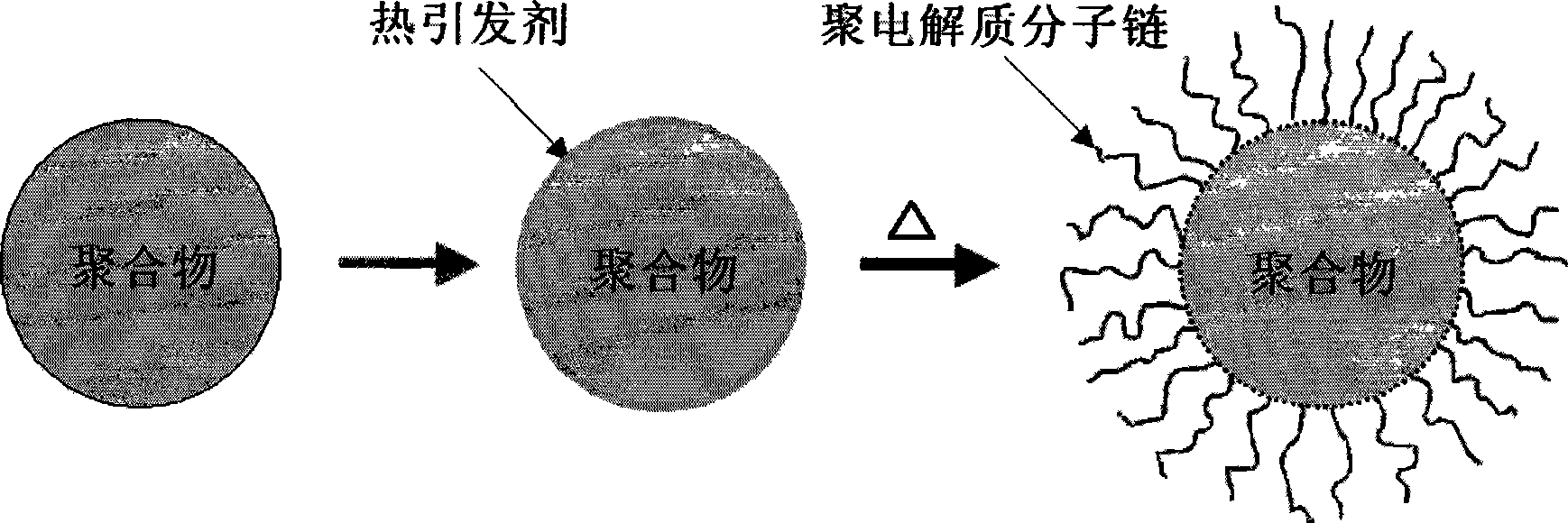

Preparation method of spherical polyelectrolyte brush and use thereof

A polyelectrolyte brush, spherical technology, applied in the field of medical diagnosis, can solve the problems of unsuitable monomer, unfavorable industrial production, expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

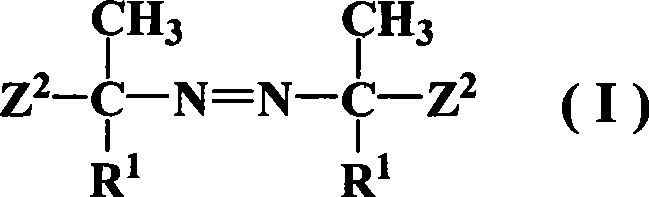

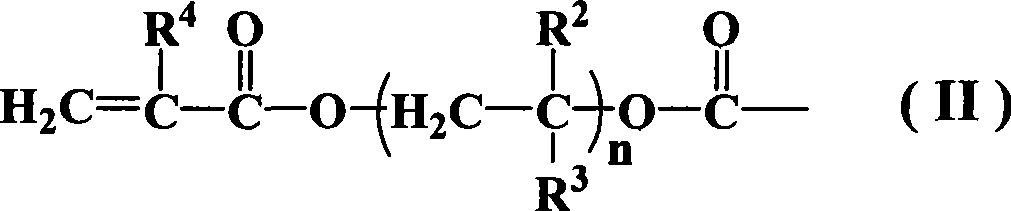

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Preparation of Nanopolymer Microemulsion Balls by Redox Emulsion Polymerization

[0016] Put 150ml of deionized water, 0.4g of sodium dodecylsulfonate, and 4.0g of potassium persulfate into a 500ml three-neck flask. After fully dissolving, 9.8 g of styrene was added. Pump nitrogen 3 to 5 times, and control the speed at 300 rpm. After the temperature rose to 40°C, 1.5g of sodium bisulfite was dissolved in 50ml of deionized water, and quickly dropped into the flask. During the reaction process, the temperature and rotation speed were kept constant, and the polymerization reaction ended after 6 hours.

Embodiment 2

[0017] Example 2 Preparation of Nanopolymer Microemulsion Balls by Redox Emulsion Polymerization

[0018] Put 150ml of deionized water, 0.6g of sodium dodecylsulfonate, and 6.0g of potassium persulfate into a 500ml three-neck flask. After fully dissolving, 9.4 g of methyl methacrylate was added. Pump nitrogen 3 to 5 times, and control the speed at 400 rpm. After the temperature rose to 35°C, 2.3g of sodium bisulfite was dissolved in 50ml of deionized water, and quickly dropped into the flask. During the reaction process, the temperature and rotation speed were kept constant, and the polymerization reaction ended after 4 hours.

Embodiment 3

[0019] Example 3 Preparation of polymer microemulsion spheres coated with thermal initiator

[0020] Take Example 1. At the end of the redox emulsion polymerization, slowly add 0.5 g of the thermal initiator dropwise into the reaction system, and the dropping speed is controlled at 8 drops / min. After the dropwise addition, the reaction was continued for 8 hours. The obtained emulsion was put into a dialysis bag and then dialyzed in deionized water, and the deionized water was replaced 5 to 8 times until the ionic strength of the deionized water no longer changed. The particle size of the polymer emulsion particles changed little before and after coating, and the average particle size was 57.4nm measured by dynamic light scattering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com