Production process for high purity porcine blood albumin and uses thereof

A production process and technology for albumin, applied in the directions of serum albumin, albumin peptides, animal/human proteins, etc., can solve the problems of no inclusion of albumin and serum, complicated purification process, long cycle, etc., and achieve low cost and preparation. The effect of simple process and less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

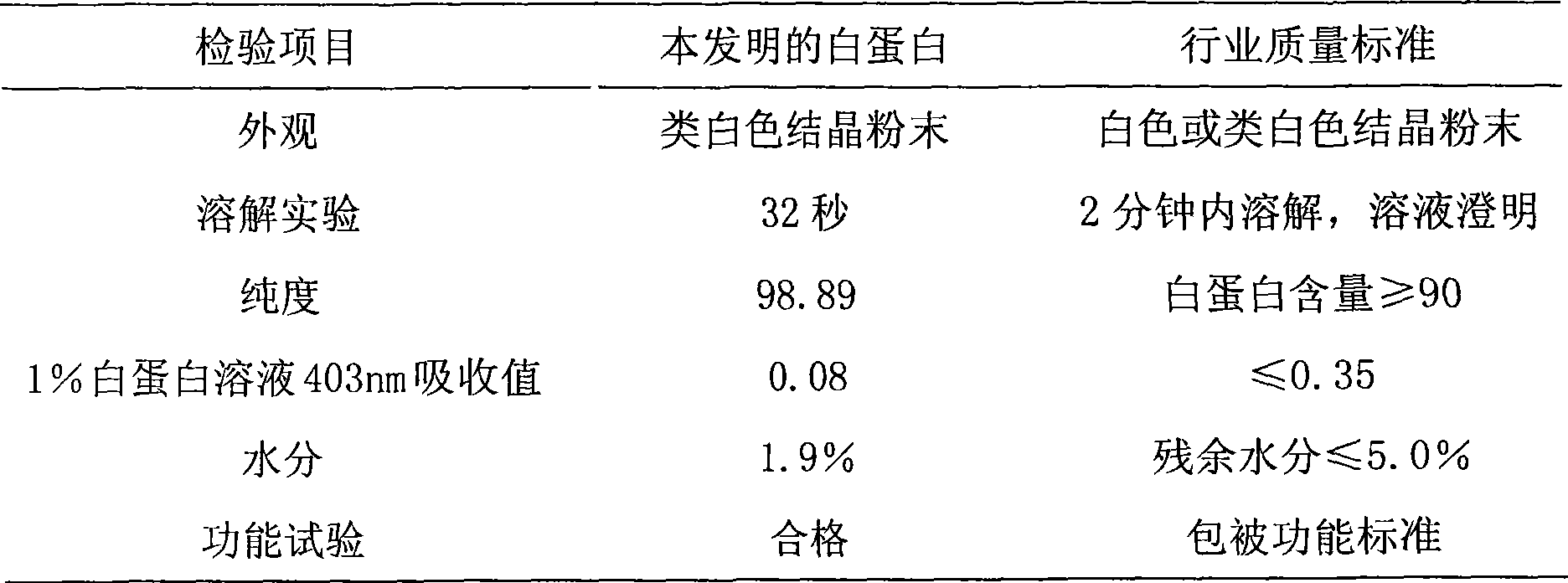

Examples

Embodiment 1

[0037] Take 56,000ml of fresh pig blood from pigs that have been strictly quarantined and free from infectious diseases, add it to 6,220ml of 3.8% sodium citrate and 0.9% sodium chloride solution, and let the blood stand in a 3°C freezer for 10 hours. The erythrocytes are stratified, and the plasma is absorbed by the siphon method, and the lower layer of blood cells is used separately; the above-mentioned separated plasma is placed in a centrifugal system with a refrigeration device, and the temperature of the refrigeration system is set at 5°C. Turn on the centrifuge and centrifuge at a speed of 5000 rpm minutes, centrifuged for 50 minutes, and collected plasma. The plasma is then filtered with a 0.22μm filter to obtain about 28,000ml of purified plasma;

[0038] Put the refined plasma into the interlayer reaction tank, and heat the interlayer tank to 70°C; take 93.1g of sodium octanoate and 252g of sodium chloride, add them to 28000ml of purified water and dissolve them, and...

Embodiment 2

[0040] Take 40,000ml of fresh pig blood from pigs without infectious diseases after strict quarantine, add it to 4450ml solution containing 3.8% sodium citrate and 0.9% sodium chloride, and put the blood in a cold storage at 8°C for 8 hours, then the plasma and The erythrocytes are stratified, and the plasma is absorbed by the siphon method, and the blood cells in the lower layer are used separately; the above-mentioned separated plasma is placed in a centrifugal system with a refrigeration device, and the temperature of the refrigeration system is set at 8°C. Turn on the centrifuge and centrifuge at a speed of 5000 rpm minutes, centrifuged for 45 minutes, and collected plasma. The plasma is then filtered with a 0.22μm filter to obtain about 20,000ml of purified plasma;

[0041] Put the refined plasma into the interlayer reaction tank, and heat the interlayer tank to 70°C; take 66.5g of sodium octanoate and 180g of sodium chloride, and add them to 20,000ml of purified water to...

Embodiment 3

[0043] Take 50,000ml of fresh pig blood from pigs without infectious diseases after strict quarantine, add it to 5560ml solution containing 3.8% sodium citrate and 0.9% sodium chloride, and put the blood in a cold storage at 5°C for 8 hours. The erythrocytes are stratified, and the plasma is absorbed by the siphon method, and the lower layer of blood cells is used separately; the above-mentioned separated plasma is placed in a centrifugal system with a refrigeration device, and the temperature of the refrigeration system is set to 10°C. Turn on the centrifuge and centrifuge at a speed of 3000 rpm minutes, centrifuged for 60 minutes, and collected plasma. The plasma is then filtered with a 0.22μm filter to obtain about 25,000ml of purified plasma;

[0044] Put the refined plasma into the interlayer reaction tank, and heat the interlayer tank to 70°C; take 83.2g of sodium octanoate and 225.0g of sodium chloride, add them to 25000ml of purified water and dissolve them, and add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com