High dispersibility nano-scale poly (3,4-ehtylene dioxythiophene), preparation and use thereof

An ethylenedioxythiophene, nano-scale technology, applied in the direction of single-component synthetic polymer rayon, organic material conductor, fiber chemical characteristics, etc., can solve the problems of inhibiting the application and development of PEDOT, agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 3. The preparation method of the present invention is a self-assembly chemical oxidation polymerization method, which is simple and easy to implement, with simple equipment and is suitable for large-scale implementation.

[0032] 4. The nano-scale PEDOT provided by the present invention can be dissolved in an organic solvent to prepare a conductive film, and can also be blended with a variety of general-purpose polymer materials, and can also be used as a filler, and can be used in electronic devices, electroluminescence or electrochromism. Materials, anti-static materials, electromagnetic shielding materials, wave-absorbing materials, anti-corrosion materials, conductive fibers, etc. have been widely used.

Embodiment 1

[0035] Example 1 : Preparation of highly dispersed nano-scale PEDOT of the present invention

[0036] 0.5mL (0.0047mol) of EDOT monomer and 5.2g (0.023mol) of ammonium persulfate (oxidant) were sequentially added to an aqueous solution of trifluoroacetic acid (0.1mol) (dopant) at 0°C, so that doping The concentration of the oxidizing agent in the resulting reaction mixture solution was 5M, and the molar ratio of the EDOT monomer, oxidizing agent and dopant was 1:5:21. After stirring for 15 hours, the reaction was stopped, filtered under reduced pressure, and then washed three times with 10 mL of distilled water, ethanol and diethyl ether (i.e. three times with water, three times with ethanol and three times with diethyl ether), and vacuum dried at 60°C for 8 hours to obtain Blue black powder solid.

