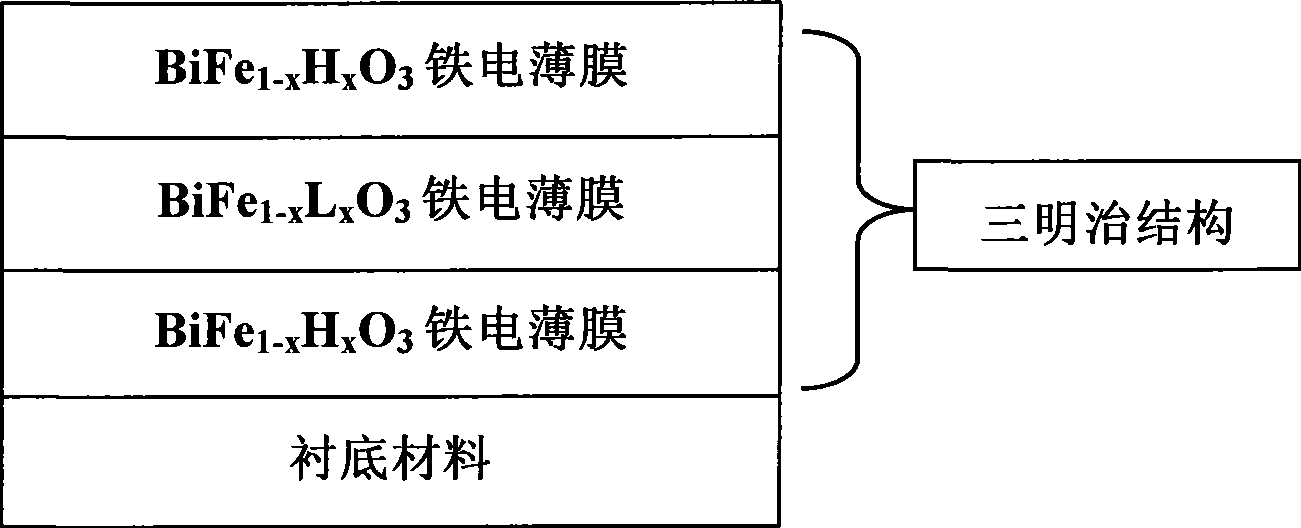

BiFeO3 based sandwich construction thin-film for ferro-electric memory and preparation thereof

