Metal and non-metal pyrogenation separation method on waste printed plate board

A printed circuit board and separation method technology, applied in the direction of solid waste removal, electronic waste recycling, recycling technology, etc., can solve the problem of failure to meet resource recovery and environmental protection, effective recycling of usable materials, and reduction of metal recycling issues such as efficiency and purity, to achieve the effect of facilitating sorting and recycling, reducing energy consumption, and overcoming metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

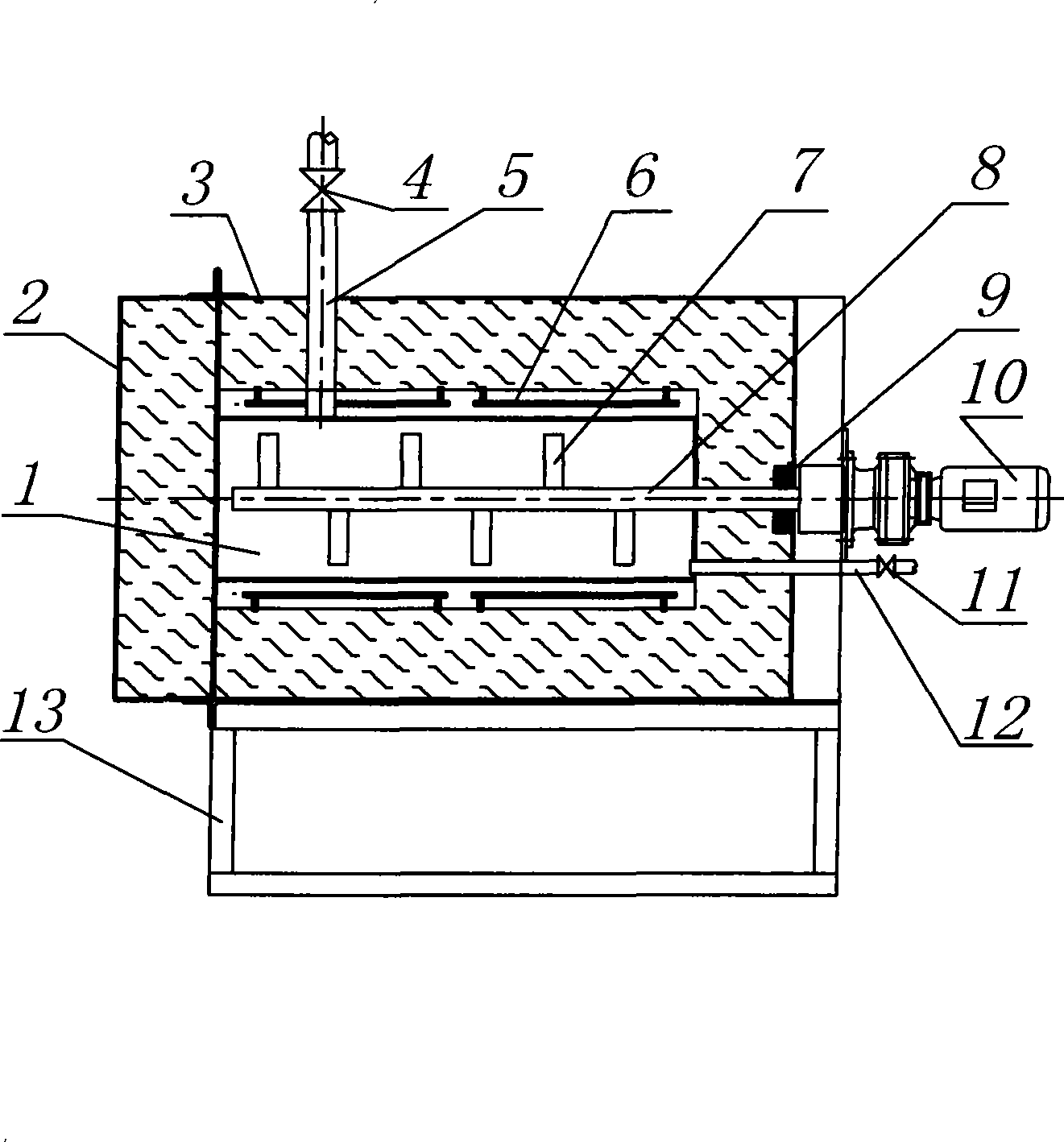

Image

Examples

Embodiment 1

[0024] Put the waste printed circuit boards into the furnace of the pyrolysis device, close the furnace door and let nitrogen gas flow for 4 minutes, the nitrogen flow rate is 40 liters / min, so as to completely discharge the air in the furnace to form an anaerobic environment; The heating rate of min is to heat the material in the furnace. After the temperature rises to 700°C, keep the temperature for 25 minutes and stop the furnace. During the heating process of the material, the inlet valve is closed, and the opening of the outlet valve is adjusted. Keep 2~3mmH in the furnace 2 Slight positive pressure of O and irregular stirring of the materials; the pyrolysis products are discharged from the pyrolysis device, and the liquid and gas products are separated by the container after heat exchange with tap water at 15°C as the cooling medium. be collected.

[0025] After testing: the recovery rate of metals can reach more than 96%, and the recovery rate of available non-metals c...

Embodiment 2

[0027] Put the waste printed circuit boards into the furnace of the pyrolysis device, close the furnace door and let nitrogen gas flow for 3 minutes, the nitrogen flow rate is 50 liters per minute, so as to completely discharge the air in the furnace to form an anaerobic environment; The heating rate of min is to heat the material in the furnace. After the temperature rises to 650°C, keep the temperature for 20 minutes and stop the furnace. During the heating process of the material, the inlet valve is closed, and the opening of the outlet valve is adjusted. Keep 1.8~2.8mmH in the furnace 2Slight positive pressure of O and irregular stirring of the material; the pyrolysis product is discharged from the pyrolysis device, and the liquid and gas products are separated by the container after heat exchange with tap water at 20°C as the cooling medium. be collected.

[0028] After testing: the recovery rate of metals can reach more than 96%, and the recovery rate of non-metals can ...

Embodiment 3

[0030] Put the waste printed circuit boards into the furnace of the pyrolysis device, close the furnace door and let nitrogen gas flow for 5 minutes, the nitrogen flow rate is 30 liters per minute, so as to completely discharge the air in the furnace to form an anaerobic environment; The heating rate of min is to heat the material in the furnace. After the temperature rises to 600°C, keep the temperature for 30 minutes and stop the furnace. During the heating process of the material, the inlet valve is closed, and the opening of the outlet valve is adjusted. Keep 2.5-3.8mmH in the furnace 2 Slight positive pressure of O and irregular stirring of the materials; the pyrolysis products are discharged from the pyrolysis device, and the liquid and gas products are separated by the container after heat exchange with tap water at 25°C as the cooling medium. be collected.

[0031] After testing: the recovery rate of metals can reach more than 96%, and the recovery rate of available n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com