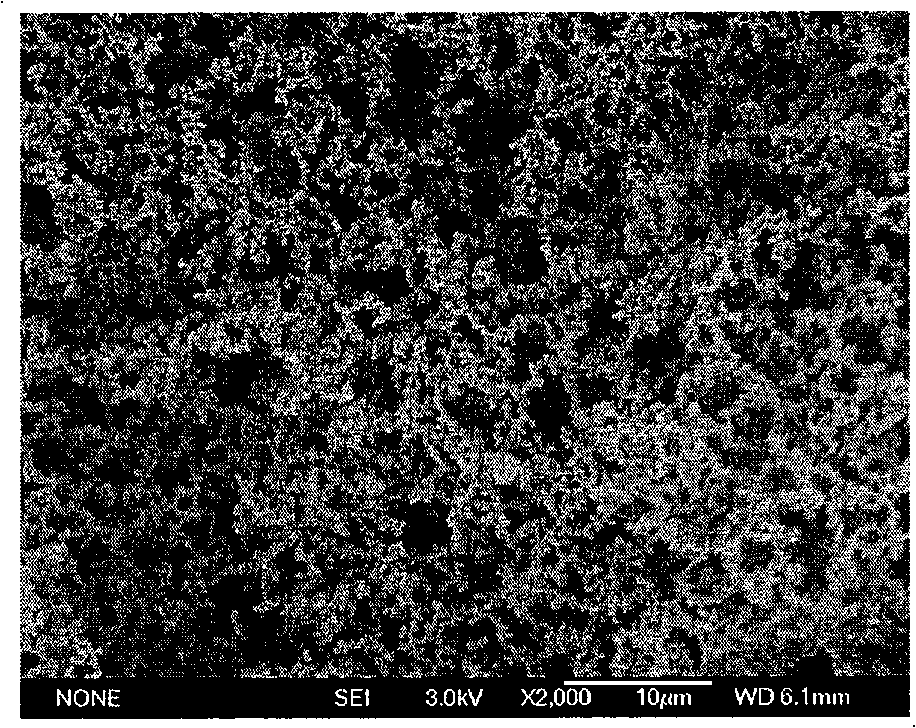

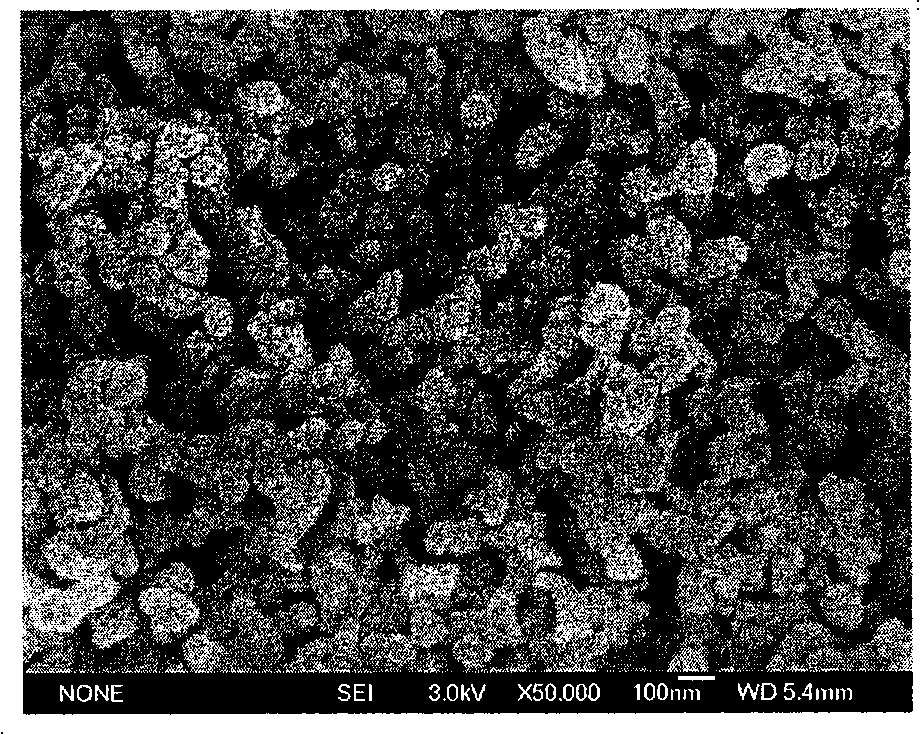

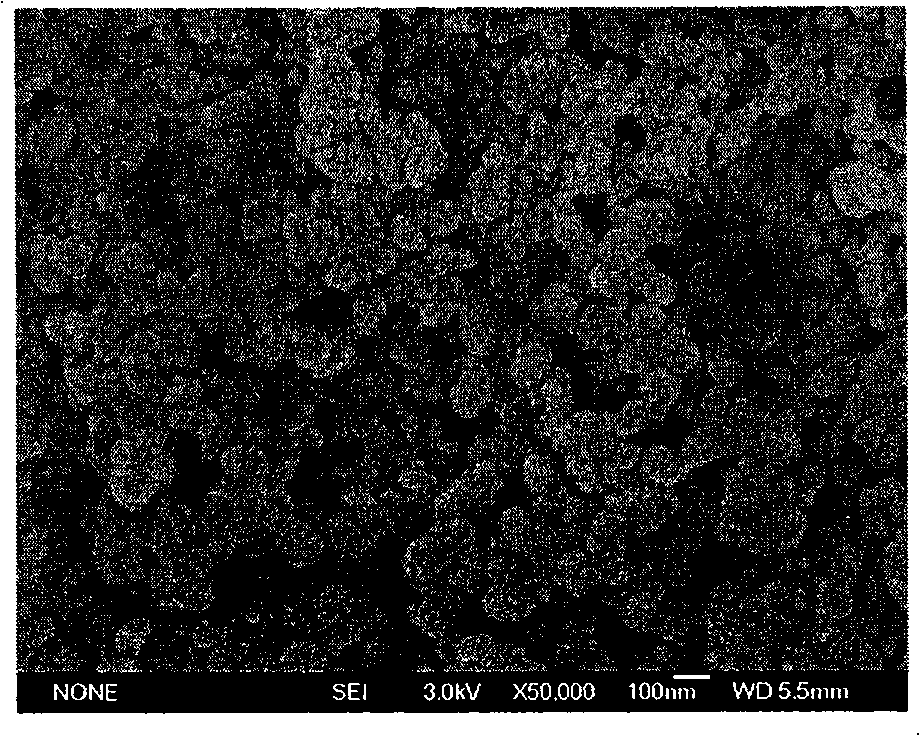

[0037] The results of infrared and ultraviolet spectra prove that it has the typical structure of PEDOT. The scanning electron micrograph of the newly prepared product is as f...

Embodiment 2

[0038] Example 2 : Preparation of highly dispersed nano-scale PEDOT of the present invention

[0039] 0.5mL (0.0047mol) of EDOT monomer and 2.6g (0.011mol) of ammonium persulfate (oxidant) were sequentially added to an aqueous solution of trifluoroacetic acid (0.1mol) (dopant) at 0°C, so that doping The concentration of the oxidizing agent in the resulting reaction mixture solution was 5M, and the molar ratio of the EDOT monomer, oxidizing agent and dopant was 1:2.5:21. After stirring for 15 hours, the reaction was stopped, filtered under reduced pressure, and then washed three times with 10 mL of distilled water, ethanol, and diethyl ether, and vacuum-dried at 60°C for 8 hours to obtain a blue-black powder solid.

[0040] The results of infrared and ultraviolet spectra prove that it has the typical structure of PEDOT. The diameter of the obtained particles is in the range of 50-150nm, the room temperature conductivity measured by the four-probe electrode method is 100S / cm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com