Method for preparing molybdate nanocrystalline

A technology of molybdate and nanocrystals, which is applied in the field of preparation of molybdate nanostructures, can solve the problems of expensive precursor method, difficult process control, and low yield, and achieve low synthesis process cost, convenient operation, and simple experimental process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

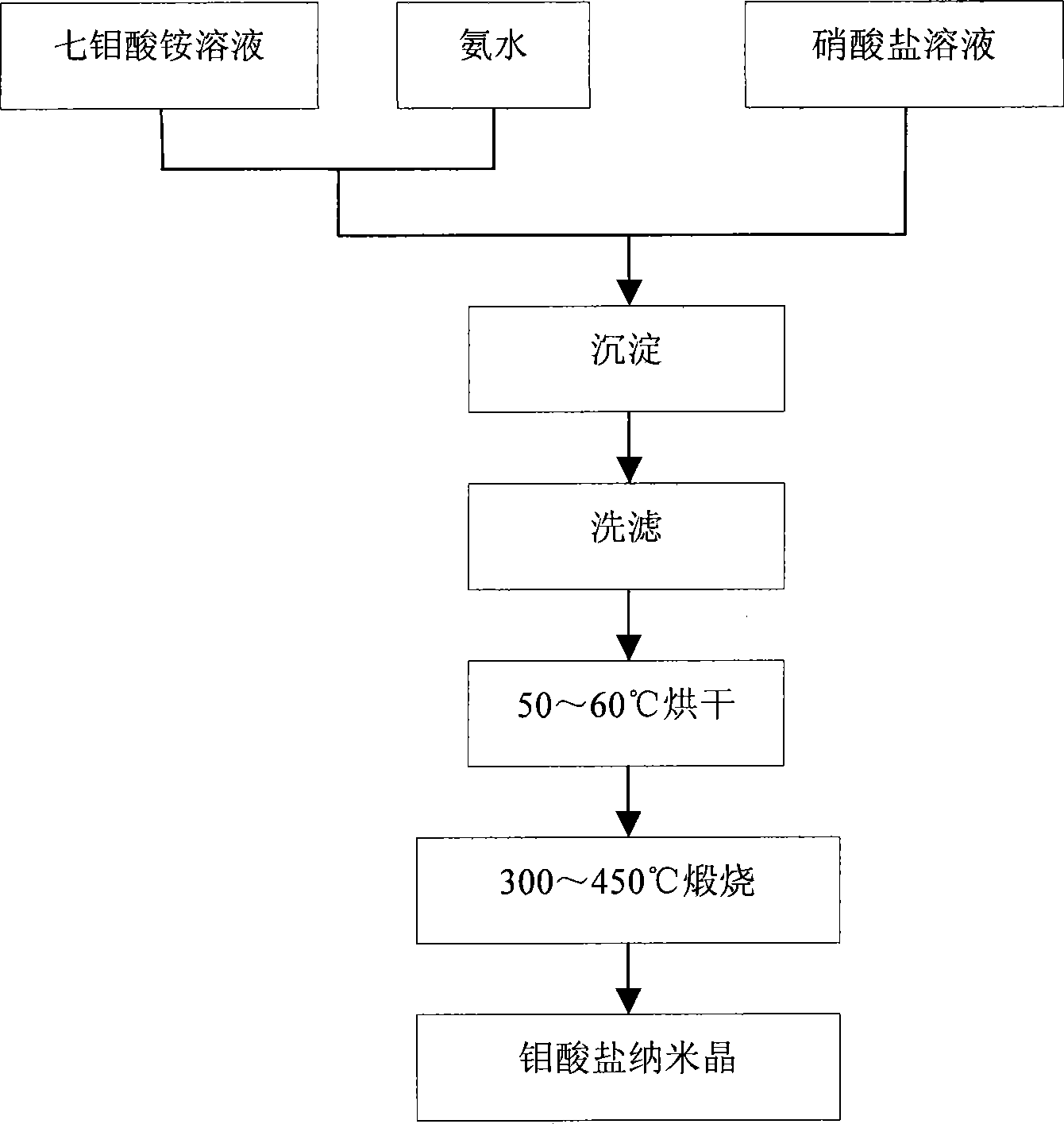

Method used

Image

Examples

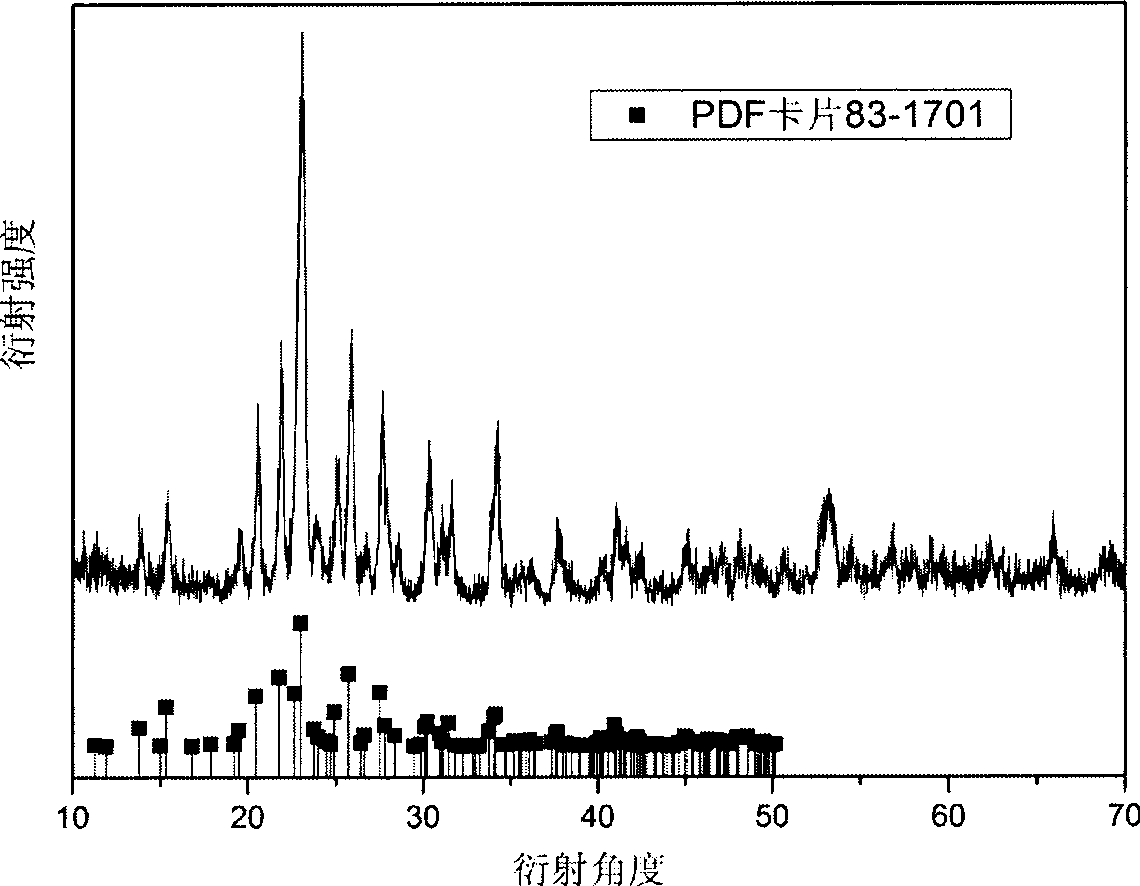

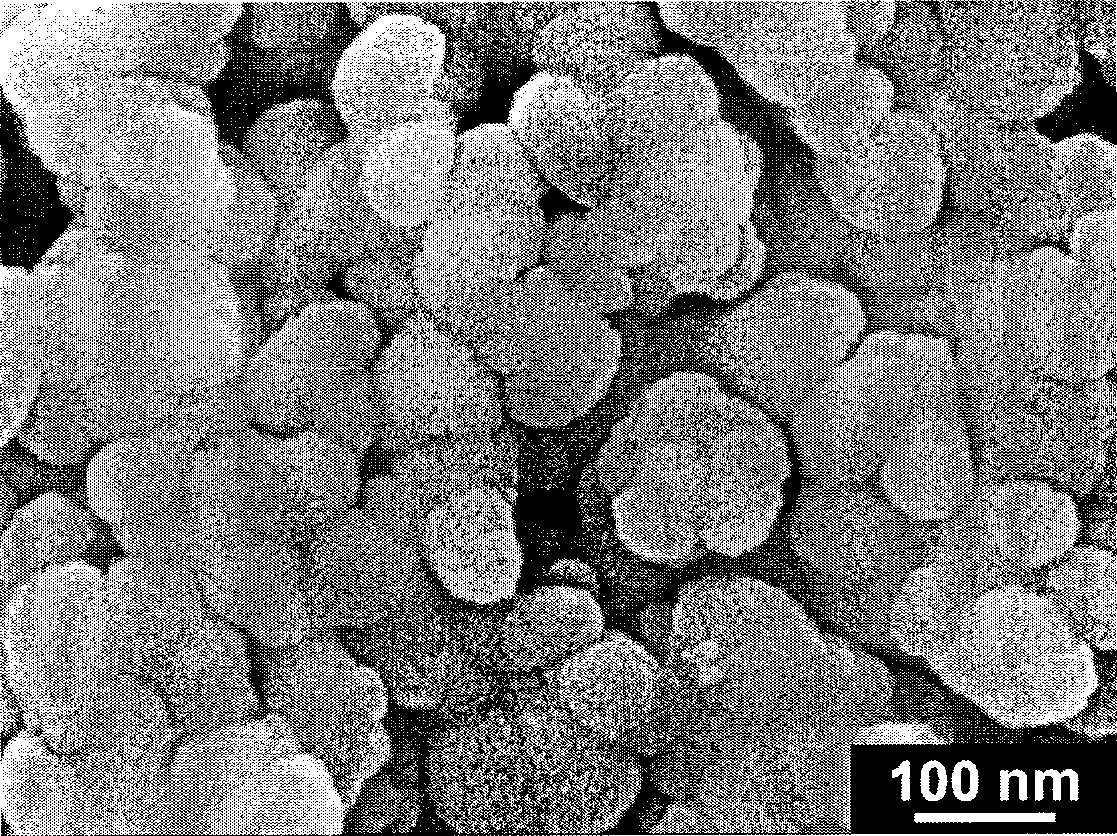

Embodiment 1

[0023] Dissolve 2.47g of ammonium heptamolybdate in 200mL of deionized water, stir to form a transparent solution of 0.01 mol / L; dilute concentrated ammonia water to a concentration of 2 mol / L, take 8.5mL and add dropwise to the ammonium heptamolybdate solution , to obtain a mixed solution of ammonium heptamolybdate and ammonia water; 3.77g of ferric nitrate was dissolved in 100mL of deionized water, and dissolved rapidly after stirring to form a transparent solution of 0.093 mol / liter. Under magnetic stirring at 400-1000 rpm, ferric nitrate solution is added dropwise to the mixed solution of ammonium heptamolybdate and ammonia