Free radical deep oxidization reactor

A deep oxidation and reactor technology, applied in the field of water treatment and circular economy, can solve the problems of low ozone dissolution efficiency, insufficient reaction, affecting the transmittance of ultraviolet light, etc. The effect of gas emission and improving dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a deep oxidation reactor for free radicals, which can operate continuously, and can be used as an advanced treatment reactor for slightly polluted water or a pretreatment reactor for high-concentration organic polluted water, so as to ensure the secondary treatment of waste water. After the effluent passes through the reaction system, it can meet the requirements of reuse, so as to solve the water pollution problem caused by the shortage of water resources and refractory organic matter to a certain extent; as a pretreatment reactor, it can be used in wastewater containing high concentrations of organic pollutants The pretreatment stage is to improve water quality, increase its biodegradability, and provide guarantee for subsequent biochemical reactions.

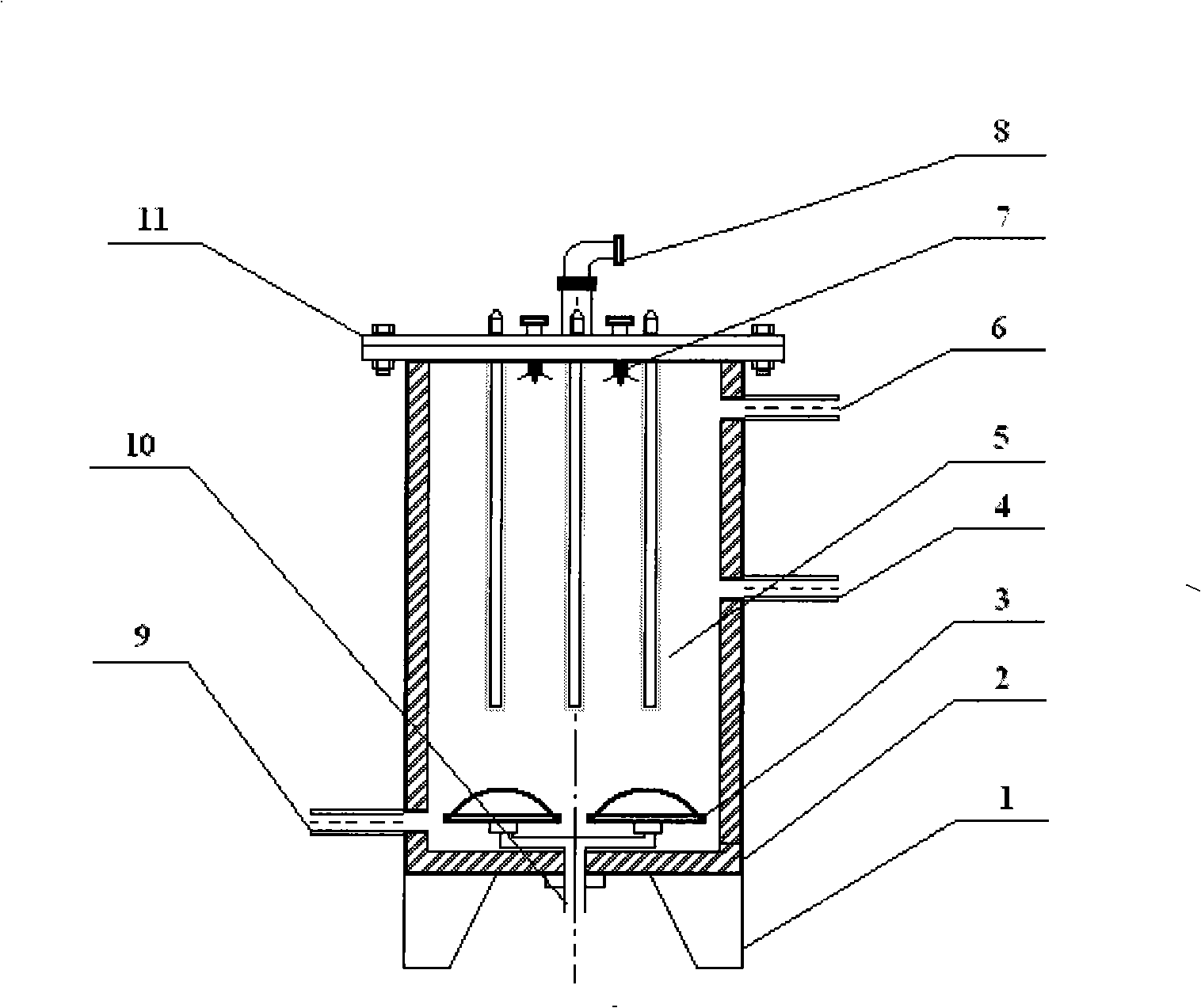

[0024] The reactor structure is as figure 1 As shown, it specifically includes: a reactor body 2, an ultraviolet lamp 5 and an aeration device 3; wherein, the reactor body 2 is a closed contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com