Catalyst selective oxidation reaction of hydrogen gas

An oxidation reaction and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, etc., can solve the loss of raw materials for dehydrogenation compounds, poor selectivity, low activity, etc. problem, to achieve the effect of shortened residence time, thin effective active layer and high combustion activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

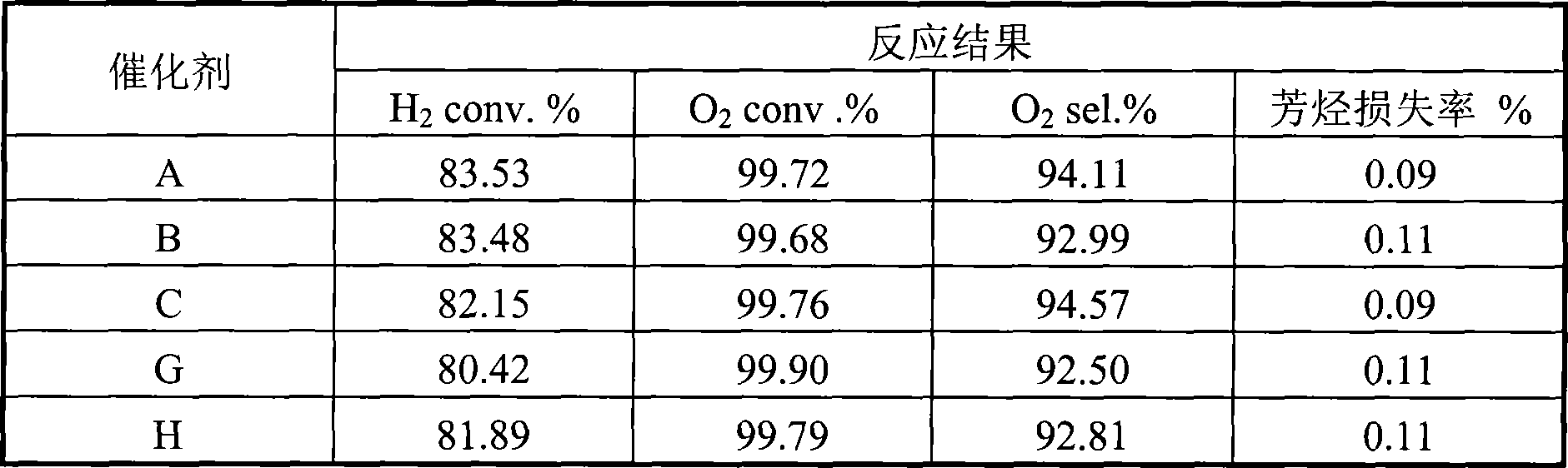

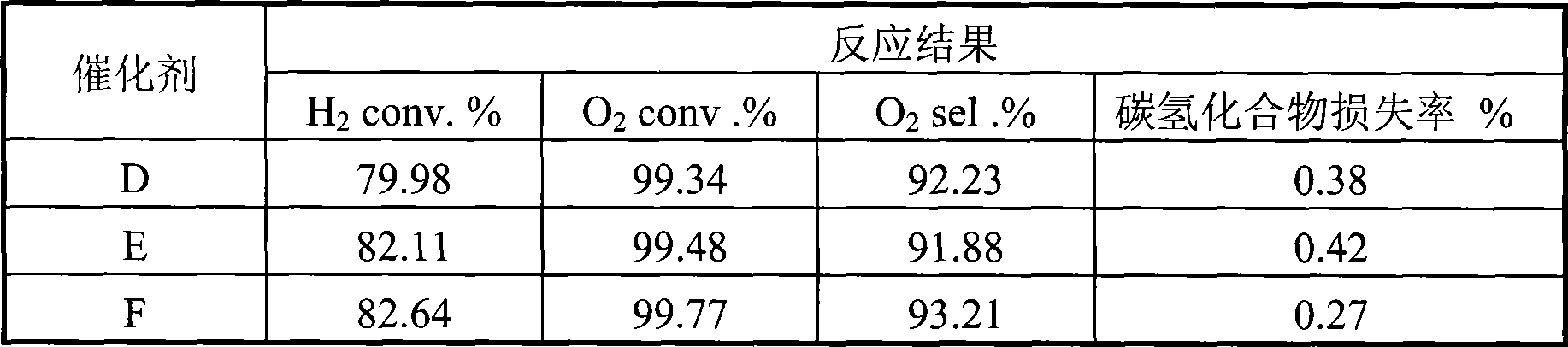

Examples

Embodiment 1

[0016] 40 grams of alumina sol (containing 15% alumina by mass ratio), 60 grams of 2% polyvinyl alcohol solution, and 0.5 grams of Tween were prepared into a slurry. Then add 0.4 grams of calcium silicate and 40 grams of γ-Al with a particle size of 100 microns or less to this mixture. 2 o 3 pink. After stirring for about ten minutes, 1.5 grams of 50% tin tetrachloride aqueous solution was added, and the obtained slurry was ball milled at room temperature for 4 hours to control the particle size below 10 microns. Slurry spraying to α-Al with a particle size of 4 mm 2 o 3 On the sphere, dry at 80°C for 2 hours, then heat up to 100°C and dry again for 2 hours, and finally bake at 1050°C for 8 hours to obtain a layered composite carrier. The scanning electron microscope shows that the thickness of the coating is about 80 microns, and the specific surface area of the coating is 73 meters 2 / gram.

[0017]Dissolve lithium nitrate, sodium nitrate and chloroplatinic acid in w...

Embodiment 2

[0019] 40 grams of alumina sol (containing 15% by mass of alumina), 60 grams of 3% cyclodextrin solution, and 0.2 grams of tetraethylammonium bromide were prepared into a slurry. Then add 0.3 grams of potassium feldspar and 40 grams of θ-Al with a particle size of 100 microns or less to this mixture. 2 o 3 pink. After stirring for about ten minutes, add 2.0 grams of 50% tin dichloride and 1.1 grams of MgCl 2 As an aqueous solution, the resulting slurry was ball milled for 4 hours at room temperature to control the particle size below 10 microns. The slurry was sprayed onto magnesium-aluminum spinel spheres with a particle size of 4 mm, dried at 80°C for 2 hours, then heated to 150°C and dried again for 2 hours, and finally calcined at 1000°C for 10 hours to obtain a layered composite carrier. The scanning electron microscope shows that the thickness of the coating is about 120 microns, and the specific surface area of the coating is 105 meters 2 / gram.

[0020] Dissolve...

Embodiment 3

[0022] 35 grams of alumina sol (containing 25% mass ratio of alumina), 5 grams of 40% silica sol, 60 grams of 4% carboxyethyl cellulose solution, 1.0 grams of P123 (water-soluble polyoxyethylene-polyoxypropylene - polyoxyethylene triblock copolymer, trade name Pluronics) made into slurry. Then add 0.4 grams of calcium silicate and 40 grams of δ-Al with a particle size of 100 microns or less to this mixture. 2 o 3 pink. After stirring for about ten minutes, 2.5 grams of 50% tin tetrachloride and 1 gram of 8% lead nitrate aqueous solution were added, and the obtained slurry was ball milled at room temperature for 4 hours to control the particle size below 10 microns. The slurry was sprayed onto cordierite spheres with a particle size of 4 mm, dried at 80°C for 2 hours, then heated to 150°C and dried again for 2 hours, and finally calcined at 1200°C for 2 hours to obtain a layered composite carrier. Scanning electron microscopy shows that the thickness of the coating is about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com