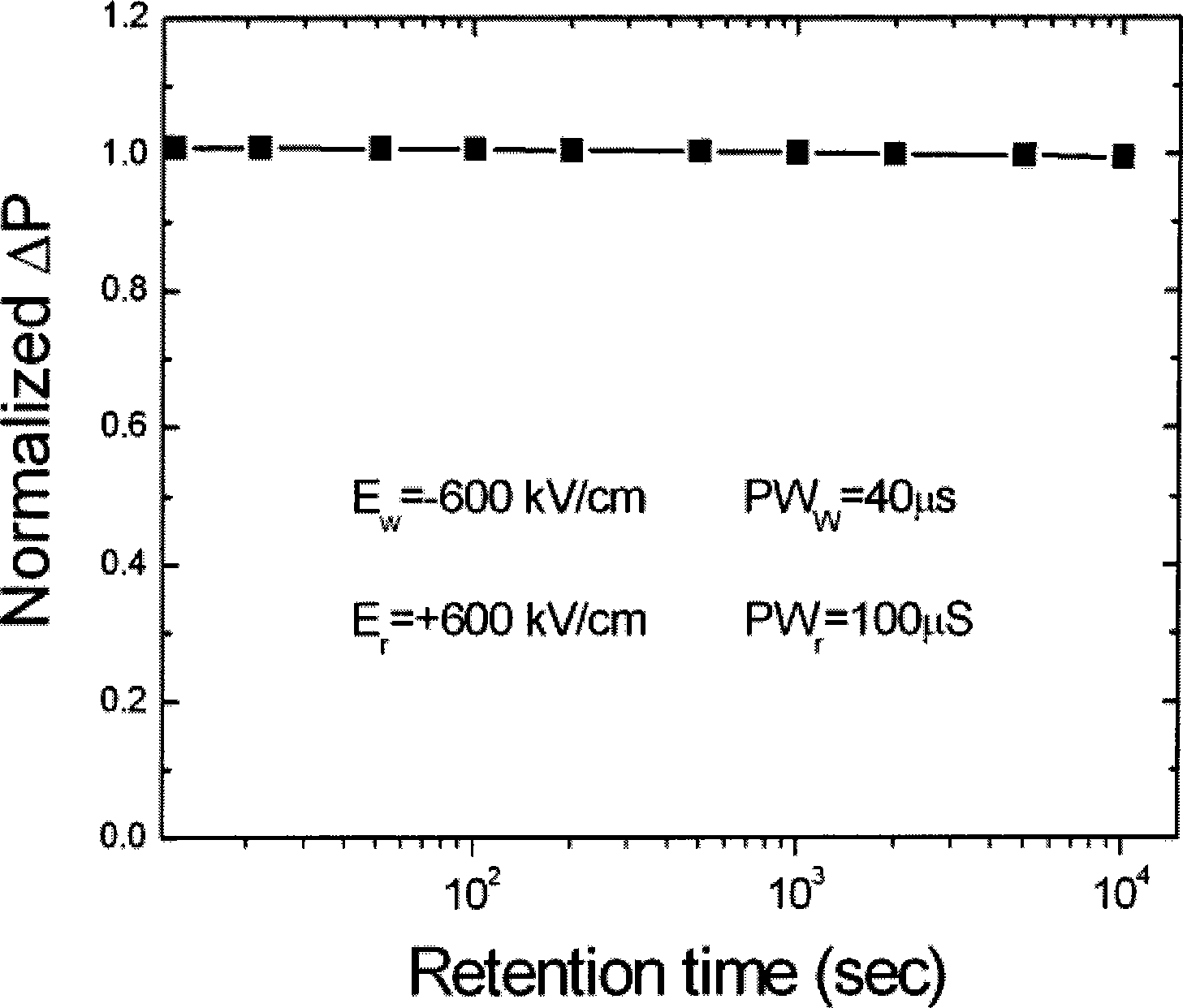

A ferroelectric memory, based sandwich technology, applied in the field of BiFeO3-based sandwich structure film and its preparation, can solve the problems of high leakage current, high charge retention, high residual polarization and the like of ferroelectric thin film, and achieves the reduction of leakage current, Improved charge retention, effect of large remanent polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The BiFeO used in the ferroelectric memory of the present embodiment 3 -Based sandwich structure film, the upper and lower surface materials are BiFe 0.98 Ti 0.02 o 3 Thin film, the middle layer material is BiFe 0.98 Zn 0.02 o 3 .

[0023] The preparation method of above-mentioned sandwich structure film is:

[0024] (1) Weigh bismuth nitrate, ferric nitrate and tetrabutyl titanate with a molar ratio of 1.02:0.98:0.02 respectively, dissolve bismuth nitrate and ferric nitrate with 40ml of ethylene glycol, configure solution A, take tetrabutyl titanate Equal volume of acetylacetone to form complex solution B, after stirring solutions A and B for 40 minutes, mix and prepare BiFe with a concentration of 0.10mol / L 0.98 Ti 0.02 o 3 Precursor solution: Weigh bismuth nitrate, iron nitrate and zinc nitrate with a molar ratio of 1.02:0.98:0.02 and dissolve them in 40ml of ethylene glycol, and prepare BiFe with a concentration of 0.10mol / L according to conventional method...

Embodiment 2

[0028] The BiFeO used in the ferroelectric memory of the present embodiment 3 -Based sandwich structure film, the upper and lower surface materials are BiFe 0.98 Zr 0.02 o 3 Thin film, the middle layer material is BiFe 0.97 La 0.03 o 3 .

[0029] The preparation method of above-mentioned sandwich structure film is:

[0030] (1) Weigh bismuth nitrate, iron nitrate and zirconium isopropoxide with a molar ratio of 1.02:0.98:0.02 respectively, dissolve bismuth nitrate and iron nitrate with 40ml ethylene glycol, and prepare BiFe with a concentration of 0.10mol / L 0.98 Zr 0.02 o 3 Precursor solution: Weigh bismuth nitrate, ferric nitrate and lanthanum nitrate with a molar ratio of 1.02:0.97:0.03 and dissolve them in 40ml of ethylene glycol, and prepare BiFe with a concentration of 0.10mol / L according to conventional methods. 0.97 La 0.03 o 3 Precursor solution;

[0031] (2) Using the same method as in Example 1, the precursor solution is deposited sequentially, the precur...

Embodiment 3

[0033] The BiFeO used in the ferroelectric memory of the present embodiment3 -Based sandwich structure film, the upper and lower surface materials are BiFe 0.99 Ta 0.01 o 3 Thin film, the middle layer material is BiFe 0.95 mn 0.05 o 3 .

[0034] The preparation method of above-mentioned sandwich structure film is:

[0035] (1) Weigh bismuth nitrate, ferric nitrate and tantalum ethoxide with a molar ratio of 1.02:0.99:0.01 respectively, dissolve bismuth nitrate and ferric nitrate with 40ml of ethylene glycol, configure solution A, and take acetylacetone equal to the volume of tantalum ethoxide To form complex solution B, stir solutions A and B for 40 minutes respectively, then mix and prepare BiFe with a concentration of 0.05mol / L 0.99 Ta 0.01 o 3 Precursor solution: Weigh bismuth nitrate, ferric nitrate and manganese nitrate with a molar ratio of 1.02:0.95:0.05 and dissolve them in 40ml of ethylene glycol to prepare 0.15mol / L BiFe 0.95 mn 0.05 o 3 Thin film precurso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com