Neutralization-free furfural wastewater biochemical treatment process

A technology for biochemical treatment and waste water, applied in natural water treatment, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc. High operating costs and other issues, to achieve the effect of improved treatment effect, strong decomposition ability, saving equipment and pool body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

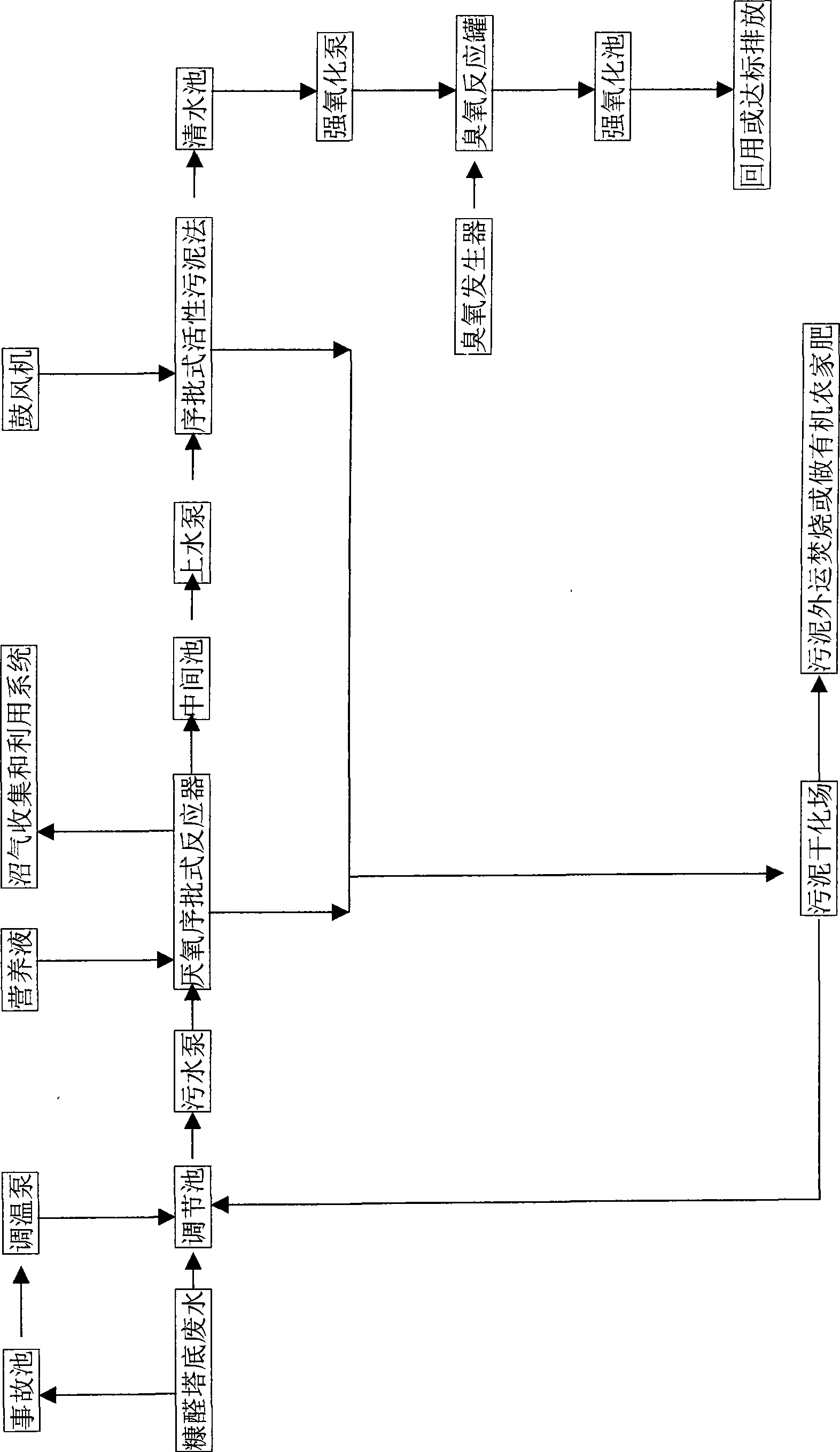

Method used

Image

Examples

Embodiment Construction

[0027] Furfural wastewater first enters the accident pool, and the volume of the accident pool must be able to store 10 days of waste water; after 6-7 days of waste water is stored in the accident pool, part of the high-temperature furfural wastewater generated by furfural production every day enters the regulating pool, and the rest enters the accident pool , and then use the temperature-regulating pump to pump the water from the accident pool into the regulating pool, so that the temperature of the wastewater in the regulating pool is adjusted to between 35-40°C;

[0028] Wastewater with a suitable temperature enters the anaerobic sequencing batch reactor under the lift of the sewage pump. The anaerobic sequencing batch reactor must maintain a bicarbonate alkalinity of 1500-2500mg / L and a temperature of 35-40°C, and pass Add the special nutrient solution for furfural wastewater to maintain the necessary nutrients for anaerobic bacteria. The bicarbonate alkalinity is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com