Corrosion-resistant single-body hydraulic supporter and its processing method

A technology of a single hydraulic prop and a processing method, which is applied in the direction of props/supports, earthwork drilling and mining, and devices for coating liquid on the surface, which can solve the problem of affecting the comprehensive mechanical properties of the matrix, unfavorable physical and mental health of operators, and affecting the sealing performance of products and other issues, to achieve strong market competitiveness and promotion and application prospects, superior sealing performance, superior flame retardant and antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

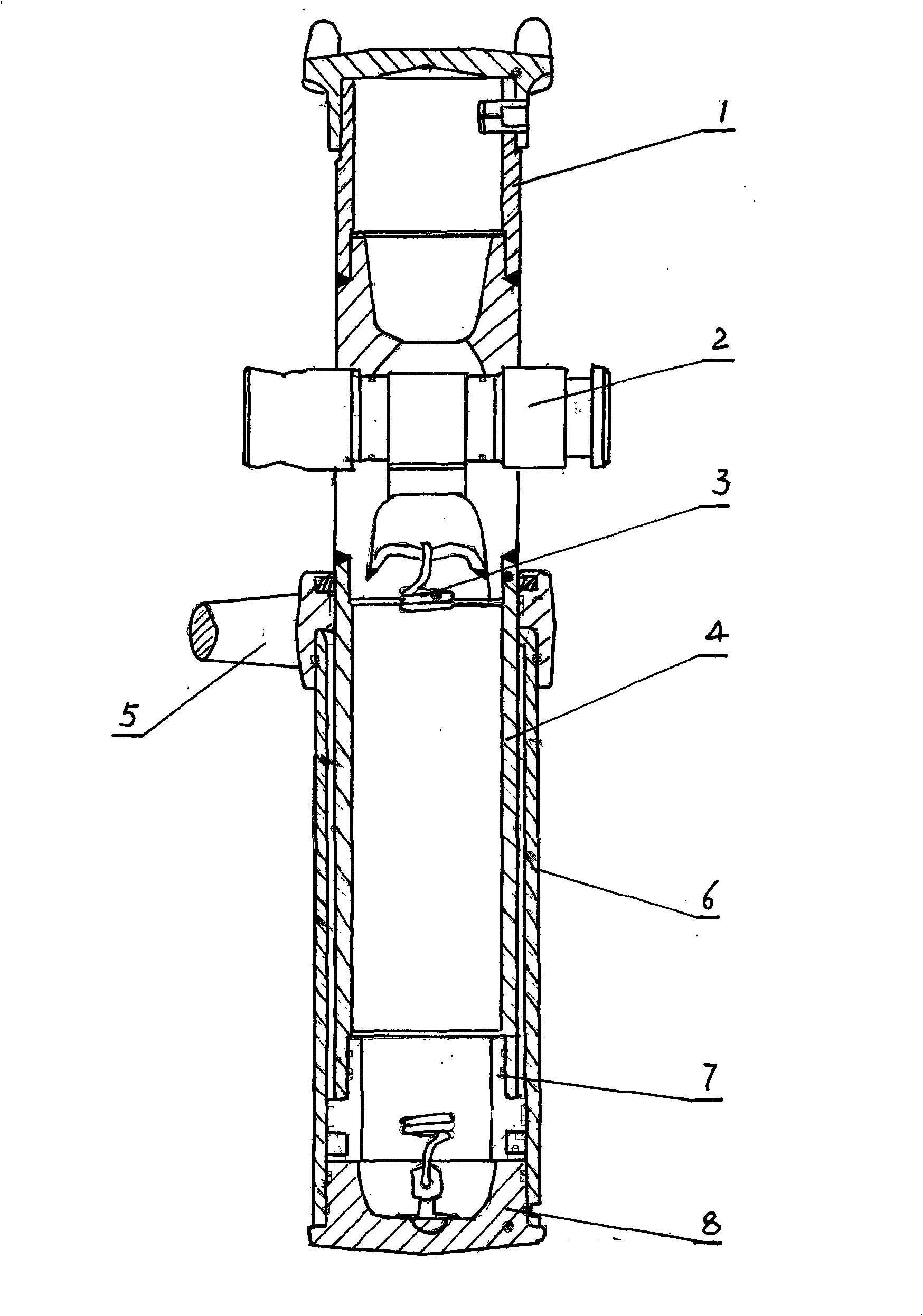

[0015] The single hydraulic prop used in the downhole of the present invention consists of a top cover 1, a three-purpose valve 2, a return spring 3, a live cylinder 4 (including a column head), a handle body 5, an oil cylinder 6, a piston or a retaining ring 7, a base body 8 and a seal parts and other components. The surface of the live cylinder 4 (including the surface of the valve hole at the column head), the surface of the left valve cylinder and the surface of the right valve cylinder of the three-purpose valve 2, and the surface of the oil cylinder 6 are coated with polyvinyl chloride coating through thermal melting and absorption, and the total thickness of the plastic coating layer is 0.32 ~0.45mm.

[0016] The processing method of above-mentioned polyvinyl chloride coating is:

[0017] The first step: the oil cylinder 6, the live cylinder 4 and the left and right valve workpieces of the three-purpose valve 2, which need to be treated with anti-corrosion and wear-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com