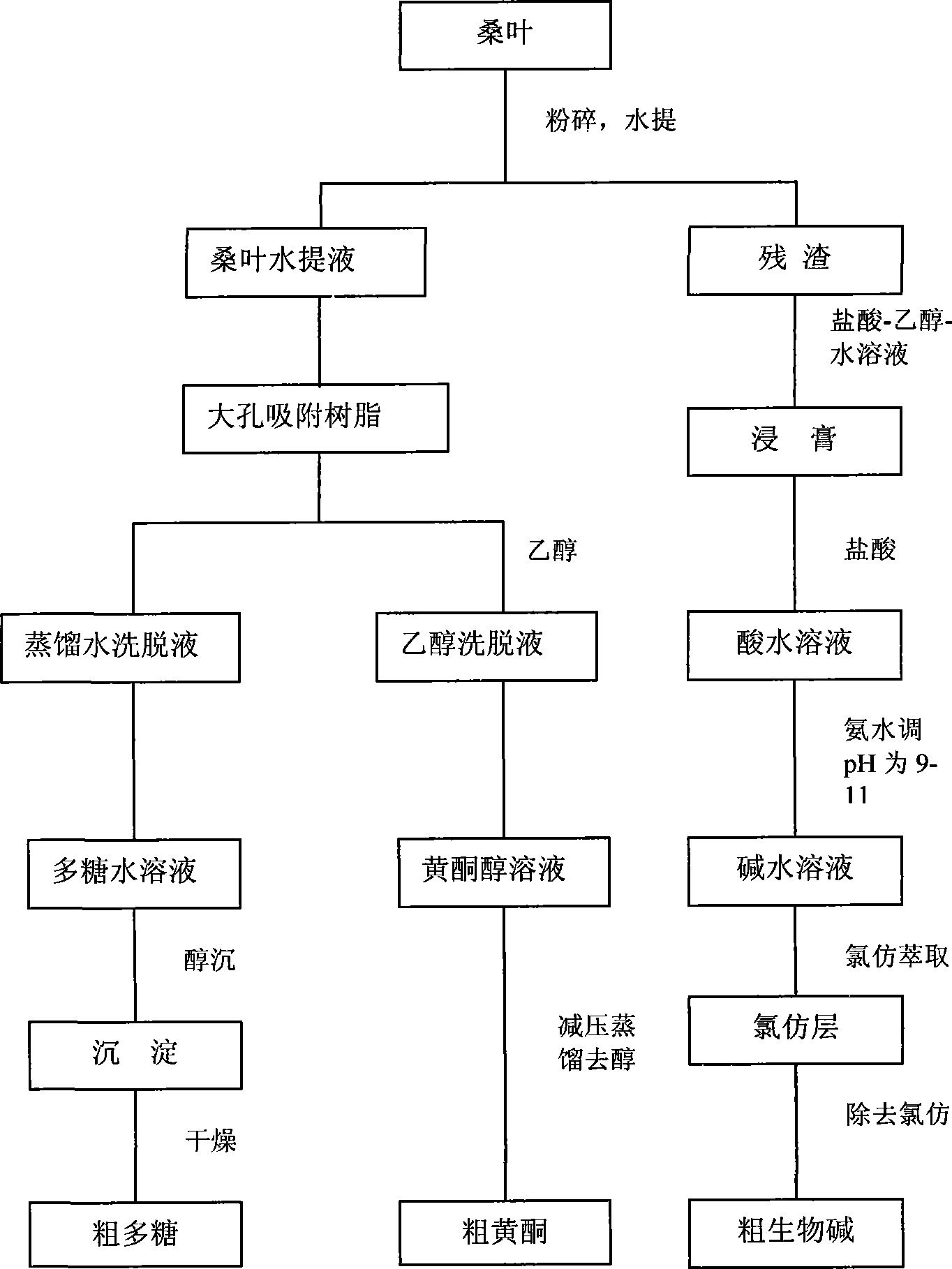

Composite extracting technique for coproduction of mulberry tea flavone, polysaccharide and alkaloid

A technology for compound extraction of mulberry leaf flavonoids, applied in the direction of alkaloids, alkaloids, drug combinations, etc., can solve the problems of co-production of mulberry leaf flavonoids, polysaccharides and alkaloids, and the composite process and application research of three active substances Lack of basic data and other issues to achieve the effect of improving medicinal utilization and economic added value, easy to scale up industrial production, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] White mulberry leaves are selected as raw materials, washed and dried at 60°C until they become brittle, crushed and sieved (with a sieve diameter of 40-80 mesh) to obtain mulberry leaf powder. Extract the mulberry leaf powder with water at a temperature of 60°C, a solid-to-liquid ratio of 1:10, and a pH of 7, then filter to obtain the mulberry leaf water extract and mulberry leaf residue, and add the mulberry leaf residue to hydrochloric acid-ethanol at a solid-to-liquid ratio of 1:10 -Aqueous solution (containing 1% hydrochloric acid, 40% ethanol, volume fraction), extracting to obtain a solution containing mulberry leaf alkaloids, the content of mulberry leaf flavonoids in the obtained mulberry leaf water extract is 2.5mg / mL, and the content of mulberry leaf polysaccharides is 2.0mg / mL. After the obtained mulberry leaf water extract is adsorbed by a cross-linked polystyrene macroporous adsorption resin column, the resin column is first eluted to colorless with disti...

Embodiment 2

[0031]The mulberry leaf is selected as raw material, washed and dried at 60°C until it becomes brittle, crushed and sieved (with a sieve diameter of 40-80 mesh) to obtain the mulberry leaf powder. Extract the mulberry leaf powder with water at a temperature of 90°C, a solid-to-liquid ratio of 1:50, and a pH of 10, and then filter to obtain the mulberry leaf water extract and mulberry leaf residue. Add the mulberry leaf residue to hydrochloric acid-ethanol at a solid-to-liquid ratio of 1:50 -Aqueous solution (containing 3% hydrochloric acid, 80% ethanol, volume fraction), extracting to obtain a solution containing mulberry leaf alkaloids, the content of mulberry leaf flavonoids in the obtained mulberry leaf water extract is 3.2mg / mL, and the content of mulberry leaf polysaccharides is 2.8mg / mL. After the obtained mulberry leaf water extract is adsorbed by a cross-linked polystyrene macroporous adsorption resin column, the resin column is first eluted to colorless with distille...

Embodiment 3

[0033] The mulberry leaf is selected as the raw material, washed and dried at 60° C. until it becomes brittle, crushed and sieved (with a sieve diameter of 40 to 80 mesh) to obtain the mulberry leaf powder. Extract the mulberry leaf powder with water at a temperature of 85°C, a solid-to-liquid ratio of 1:40, and a pH of 8, and then filter to obtain the mulberry leaf water extract and mulberry leaf residue. Add the mulberry leaf residue to hydrochloric acid-ethanol at a solid-to-liquid ratio of 1:30 -Aqueous solution (containing hydrochloric acid 1.5%, ethanol 65%, volume fraction), extraction obtains the solution containing the total alkaloids of mulberry leaves, the total flavonoid content of mulberry leaves in the obtained mulberry leaf water extract is 2.8mg / mL, and the total polysaccharide content of mulberry leaves It was 2.9 mg / mL. After the obtained mulberry leaf water extract is adsorbed by a cross-linked polyacrylate macroporous adsorption resin column, the resin colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com