Method for improving wheat plantule protein capability with supersonic wave

A wheat germ protein and wheat germ technology, applied in the field of bioengineering, can solve the problems of low functional properties of wheat germ albumin and globulin, and achieve the effects of short processing time, simple operation and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Comparison of wheat germ albumin extraction with traditional albumin extraction methods:

[0020] Traditional method: Dissolve defatted wheat germ powder in water at a concentration of 10% (w / v), use 25 U / g of α-amylase to enzymolyze at 50°C for 120min, and keep stirring during the enzymolysis process. After the enzymatic hydrolysis, the supernatant obtained by centrifugation was centrifuged. The supernatant was salted out with 60% (w / v) ammonium sulfate, and the albumin precipitate was obtained after centrifugation, and the albumin was desalted by dialysis, and the albumin powder was obtained after spray drying. The albumin yield obtained by this method was 22.0% (w / w), the protein purity was 57.6% (w / w).

[0021] Improved method: Dissolve defatted wheat germ powder in water at a concentration of 10% (w / v), use 25 U / g of α-amylase to enzymolyze it at 50° C. for 120 minutes, and keep stirring during the enzymolysis process. After the enzymatic hydrolysis, the supernat...

Embodiment 2

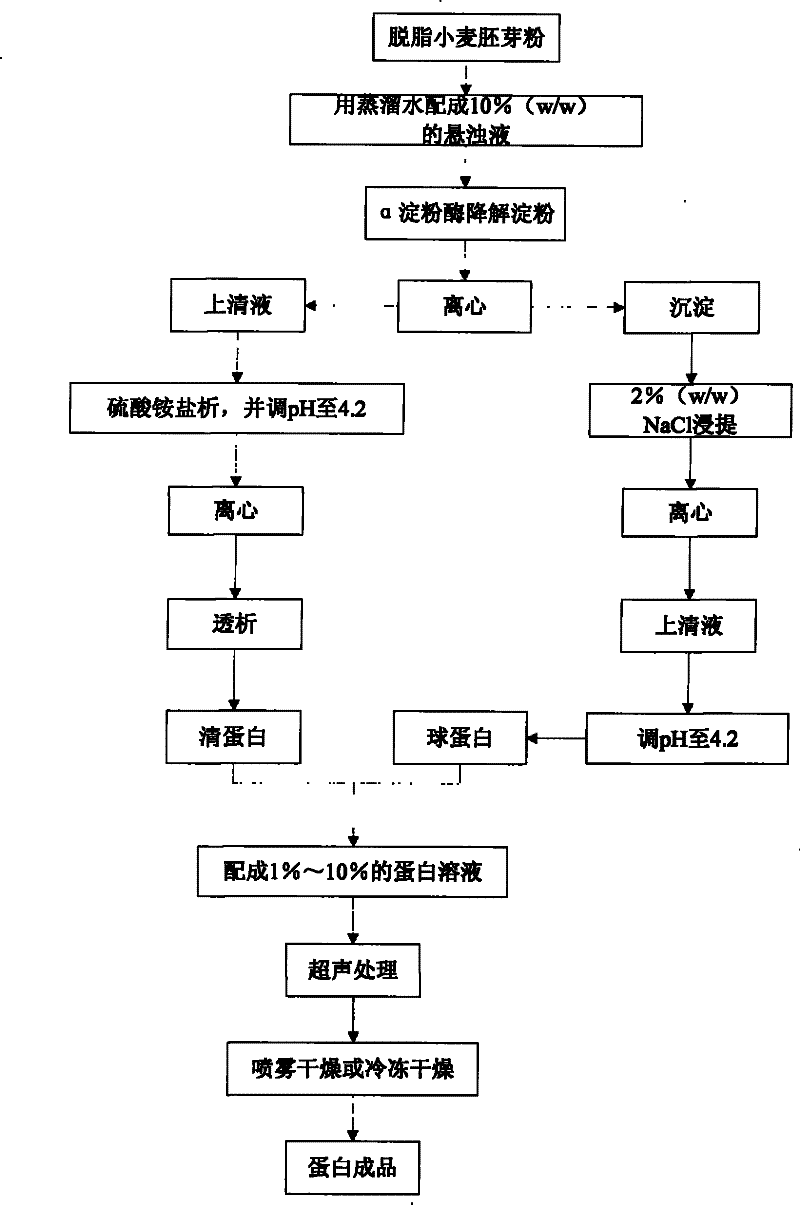

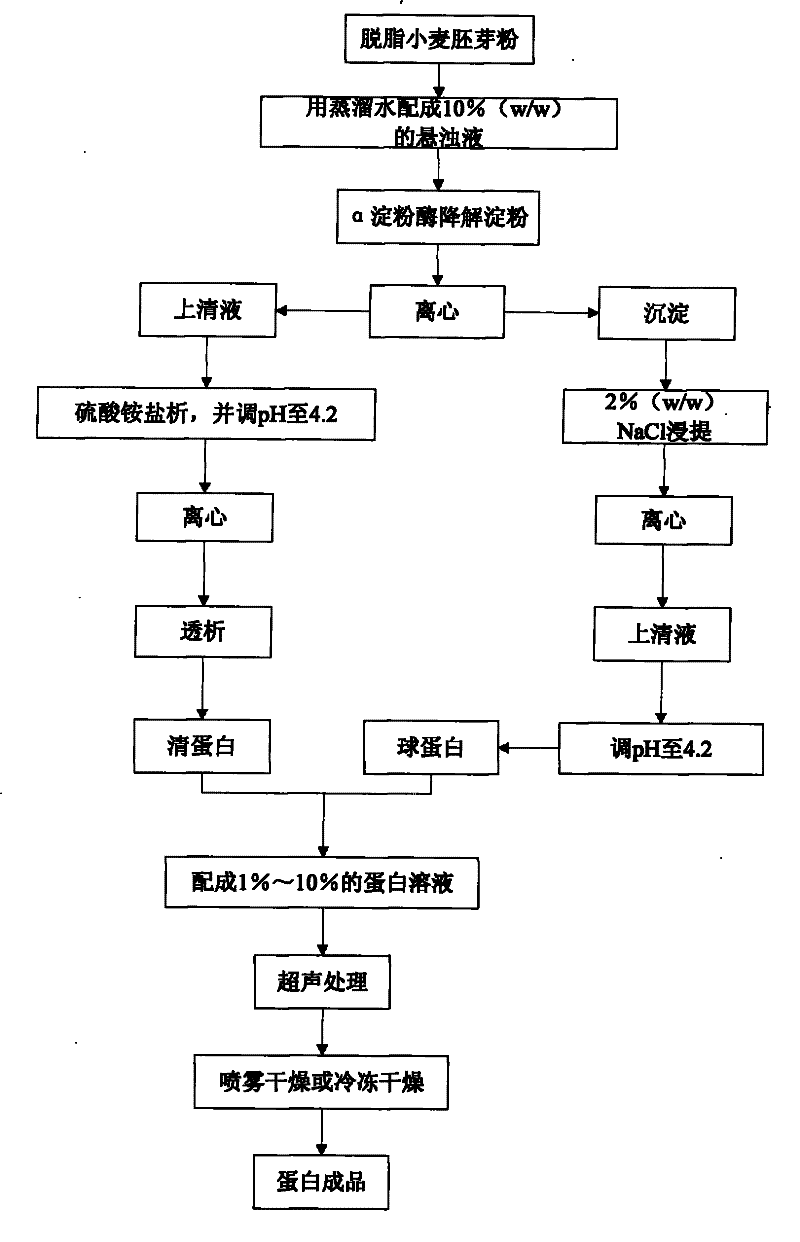

[0024] The experimental operation process is as figure 1 As shown, the defatted wheat germ powder was dissolved in water at a concentration of 10% (w / v), and the enzymatic hydrolysis was carried out at 50° C. for 120 minutes with α-amylase with an enzyme content of 25 U / g, and the process of enzymatic hydrolysis