Health product oral fast-release preparation and production method thereof

A technology for immediate-release preparations and manufacturing methods, applied in food preparation, application, food science and other directions, can solve the problems of low tablet strength, limited dosage of main drugs, large dosage of auxiliary materials, etc., and achieves improved dispersion rate and raw material adaptability. Wide and large drug loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0140] Embodiment 1: the manufacture of pear paste preparation

[0141] (1) Prepare ingredients: main ingredients (take 38 parts of Liqing Gao, 6 parts of Chuan Fritillaria, 10 parts of Ophiopogon japonicus, 3 parts of Lily, and 3 parts of Coltsfoot Flower. Add 7 times the amount of water to the medicinal materials except Li Qing Gao, fry Boil and extract 2 times, each time for 1 hour, combine the two extracts, filter, add pear clear paste to concentrate to a relative density of 1.05-1.10, add 10 parts of dextrin and mix well, and spray dry to powder) 200kg, excipients (xylitol 300kg, refined vegetable oil 200kg, lecithin 10kg)

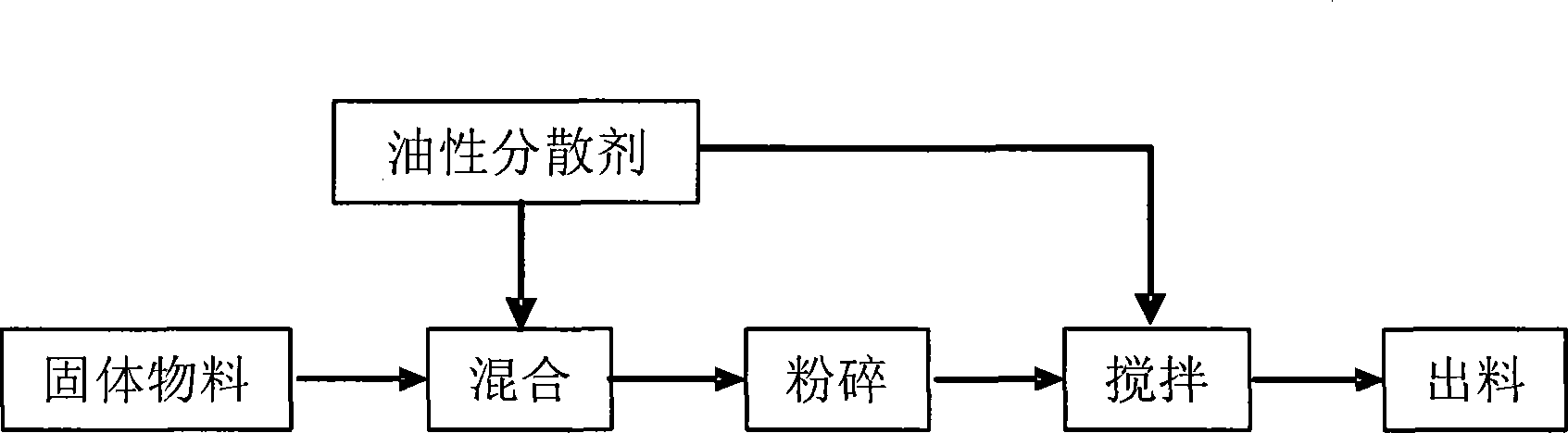

[0142] (2) Slurry preparation: refinement first - using semi-dry method, roller grinding method (see Image 6 ). Specifically: add 200kg of main ingredients to 300kg of xylitol powder (60-120 mesh) and 130kg of refined vegetable oil (39-62°C), mix them, and grind them in a five-roll mill (or three-roll mill) to 22-30 microns. Then liquefy—put the m...

Embodiment 2

[0144] Embodiment 2: the manufacture of snow clam Cordyceps preparation

[0145] (1) Material preparation: main ingredients (100 parts of snow clam, 3 parts of Cordyceps mycelium) 160kg, auxiliary materials (30kg of isomaltose, 100kg of isomalt, 100kg of refined palm oil, 2kg of lecithin)

[0146] (2) Slurry preparation: refinement first - using semi-dry method, roller grinding method (see Image 6 ). Specifically: mix 160kg of main ingredients with 30kg of isomaltooligosaccharide, 100kg of isomalt and 80kg of refined palm oil (37-48°C), and pre-grind in a two-roll mill (or three-roll mill) to 70-160 microns , and then enter the five-roll mill (or three-roll mill) for grinding to 16-28 microns. Then liquefy—put the material into a refiner (blender) for refining (stirring) for 5 to 7 hours, during which lecithin and the remaining refined palm oil are gradually added according to the viscosity of the material.

[0147] (3) Molding: After refining (stirring), discharge the mat...

Embodiment 3

[0148] Embodiment 3: the manufacture of acid enzyme preparation

[0149] (1) Material preparation: main ingredients 200kg (100 parts of black plum, 100 parts of hawthorn, 10 parts of licorice, 7 parts of sweet-scented osmanthus. Add 7 times the amount of the above materials, boil and extract twice, each time for 1 hour, combine the two extractions Liquid, filtered, concentrated to a relative density of 1.05-1.10, then added 30 parts each of dextrin and lactose, mixed evenly, and spray-dried into powder), auxiliary materials (sugar 700kg, refined coconut oil 480kg, lecithin 20kg)

[0150] (2) Slurry preparation: refinement and liquefaction at the same time - using wet method and fine grinding method (see Figure 7 ). Specifically: Add 390kg of refined coconut oil (36-60°C), 700kg of powdered sugar and main ingredients to a scraper-type refiner and grind until they reach 22-26 microns, then add the remaining refined coconut oil and lecithin until uniform.

[0151] (3) Molding:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com