Method for producing Epsilon-hexanolactam with cyclohexanone oxime gas-phase beckmann rearrangement

A Beckmann rearrangement, cyclohexanone oxime technology, applied in the preparation of lactams, chemical instruments and methods, chemical recovery and other directions, can solve the problems of catalyst deactivation, short catalyst life, unable to meet the requirements of industrialization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

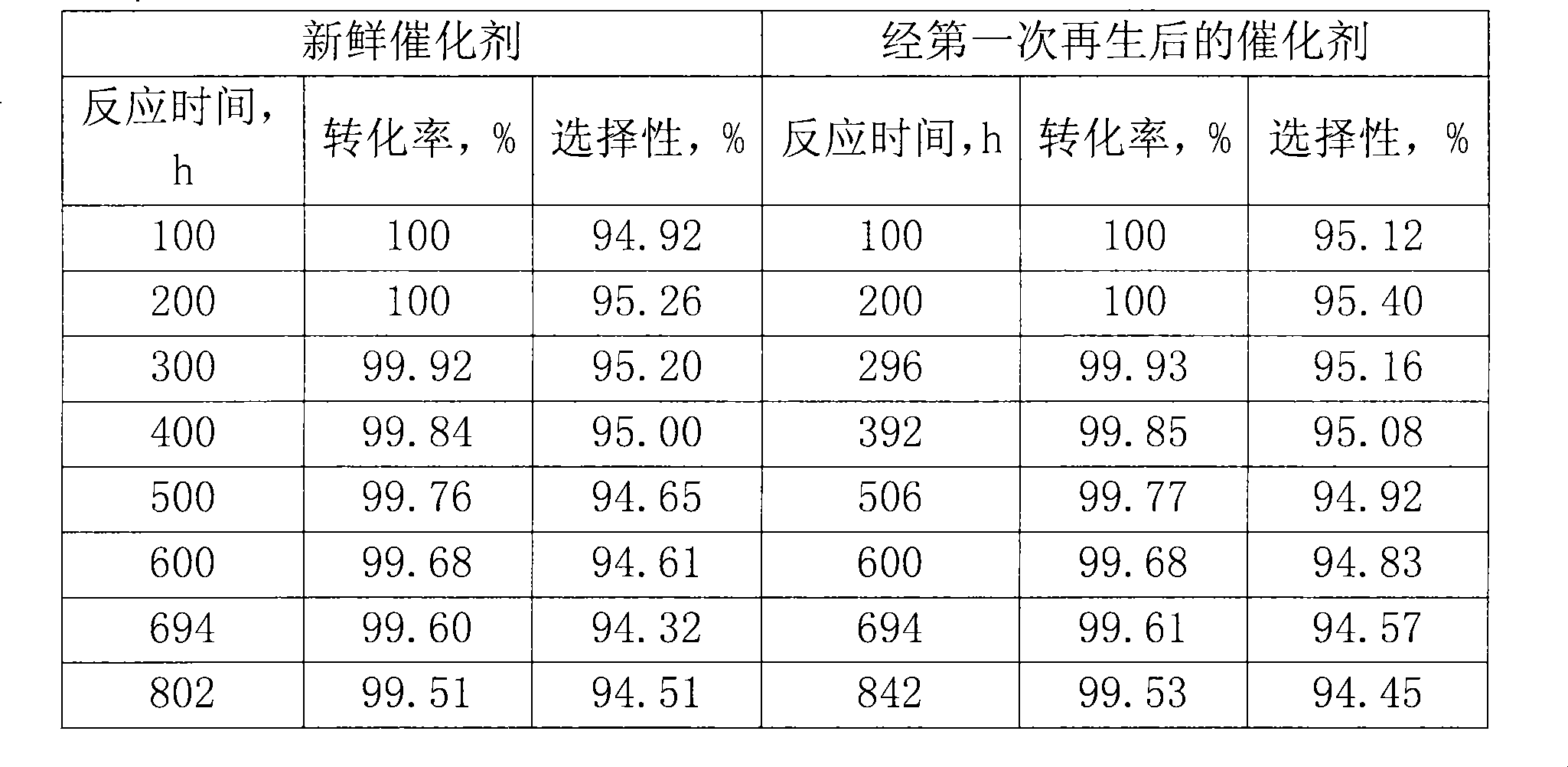

[0024] The gas-phase Beckmann rearrangement reaction of cyclohexanone oxime is carried out in an 80ml fixed-bed reactor, the inner diameter of the reactor is 28mm, and the catalyst loading capacity of the MFI structure is 20.0g catalyst (produced by Hunan Jianchang Petrochemical Co., Ltd., batch number RBS-1 , is Φ1.8mm strip shape, the bed height is 19cm, and the specific surface area is 319m 2 g -1 , the micropore specific surface area is 273m 2 g -1 , the non-microporous specific surface area is 46m 2 g -1 ; Pore volume 0.414ml / g, micropore volume 0.133ml / g).