water, and the solution immediately produces precipitation, which increases continuously as the reaction progresses. Continue to stir for 2 hours after the ferric nitrate solution is completely dripped in. The obtained precipitates are washed and filtered with deionized water and absolute ethanol for 3 times respectively, and then dried at 50°C for 5 hou...

Embodiment 2

[0025] Dissolve 2.47g of ammonium heptamolybdate in 200mL of deionized water, stir to form a transparent solution of 0.01 mol / L; dilute concentrated ammonia water to a concentration of 2 mol / L, take 8.5mL and add dropwise to the ammonium heptamolybdate solution , to obtain a mixed solution of ammonium heptamolybdate and ammonia; 3.26mL mass percent of 50% manganese nitrate solution was diluted to 100mL with deionized water to form a 0.14 mol / liter transparent solution. Add manganese nitrate solution dropwise to the mixed solution of ammonium heptamolybdate and ammonia water under magnetic stirring at 400-1000 rev / min, and precipitates will appear in the solution immediately, and the precipitates will continue to increase as the reaction progresses. Continue to stir for 2 hours after the manganese nitrate solution is completely dripped in. The obtained precipitates are washed and filtered with deionized water and absolute ethanol for 3 times respectively, and then dried at 50°C ...

Embodiment 3

[0027] Dissolve 2.47g of ammonium heptamolybdate in 200mL of deionized water, stir to form a transparent solution of 0.01 mol / L; dilute concentrated ammonia water to a concentration of 2 mol / L, take 8.5mL and add dropwise to the ammonium heptamolybdate solution , to obtain a mixed solution of ammonium heptamolybdate and ammonia water; 4.07g of cobalt nitrate was dissolved in 100mL of deionized water, and dissolved rapidly after stirring to form a transparent solution of 0.14 mol / liter. Under magnetic stirring at a speed of 400-1000 rpm, add cobalt nitrate solution dropwise to the mixed solution of ammonium heptamolybdate and ammonia water, and precipitates will appear in the solution immediately, and the precipitates will continue to increase as the reaction progresses. Continue to stir for 2 hours after the cobalt nitrate solution is completely dropped in, and the obtained precipitates are washed and filtered with deionized water and absolute ethanol for 3 times respectively, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com