Vertical channel organic field effect transistor and method for producing the same

A technology of vertical channels and organic fields, applied in the field of organic electronics, to achieve the effect of reducing difficulty, reducing cost and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

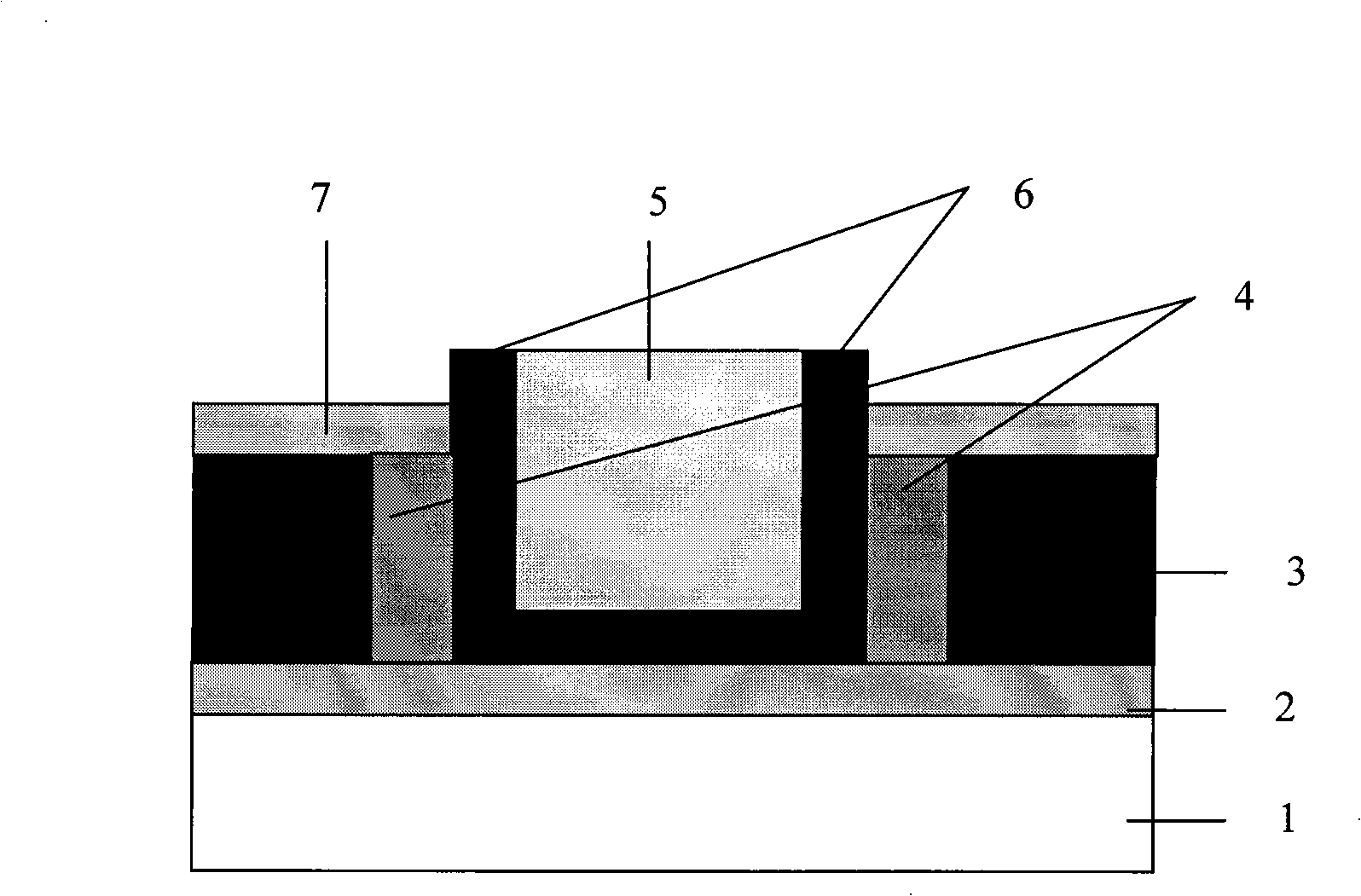

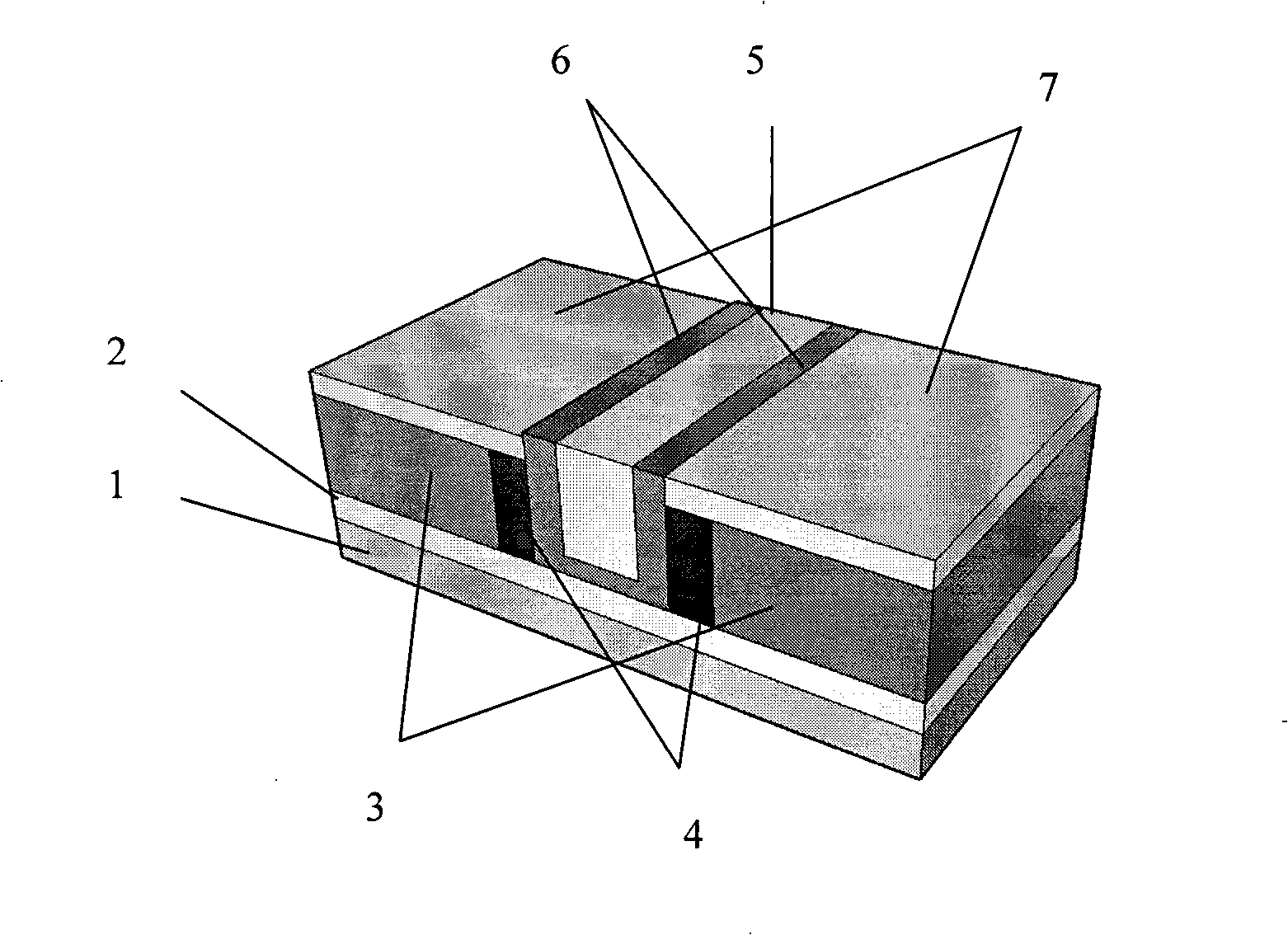

[0054] Depend on figure 1 As shown, the basic structure of the vertical channel organic field effect transistor of the present invention includes an insulating substrate, a metal gate electrode, a dielectric layer, an insulating layer for isolating source and drain electrodes, a vertical organic semiconductor layer, a planar metal source electrode and a planar metal drain electrode .

[0055] The insulating substrate is the base of this structure, and its manufacturing material is a silicon wafer with insulating films such as silicon oxide and silicon nitride, or insulating glass or insulating plastic film.

[0056] On the upper part of the insulating substrate is the source electrode, and the material of the source electrode can be a high-common function metal material such as gold, platinum or silver, or a conductive organic substance such as PEDOT:PSS. The source electrode is a planar electrode and is tiled on an insulating substrate.

[0057] The central part above the s...