[0025] Reaction pressure 0.1MPa, catalyst bed reaction temperature 365°C-385°C, carrier gas flow rate 4-8L / gcat / hr, vaporizer temperature control 185°C, vaporizer core 190°C, pipeline insulation 185°C, cyclohexanone oxime WHSV for 1h -1 , in the cyclohexanone oxime-methanol mixture, the concentration of cyclohexanone oxime is 35% (weight), and the water content of the reaction raw material is: 1.6% (m).

[002...

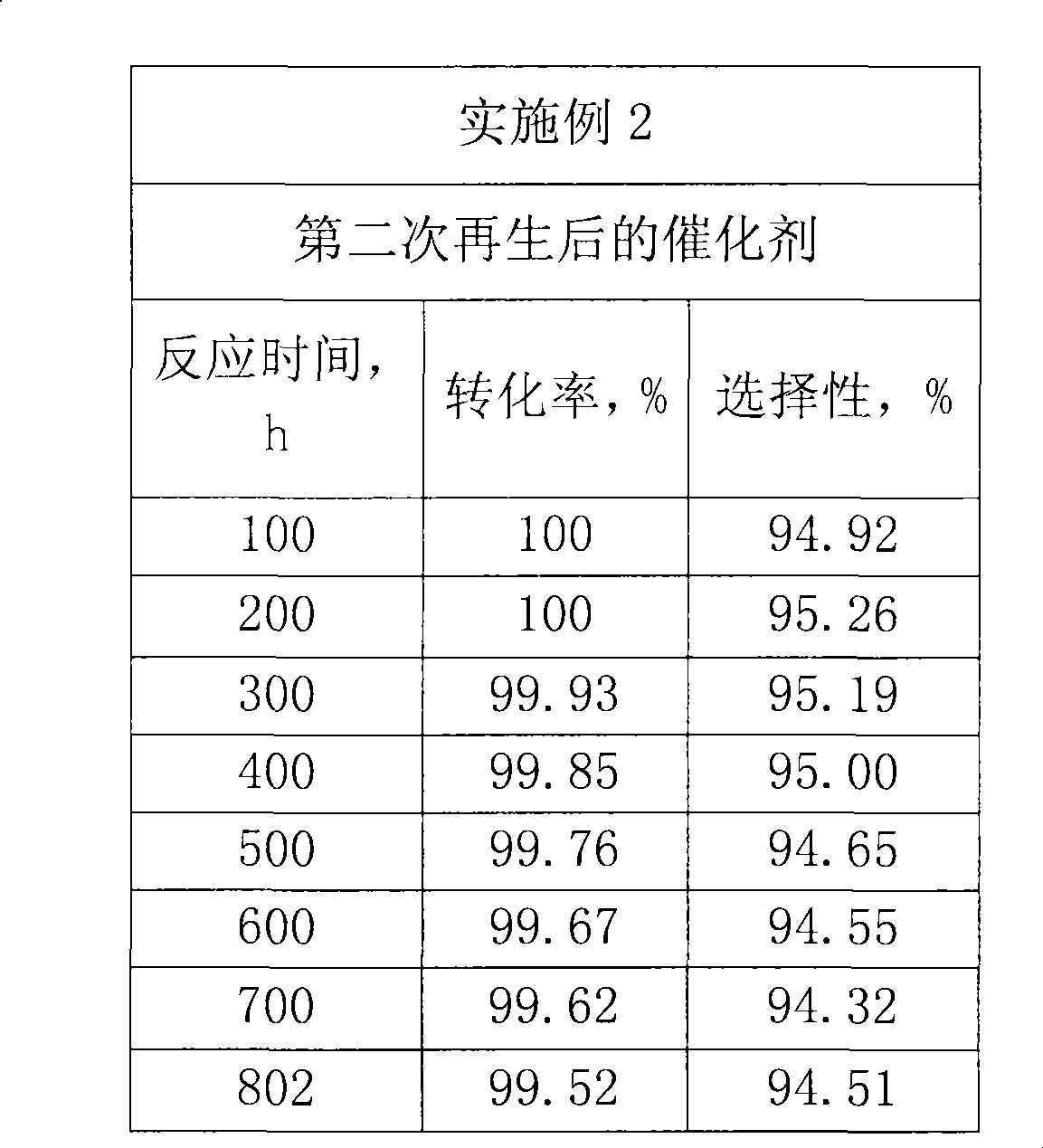

Embodiment 2

[0037] After about 802 hours of reaction through the regenerated catalyst of embodiment 1, the conversion rate of cyclohexanone oxime dropped to 99.50%. At this moment, the catalyst specific surface area was recorded as 215m 2 g -1 , at which point the weight of the catalyst increased by 11.5%. The addition of the cyclohexanone oxime-methanol mixture was stopped, purging was carried out under the condition of a nitrogen flow rate of 6L / gcat / hr, and methanol (3g / gcat / hr) was introduced at the same time, and the temperature of the reactor was lowered to 340°C. Then, the feed gas is converted from nitrogen to air (air flow rate is 8L / gcat / hr), the catalyst is heat-treated for 5 hours, and the deactivated catalyst is regenerated at a temperature of 500°C for 36 hours, and the specific surface area of the catalyst is restored to 325m 2 g -1 .

