Novel technique for preparing 4-formyl amino antipyrine

A technology of aminoantipyrine and antipyrine, applied in the direction of organic chemistry, can solve the problems of incomplete separation of feed liquid and colloid, high cost of production raw materials, and affecting the quality of finished products, and achieve large-scale continuous automatic operation , easy to extract and stratify, and reduce the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention does not change the original production conditions of each reaction step (nitrosation, reduction, hydrolysis, neutralization, acylation).

[0021] Take 800ml of 4-aminoantipyrine hydrolyzate (the mass content of 4-aminoantipyrine is about 12%), cool down to 55°C, add chloroform to extract according to a certain volume ratio of hydrolyzate and chloroform, and the extraction temperature is 45-55°C. ℃. During the extraction process, the chloroform layer containing the colloid in the lower layer is separated, the chloroform is recovered by distillation, and the chloroform is recycled. Take the hydrolyzed solution in the upper layer according to the original process, neutralize and acylate to obtain 4-formylaminoantipyrine.

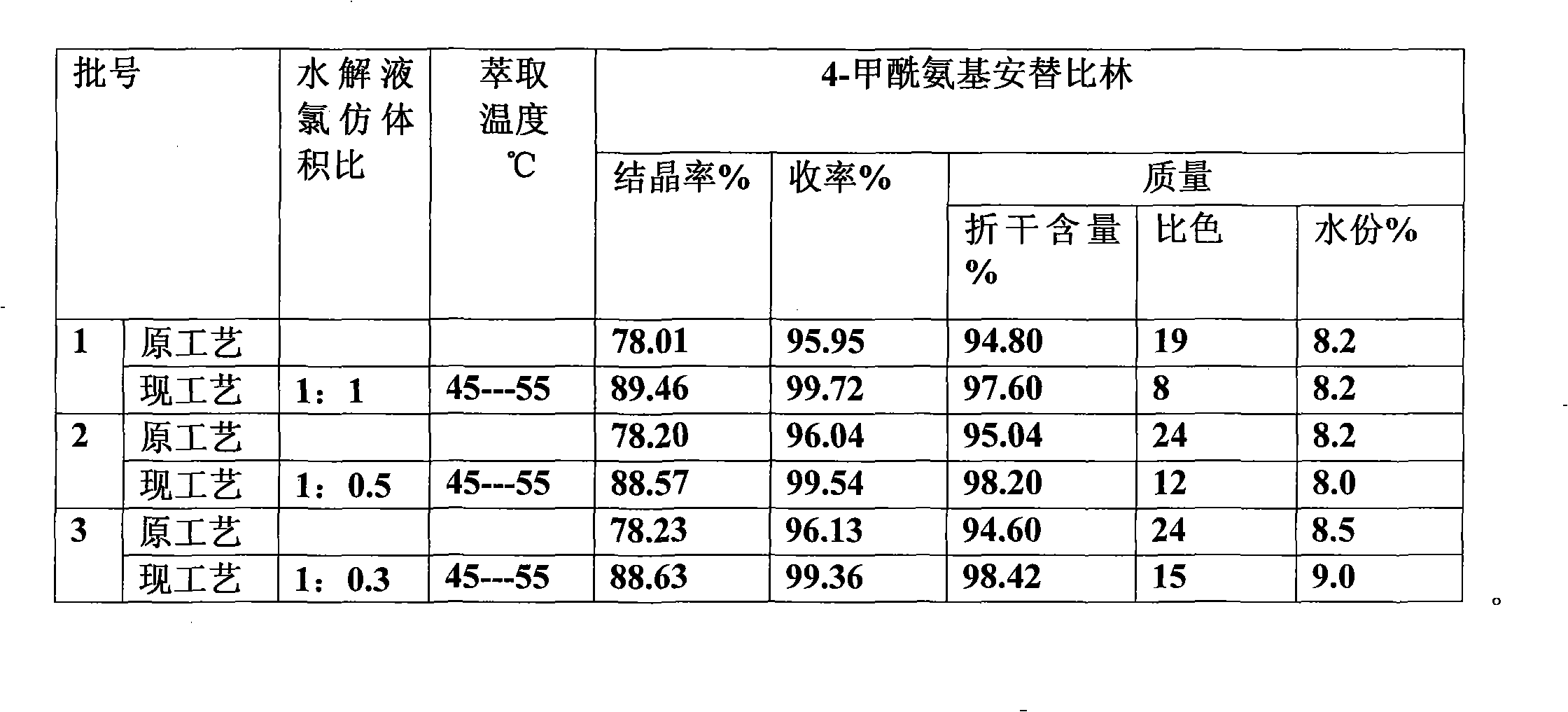

[0022] Add chloroform extraction with hydrolyzate and chloroform certain volume ratio (1: 1, 1: 0.5, 1: 0.3) below, compare with the original process, the result is as follows:

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com