Solid-state cardanol and preparation thereof

A cardanol, solid-state technology, applied in the field of preparation of the solid-state cardanol, can solve the problems of self-polymerization, perishability, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

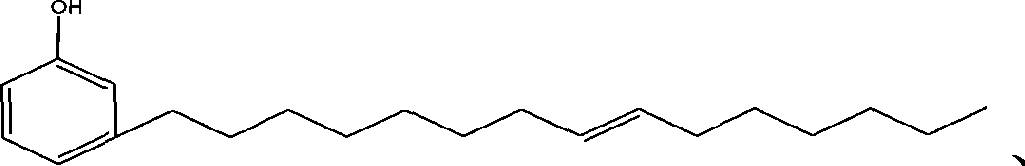

[0034] The composition of solid cardanol is cardanol with saturated side chain.

[0035] Preparation method: put cardanol into an autoclave, add a skeleton nickel catalyst, the amount of the skeleton nickel catalyst is 0.2% of the mass of cardanol, first pass nitrogen to discharge the air in the autoclave, and then pass hydrogen into the autoclave, at 100 ℃, 1MPa The reaction was stirred for 3 hours at a stirring speed of 200 r / min; after the reaction was completed, the product was collected, and then subjected to vacuum distillation with a vacuum degree of 0.0900 MPa and a tower top temperature of 196° C. After cooling the distillate, solid cardanol was obtained.