Embodiment 2

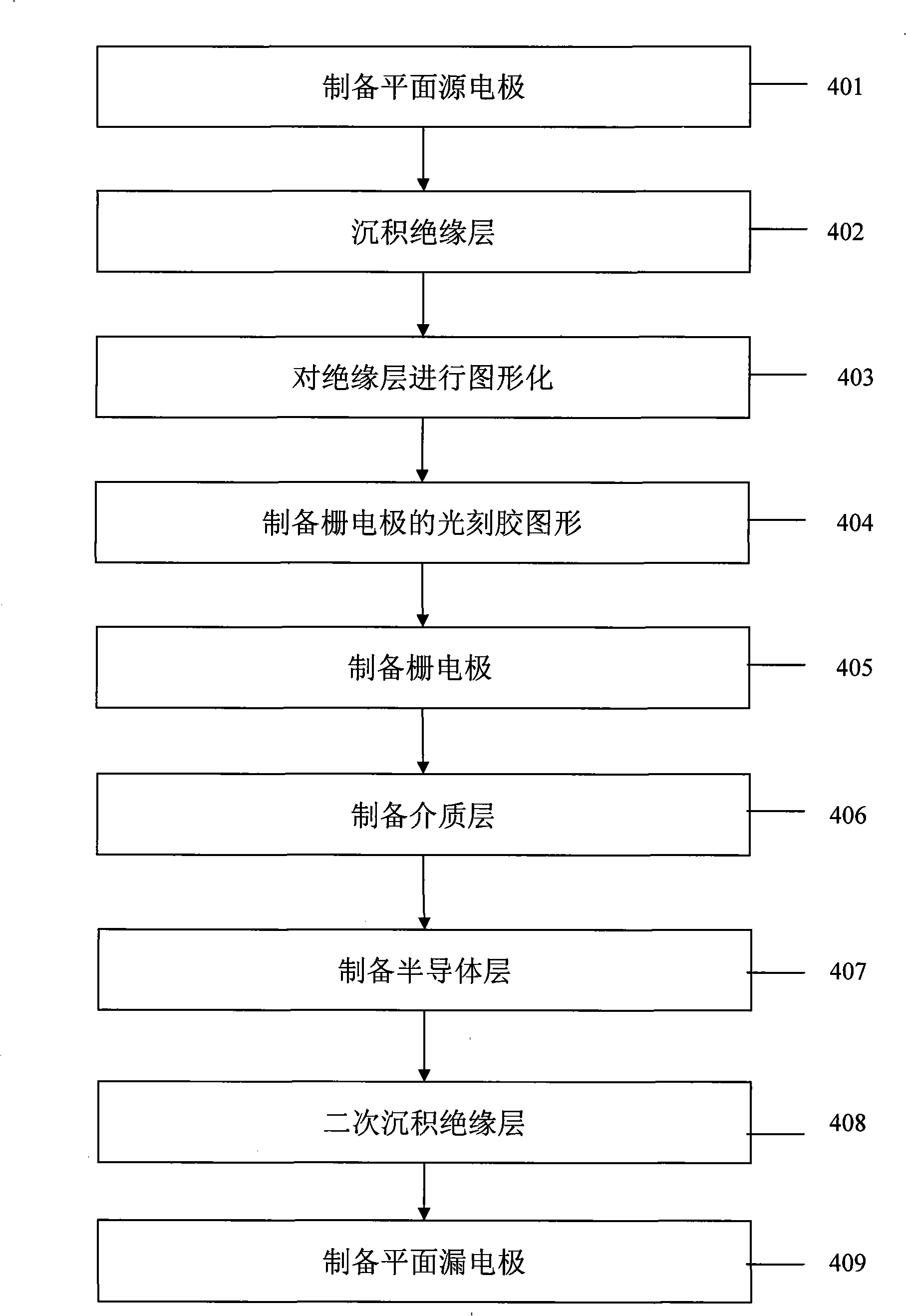

[0067] Such as image 3 As shown, the present invention also discloses a method for preparing a vertical channel organic field effect transistor, and its specific preparation steps are as follows:

[0068] see Figure 4 to Figure 12 .

[0069] Step 101: Prepare a planar gold source electrode on a thermally oxidized silicon insulating substrate. The specific preparation method of the planar source electrode used therein adopts the method of vacuum thermophysical deposition, electron beam deposition, sputtering metal electrode, ink-jet printing or spin-coating organic electrode.

[0070] Step 102: Deposit an insulating layer on the source electrode layer. The deposition method for the inorganic insulating layer is low-pressure chemical vapor deposition (LPCVD), sputtering or atomic layer deposition (ALD), etc.; the deposition method for the organic insulating layer is spin coating or inkjet printing. In this embodiment, an electron beam evaporation deposition method is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com