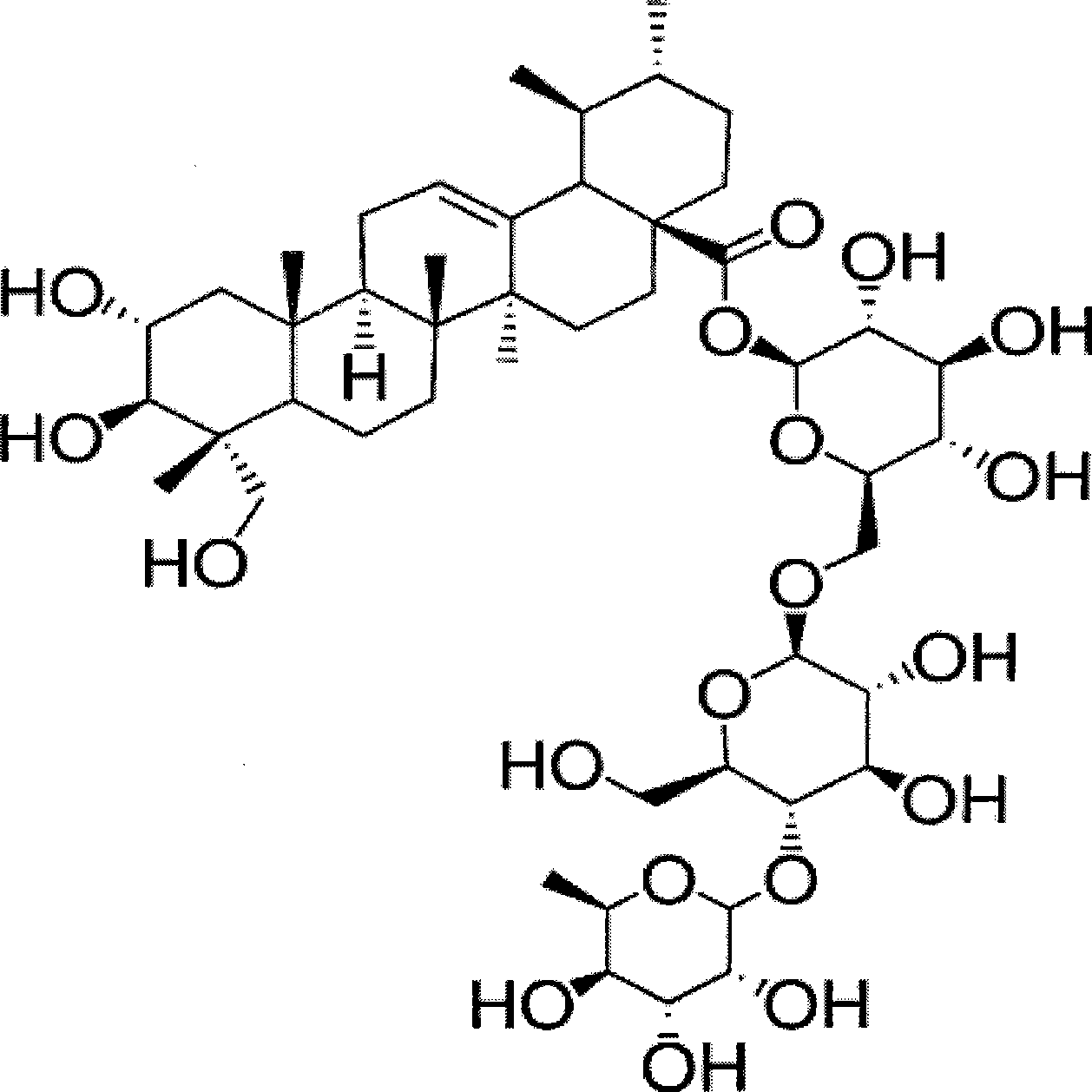

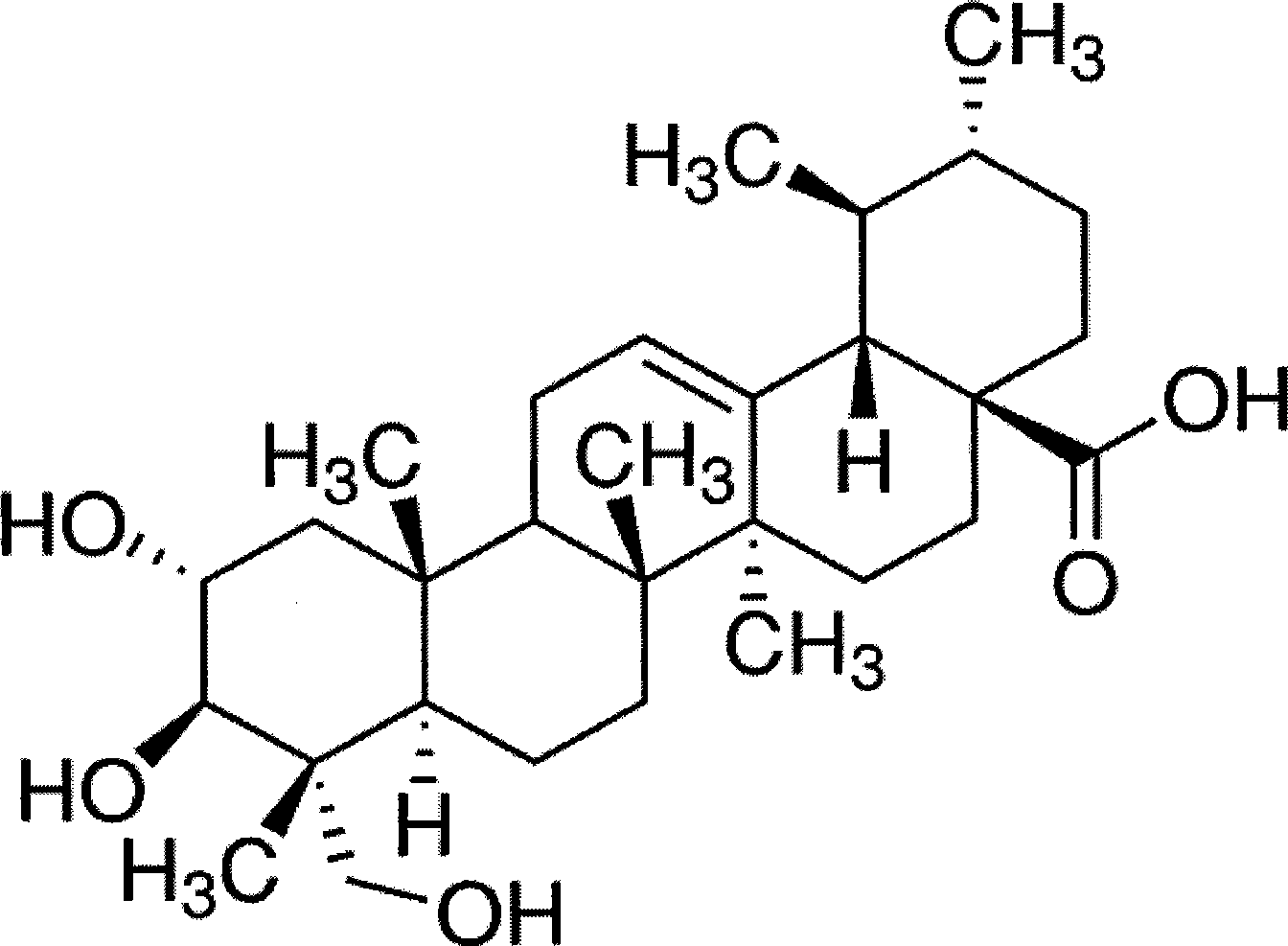

Method for producing asiatic acid with asiaticoside acid hydrolysis

A technology of asiatic acid and asiatic acid, which is applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, steroidal compounds, etc., can solve the problems of tediousness, time-consuming and labor-intensive consumption, and large solvent consumption, and achieve simple process , high yield and purity, low investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

