Method for quickly producing removalbe partial denture bracket

A rapid and denture technology, applied in medical science, dental prosthesis, dentistry, etc., can solve the problems of irreversible deformation, irregularity, and scrapping of parts, so as to reduce the formation of internal stress in the workpiece, reduce manufacturing costs, and shorten the manufacturing cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Selective Laser Melting Rapid Fabrication of Stainless Steel Removable Partial Denture Frames

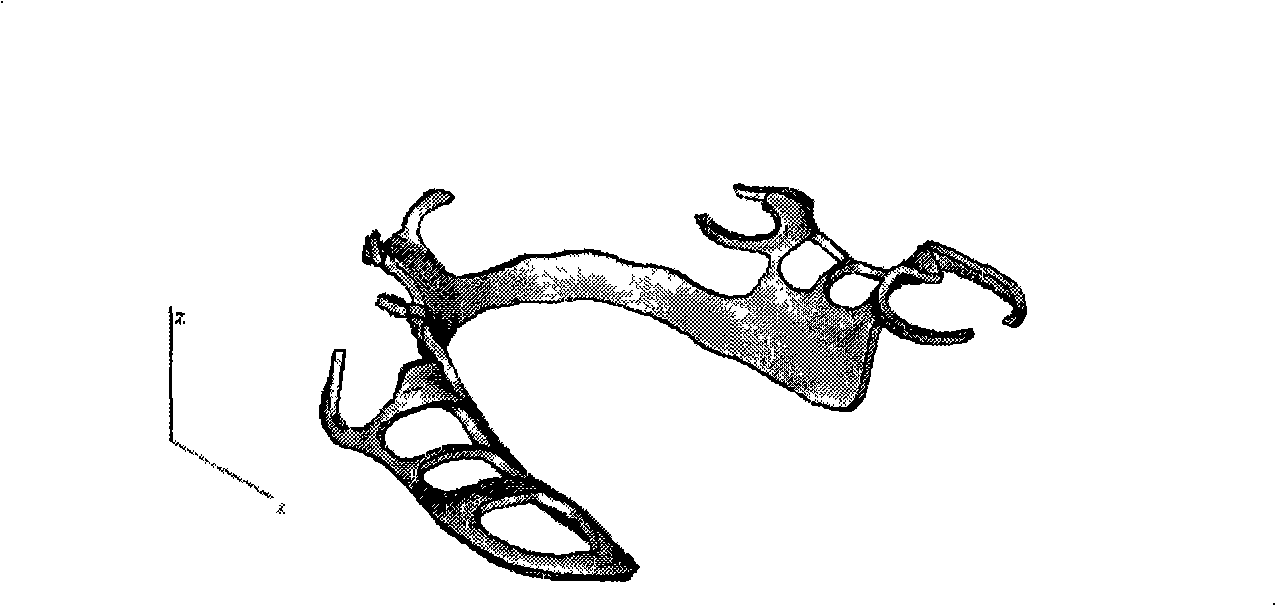

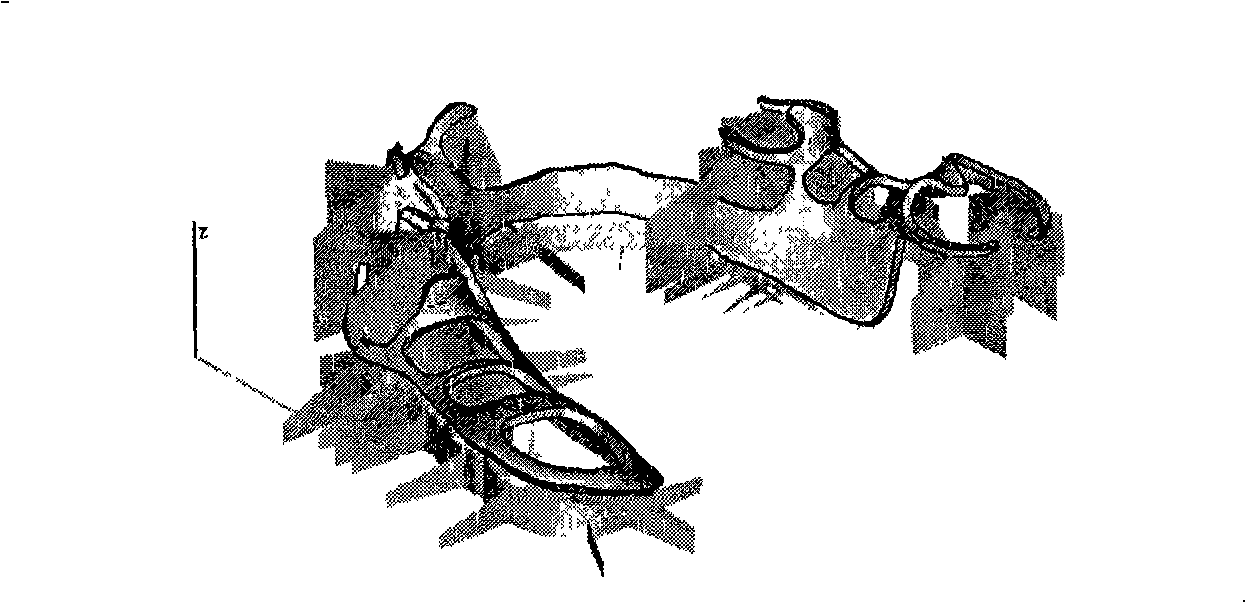

[0027] refer to figure 1 and figure 2 graphics. Will figure 2 The 3D part model with saw-toothed thin-wall support added is saved as an STL format file, and layered slicing software is used for layered discretization to generate laser processing CNC instructions. A continuous YAG laser was used to make denture brackets with stainless steel alloy powder with a particle size of <45 μm. A 25 mm thick stainless steel plate was used as the substrate. The thickness of the powder was 60 μm, the speed of powder spreading was 3.0 m / min, and the height of each drop of the forming cylinder was 20 μm.

[0028] The laser processing parameters of the first layer are: laser power 150W, scanning speed 50mm / s, overlap amount 0.01mm. The laser processing parameters of the subsequent layer are: laser power 130W, scanning speed 250mm / s, overlapping amount 0.04mm.

[0029] After...

Embodiment 2

[0030] Example 2: Rapid Fabrication of Cobalt-Chromium Alloy Removable Partial Denture Brackets by Selective Laser Melting

