Process for producing easily dispersable duoparental nano-silicon dioxide

A nano-silica, silicon dioxide technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of complex process, larger particle size, particle agglomeration, etc., and achieve good powder dispersion, reduced particle agglomeration, The effect of good parental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

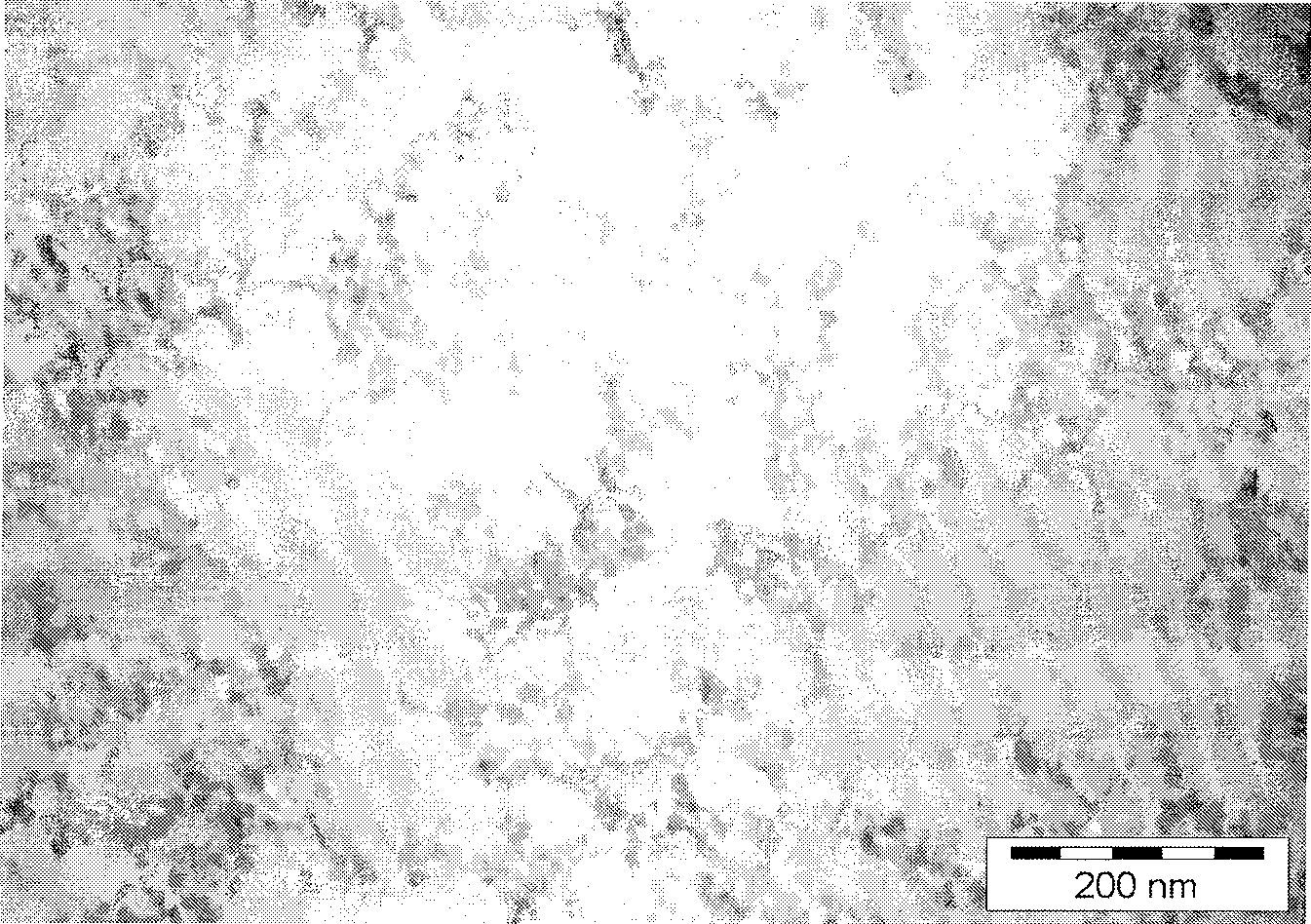

Image

Examples

Embodiment 1

[0022] (1) Add 600g of 25wt% sodium silicate aqueous solution into a 1000ml three-necked flask, and control the temperature at 52±2°C. Add 12 g of bis(dioctyl pyrophosphate) glycolate titanate, keep the temperature and stir for 1 h.

[0023] (2) One-step reaction: Slowly and uniformly drop 12% (wt) hydrochloric acid (dropped within 40 minutes), adjust the pH value of the reaction solution to 8, stop adding acid, and stir at constant temperature for 1 hour.

[0024] (3) Two-step reaction: continue to heat up to 75±2°C, add 6g of bis(dioctylpyrophosphate) glycolate titanate, stir for 30min, and then slowly and uniformly drop in 12% (wt) dilute hydrochloric acid , until the pH value of the reaction system was adjusted to 6, stop adding acid. Maintain constant temperature and stir for 1h.

[0025] (4) The reaction liquid is filtered and washed.

[0026] (5) Heat the washed precipitated silica to 180°C in a vacuum drying oven and dry for 4 hours to obtain easily dispersible amph...

Embodiment 2

[0028] (1) Add 600g of 30% (wt) sodium silicate aqueous solution into a 1000ml three-necked flask, and control the temperature at 55±2°C. Add 20 g of bis(dioctyloxypyrophosphate) ethylene titanate, keep the temperature and stir for 1 h.

[0029] (2) One-step reaction: Slowly and uniformly drop 15% (wt) hydrochloric acid (dropped within 20 minutes), adjust the pH value of the reaction solution to 8, stop adding acid, and stir at constant temperature for 1 hour.

[0030] (3) Two-step reaction: continue to heat up to 75±2°C, add 10 g of bis(dioctyloxypyrophosphate)ethylene titanate, stir for 30 minutes, and then slowly and uniformly drop in 15% dilute hydrochloric acid until the reaction system When the pH value is adjusted to 6.5, stop adding acid. Maintain constant temperature and stir for 1h.

[0031] (4) The reaction liquid is filtered and washed.

[0032] (5) Heat the washed precipitated silica to 160°C in a vacuum drying oven and dry for 6 hours to obtain easily dispersi...

Embodiment 3

[0034](1) Add 600g of 25% (wt) sodium silicate aqueous solution into a 1000ml three-necked flask, and control the temperature at 58±2°C. Add 20g of chelated phosphate titanium coupling agent quaternary ammonium salt, keep the temperature and stir for 1h.

[0035] (2) One-step reaction: Slowly and uniformly drop 12% (wt) hydrochloric acid (dropped within 50 minutes), when the pH value of the reaction solution is adjusted to 8.5, stop adding acid, and stir at constant temperature for 1 hour.

[0036] (3) Two-step reaction: continue to heat up to 78±2°C, add 10g of chelated phosphate titanium coupling agent quaternary ammonium salt, stir for 30min, then slowly and uniformly drop in 12% dilute hydrochloric acid again until the pH value of the reaction system is adjusted At 6 o'clock, stop adding acid. Maintain constant temperature and stir for 1h.

[0037] (4) The reaction liquid is filtered and washed.

[0038] (5) Dry the washed precipitated silica in a microwave drying oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com