, and ultrasonic waves are used to vibrate the solution to fully mix the solution, and the mixed solution is measured at room temperature (20°C). The saturated vapor pressure of the solution is to make the saturated vapor pressure of the solution below 1000 Pa, and the change of the turbidity of the polymerization liquid over time is measured, and the results are shown in Table 2.

[0027] For each of the prepared polymerization solutions, the oxidative polymerization test was carried out according to the following steps: 1) Clean the 20×50mm glass slides with deionization and dry th...

Embodiment 2

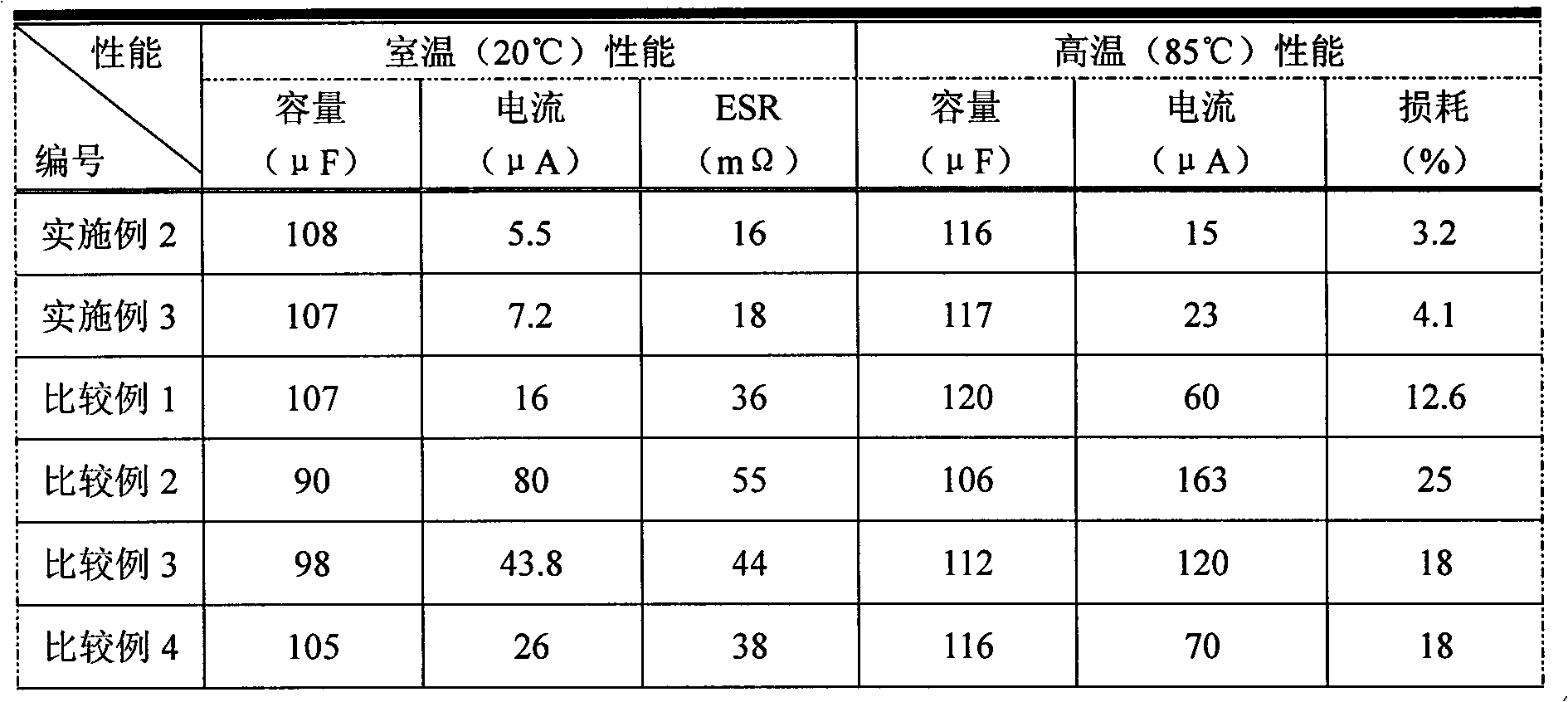

[0034] A sintered block of tantalum powder with a specific volume of 50,000 μF / g and a size of 4.3×3.1×1.1 (mm) was anodized in a 0.1wt% (weight percent) phosphoric acid solution, and the working voltage of the anodization was 33V. After anodizing, the agglomerate is boiled, washed and dried to form the capacitor core. Prepare the polymer solution with the 5# formula in Table 1, soak the above capacitor core in the polymer solution for 5min-10min, then place the tantalum core soaked in the polymer solution at room temperature to dry for about 10min, and then place it at 40℃- React in an oven at 60°C for 15 minutes, and then heat-treat at 120°C for 10 minutes. Then wash the core with deionized water for 30 minutes, repair the anode tantalum core in 0.1wt% p-toluenesulfonic acid aqueous solution for 30 minutes, then rinse and dry in deionized water, and then immerse and dry as described 5 times , heat treatment and supplementary forming process.

[0035] Next, graphite silver ...

Embodiment 3

[0037] Prepare the polymer solution with the No. 8# formula listed in Table 1, then dip the capacitor core with the specification as in Example 2 into the polymer solution, and make a capacitor in the same way, and its characteristics are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com