was continuously stirred. After the enzymatic hydrolysis, the obtained supernatant A and precipitate A were centrifuged. Supernatant A was salted out with 35% (w / v) ammonium sulfate, and its pH was adjusted to 4.2 at the same time. After centrifugation, the albumin precipitate was obtained, and the albumin was desalted by dialysis, and the albumin powder was obtained after spray drying. The protein yield was 25.3% (w / w), and the protein purity was 59.4% (w / w); Precipitation A was extracted with 2% (w / v) NaCl at 50°C for 120min, and the supernatant after centrifugation was adjusted to pH 4.2. Wheat germ globulin was obtained after centrifugation, and globulin powder wa...

Embodiment 3

[0043] The extraction of wheat germ albumin and globulin is the same as the method in Example 2, and the ultrasonic treatment method is as follows:

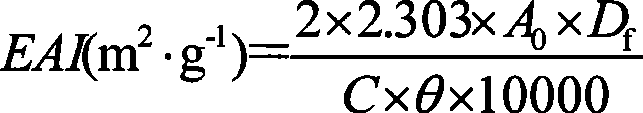

[0044] Take 100 mL of 5% (w / v) wheat germ albumin or globulin samples, adjust their pH to 7.0, and treat them with 25kHz ultrasonic waves for 35 minutes. The ultrasonic power is: albumin 10W / mL, globulin 12.5W / mL, The ultrasonic sound is continuous for 2s and intermittent for 2s, and the temperature of the treatment liquid should be kept at 4±1°C. The protein suspension of above-mentioned treatment carries out solubility test, foamability test and emulsification stability test respectively after freeze-drying, and assay method is the same as the method in embodiment 2, and assay result is shown in Table 2:

[0045] Table 2 Effect of ultrasonic treatment on the functional properties of 5% (w / v) wheat germ albumin and globulin

[0046]

[0047] It can be seen from Table 2 that after ultrasonic treatment, the solubility of wheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com