[0031] refer to figure 1 and figure 2 graphics. Will figure 2The 3D part model with saw-toothed thin-wall support added is saved as an STL format file, and layered slicing software is used for layered discretization to generate laser processing CNC instructions. A continuous semiconductor pumped solid-state laser is selected, and the material for making the denture bracket is cobalt-chromium alloy powder with a particle size of <40 μm. The stainless steel plate with a thickness of 30 mm is used as the substrate, and the thickness of the powder is 40 μm. The drop height is 20 μm, and the production process is protected by high-purity argon.

[0032] The laser processing parameters of the first layer are: laser power 150W, scanning speed 150mm / s, overlap amount 0.02mm. The laser processing parameters of the subsequent layer are: laser power 150W, sc...

Embodiment 3

[0034] Example 3: Rapid Manufacturing of Titanium Alloy Removable Partial Denture Brackets by Selective Laser Melting

[0035] refer to figure 1 and figure 2 graphics. Will figure 2 The 3D part model with saw-toothed thin-wall support added is saved as an STL format file, and layered slicing software is used for layered discretization to generate laser processing CNC instructions. The continuous Yb fiber laser is selected, and the material for making the denture bracket is Ti-6Al-4V alloy powder with a particle size of less than 20 μm. The titanium plate with a thickness of 40 mm is used as the substrate, and the thickness of the powder is 20 μm. The drop height is 20 μm, and the production process is protected by high-purity argon.

[0036] The laser processing parameters of the first layer are: laser power 160W, scanning speed 150mm / s, overlap amount 0.03mm. The laser processing parameters of the subsequent layer are: laser power 140W, scanning speed 800mm / s, overlapp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com