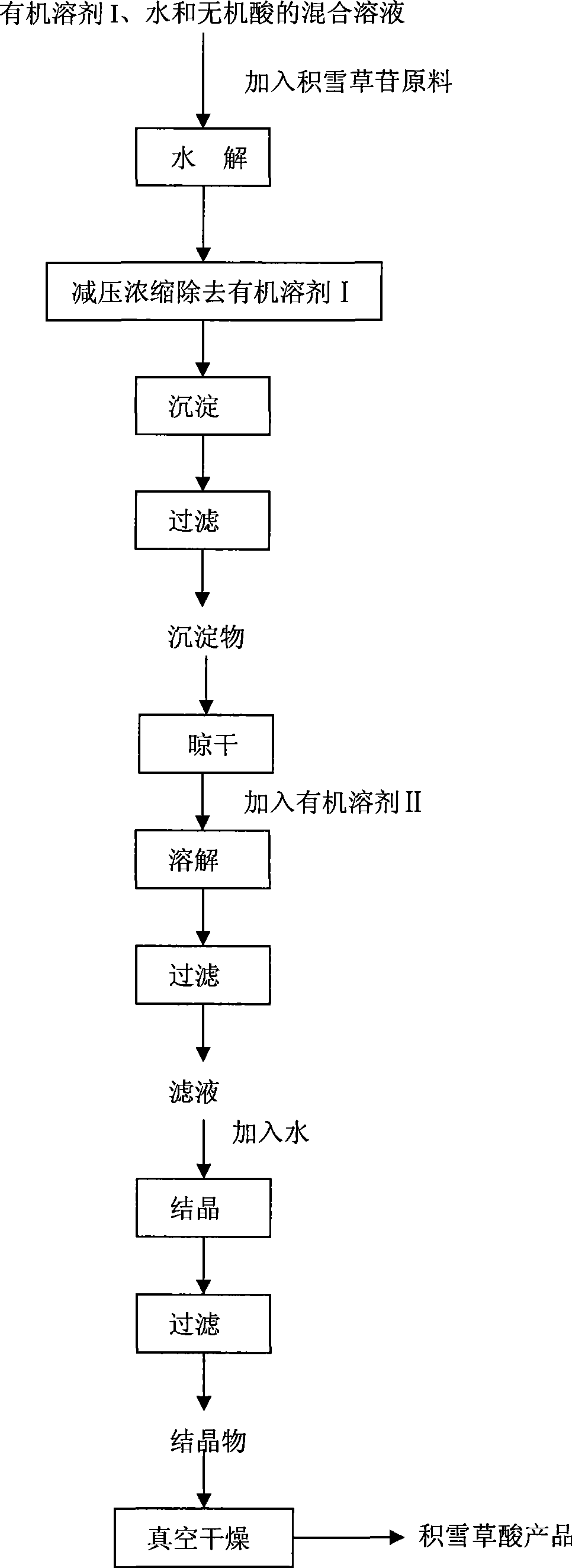

Method used

Image

Examples

Embodiment 1

[0030] Add 1000mL of a mixed solution of methanol, water and sulfuric acid to a 2L three-necked flask with a stirring and water condenser, wherein the volume percentage of methanol is 10%, and the equivalent concentration of sulfuric acid is 0.1N; the three-necked flask is placed in a constant temperature water bath at 70°C , stir and condense water, add 5g asiaticoside raw material, hydrolyze for 15h; hydrolyzate is concentrated under reduced pressure to remove methanol, precipitate and filter to obtain a precipitate, which is weighed to obtain 2.0g after drying; collect and dry The precipitate was dissolved by adding 20mL of methanol and filtered, and the filtrate was crystallized by adding 120mL of water, and the crystal was obtained after filtration, and the crystal was dried in vacuum to obtain 1.0g of Asiatic acid product, and the product was analyzed by HPLC. The mass content of Asiatic acid was 85.2%. Yield 36.8%.

Embodiment 2

[0032] Add 1000mL of a mixed solution of methanol, water and hydrochloric acid to a 2L three-necked flask with a stirring and water condenser, wherein the volume percentage of methanol is 20%, and the equivalent concentration of hydrochloric acid is 0.5N; the three-necked flask is placed in a constant temperature water bath at 65°C , start stirring and condensing water, add 6g of asiaticoside raw material, hydrolyze for 10h; hydrolyzate is concentrated under reduced pressure to remove methanol, precipitate and filter to obtain a precipitate, which is weighed to obtain 2.5g after drying; collect and dry The precipitate was dissolved by adding 50mL of ethanol, filtered, and the filtrate was crystallized by adding 350mL of water, and the crystal was obtained after filtration, and the crystal was dried in vacuum to obtain 1.6g of Asiatic acid product, and the product was analyzed by HPLC. The mass content of Asiatic acid was 90.1%. Yield 51.8%.

Embodiment 3

[0034] Add 1000mL of methanol, water and sulfuric acid mixed solution into a 2L three-necked flask with stirring and water condenser, wherein the volume percentage of methanol is 30%, and the equivalent concentration of sulfuric acid is 1N; the three-necked flask is placed in a constant temperature water bath at 60°C, Turn on stirring and condensing water, add 8g of asiaticoside raw material, and hydrolyze for 8 hours; the hydrolyzate is concentrated under reduced pressure to remove methanol, precipitated and filtered to obtain a precipitate, which is weighed after drying to obtain 3.6g; collect the dried precipitate Add 108mL of methanol to dissolve the product, filter, add 864mL of water to the filtrate to crystallize, obtain crystals after filtration, and then vacuum dry the crystals to obtain 2.2g asiatic acid product, the product is analyzed by HPLC. The mass content of asiatic acid is 91.4%. The rate is 54.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com