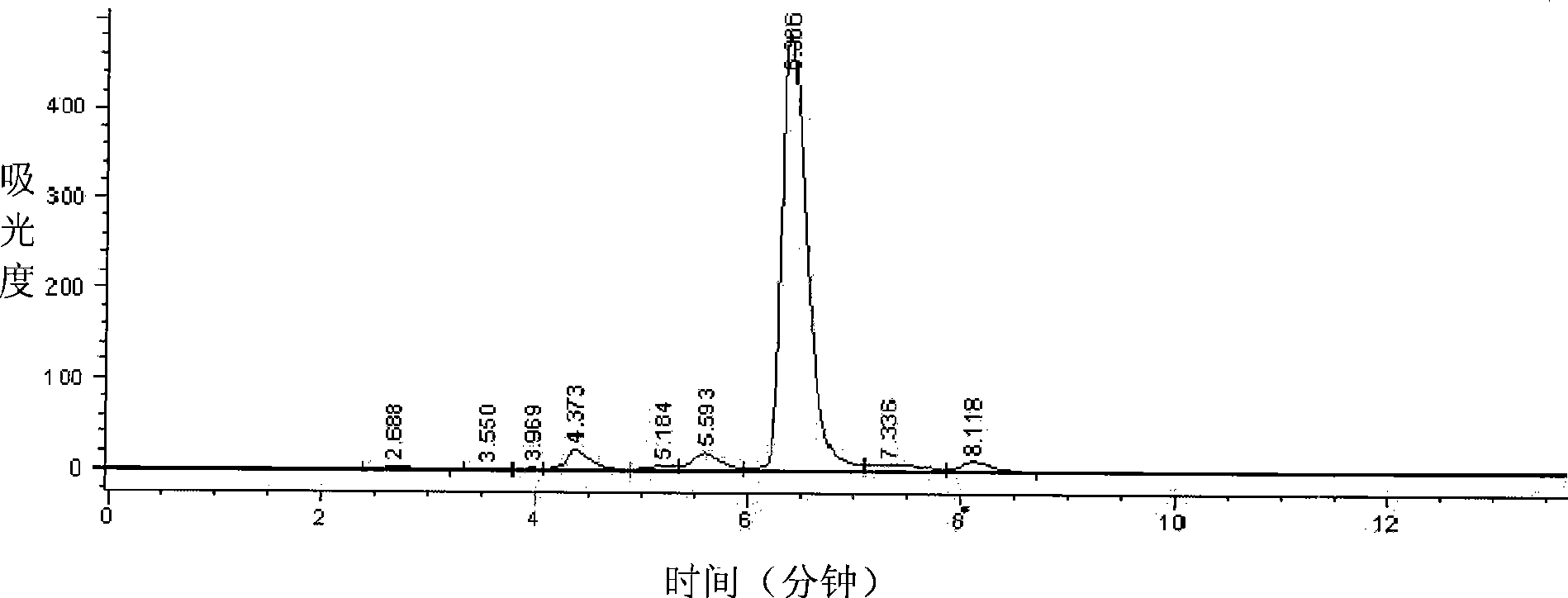

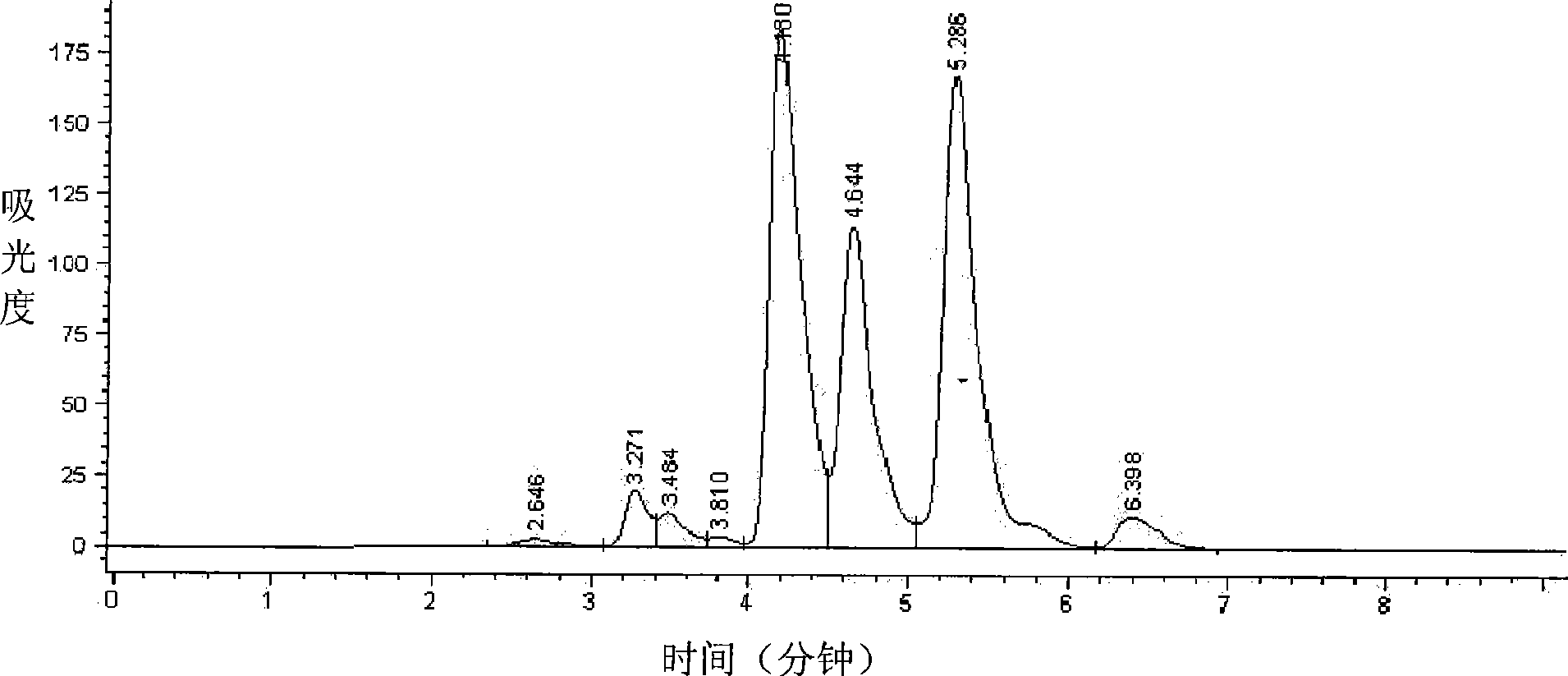

[0036] The liquid phase analysis chromatogram of gained product solid cardanol is as figure 2 Shown, compare the liquid chromatogram of existing liquid cardanol (raw material) figure 1 Analyzed, the side chain unsaturated cardanol characteristic peaks of 4.18min, 4.644min0, and 5.286min in the raw material cardan...

Embodiment 2

[0040] The composition of solid cardanol is cardanol with saturated side chain.

[0041] Preparation method: put cashew nut oil into an autoclave, add copper-based catalyst, the amount of copper-based catalyst is 1% of the mass of cashew nut oil, then continuously feed hydrogen, stir and react at 200°C and 2MPa for 4.5 hours, and the stirring speed is 400r / min; collect the product after the reaction is completed, and then carry out vacuum distillation. The vacuum degree of the distillation is 0.0965 MPa, the temperature at the top of the tower is 215°C, and the solid cardanol is obtained after the distillate is cooled to room temperature.

Embodiment 3

[0043] The composition of solid cardanol is cardanol with saturated side chain.

[0044] Preparation method: put cardanol into an autoclave, add rhodium carbon catalyst, the amount of rhodium carbon catalyst is 2% of the mass of cardanol, first pass carbon dioxide to discharge the air in the autoclave, and then pass in hydrogen, at 200 ℃, 5MPa The reaction was stirred for 6 hours, and the stirring speed was 600r / min; after the reaction was completed, the product was collected, and then subjected to vacuum distillation, the vacuum degree of distillation was 0.0995MPa, the temperature of the tower top was 237°C, and the distillate was cooled to normal temperature to obtain solid cardanol .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com