Method for processing hybrid Rumex acetosa

A technology of hybrid sorrel and ultrafiltrate, which is applied in the direction of organic fertilizer, animal feed, animal feed, etc., can solve the problems of less application of deep processing in the later stage, resistance to application promotion, single form of deep processing in the later stage, etc., and achieve the effect of increasing economic added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, the processing of hybrid sorrel

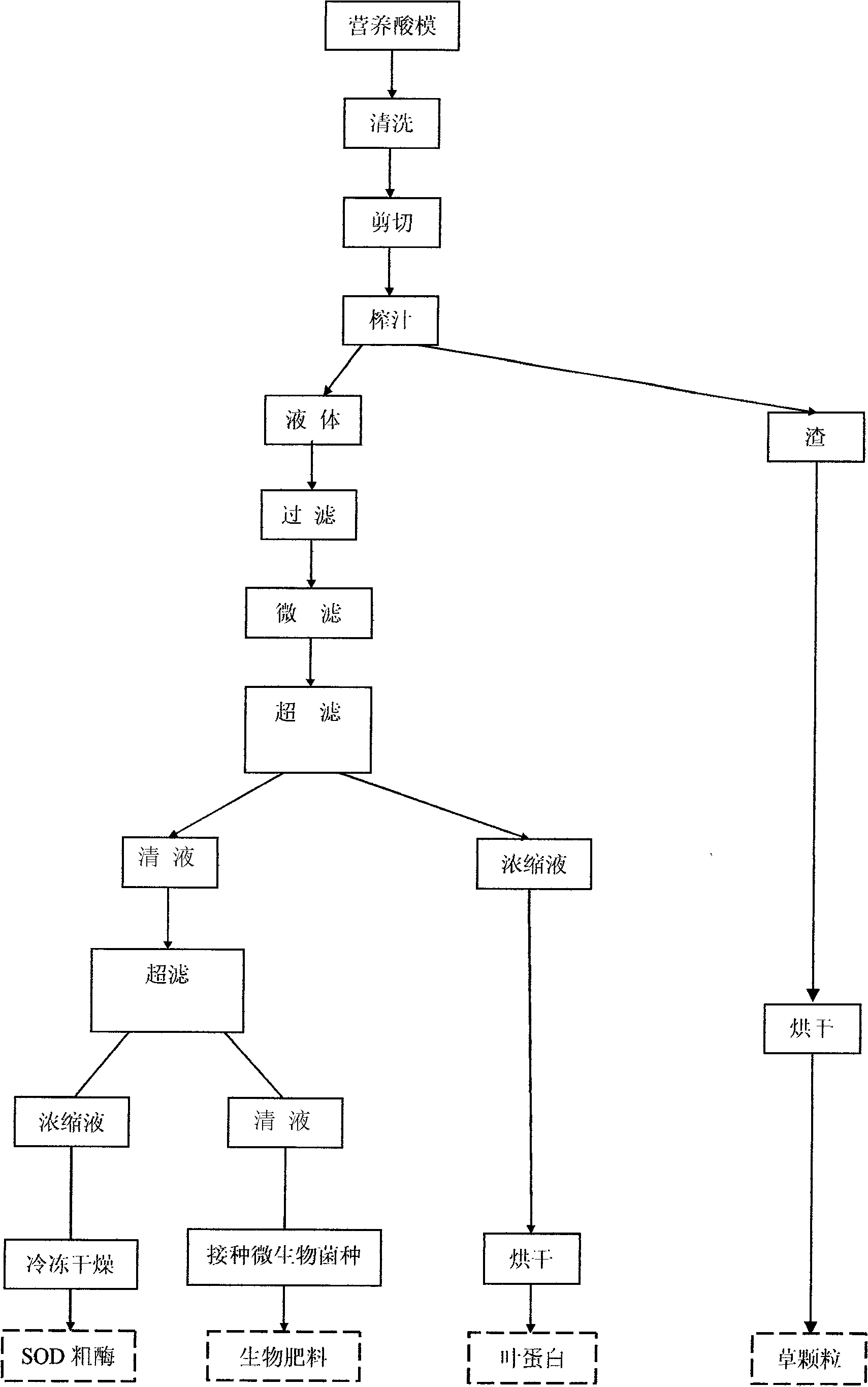

[0015] The processing flow of hybrid sorrel is as follows: figure 1 shown

[0016] 1. Extraction of grass particles

[0017] 1 ton of fresh hybrid sorrel body was cleaned and sent to a shearing machine to cut into shreds, and then squeezed with a juicer to obtain 750L of juice. After the sorrel juice is squeezed, the remaining residue is dried at 80°C to obtain 0.1 ton of green powdery grass granules, with a protein content of about 28.56%, a fiber content of 14.26%, and a moisture content of 8.42%.

[0018] 2. Extraction of leaf protein

[0019] The 750L juice obtained in the above steps is microfiltered with a polypropylene thermal spray fiber membrane, the filtration accuracy is 5um, and the filtration area is 0.5m 2 , Pressure 0.08MPa filter, remove fine particles such as coarse fibers and so on. Then use a hollow fiber ultrafiltration membrane with a molecular weight cut-off of 60,000 for ultrafiltration. Membra...

Embodiment 2

[0025] Other steps are the same as in Example 1, except that step two uses a flat ultrafiltration membrane with a molecular weight cut-off of 60,000. Membrane material: polysulfone, membrane area: 0.15m 2 , length: 30cm, width: 15cm, height: 5cm. Ultrafiltration at 0.17MPa for 45 minutes to obtain 670L of ultrafiltrate and 80L of ultrafiltration concentrate. Obtain 0.18kg of granular leaf protein product, and its protein content is 39.5%.

Embodiment 3

[0027] Other steps are the same as in Example 1, except that step 2 uses a roll-type ultrafiltration membrane with a molecular weight cut-off of 60,000. Membrane material: polyacrylonitrile, membrane area: lateral area: 3200cm 2 , cross-sectional area: 2.4cm 2 . Ultrafiltration at 0.17MPa for 48 minutes to obtain 660L of ultrafiltrate and 90L of ultrafiltration concentrate. Obtain 0.18kg of granular leaf protein product, and its protein content is 39.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com