[0038] After regeneration of the deactivator, the BET specific surface area was restored. The catalyst is unloaded, and the buffer so...

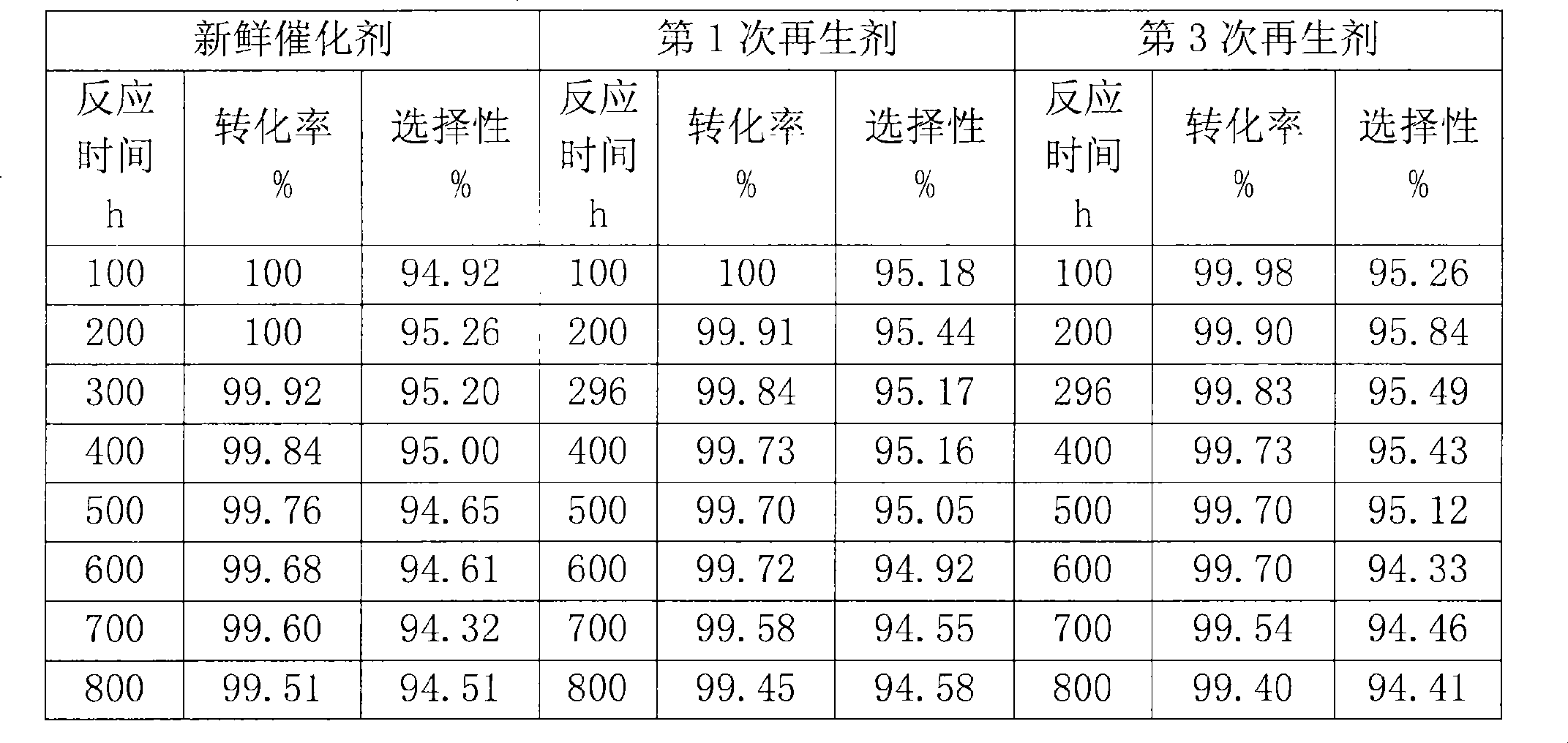

Embodiment 3

[0044] With the reaction conditions of Example 1, when the cyclohexanone oxime conversion rate dropped to 99.5%, stop adding the cyclohexanone oxime-methanol mixture, purging under the condition that the nitrogen flow rate was 6L / gcat / hr, and feed methanol simultaneously (3 g / gcat / hr), the reactor temperature was lowered to 340°C. The feed gas is then switched from nitrogen to air. The air flow rate was 8L / gcat / hr, the catalyst was heat-treated for 5 hours, and the deactivated catalyst was regenerated at a temperature of 500°C for 36 hours. The ammonia water-ammonium nitrate buffer solution with a pH value of 11.3 was circulated and injected into the catalyst bed through a pump, and treated at a reaction temperature of 80° C. for 1 hour. Stop feeding the buffer solution, wash with water for 2 hours, and dry at 120°C to obtain a regenerated rearrangement catalyst.

[0045] The air was changed to nitrogen at a flow rate of 6 L / gcat / hr until the temperature was lowered to 380° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Micropore specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com