Efficient preparation method of sulfonated polyethersulfone monomer

A technology for sulfonated polyethersulfone and monomers, which is applied in the field of nanofiltration membrane water treatment and fuel cell application materials, reverse osmosis, and can solve the problems of low product yield, high acid content, low utilization rate, etc., and achieve improvement Utilization rate, pollution reduction, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

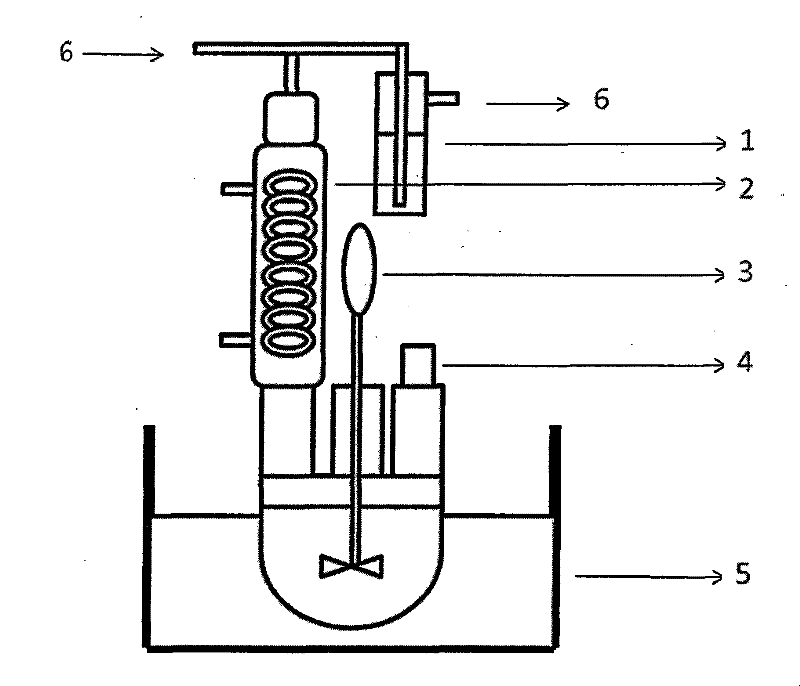

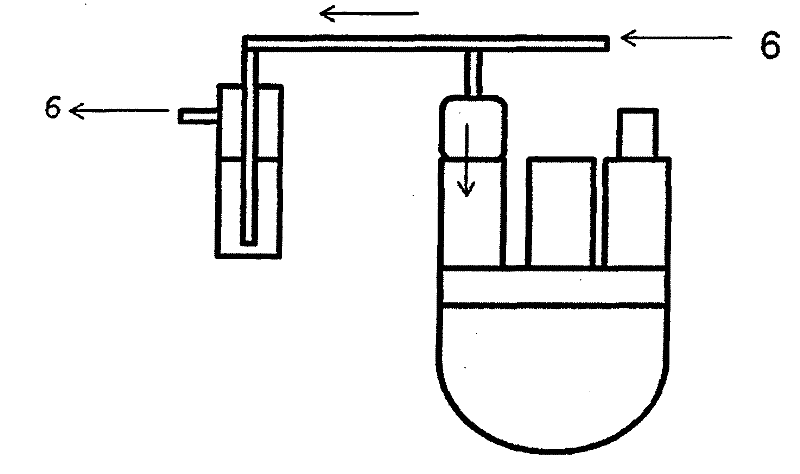

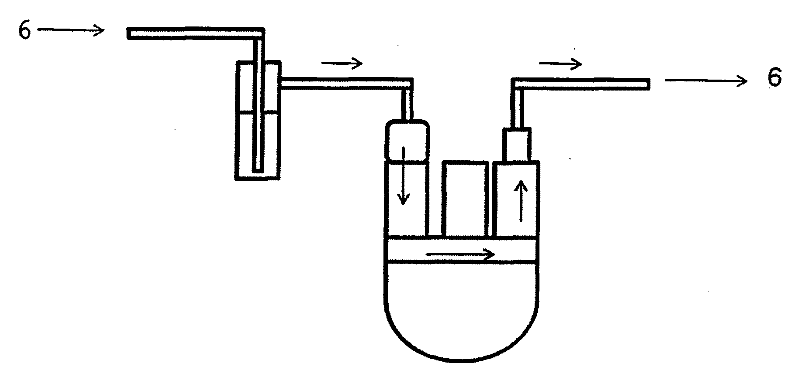

[0021] A high-efficiency preparation method for sulfonated polyethersulfone monomer is characterized in that the implementation steps include:

[0022] Dihalogenated diphenyl sulfone and oleum are used as starting materials, the fuming sulfuric acid adopts oleum with a weight concentration of sulfur trioxide of 15-25%, and the starting material is 4,4'-dihalodiphenyl sulfone The molar ratio to sulfur trioxide ranges from 1:2.00-1:1.35; the reaction temperature is 100°C-150°C, and the reaction time is 6-12 hours; the experimental device adopts a liquid-sealed type that avoids the loss of sulfur trioxide with nitrogen. Nitrogen protection system; low-temperature coolant cooling system, coolant temperature range -5°C-15°C; efficient preparation of 4,4'-dihalo-3,3'-disulfonic acid and salt diphenyl sulfone monomer.

[0023]

[0024] The above is the structure of 4,4'-dihalo-3,3'-disulfonic acid and salt diphenyl sulfone monomer (X=F or Cl; M=H, the first group of alkali metals,...

Embodiment 1

[0033] Get 133 grams of 4,4'-dichlorodiphenyl sulfone and 500 grams of sulfur trioxide weight concentration of 20% fuming sulfuric acid to mix, adopt liquid-sealed nitrogen system protection, under the cooling condition of 5 ℃ ethanol circulating cooling liquid, be heated to React at 130°C for 7 hours, cool naturally to room temperature, and pour into 1.2 liters of ice water. Add 100 g of sodium chloride, stir at room temperature for 4 hours, filter, and drain the solid. Repeat the above operation of adding sodium chloride twice; combine the obtained white solids, add 1 liter of water to dissolve, and adjust the pH value to 7 with 1 mole per liter of sodium hydroxide solution. Add 100 g of sodium chloride, stir at room temperature for 4 hours, filter, and drain the solid. The operation of adding sodium chloride was repeated twice, the solids were combined and dried to obtain 223 grams of white solid product with a yield of 98%.

Embodiment 2

[0035] Get 133 grams of 4,4'-dichlorodiphenyl sulfone and 400 grams of sulfur trioxide weight concentration to be 25% oleum and mix, adopt the protection of liquid-sealed nitrogen system, under the cooling condition of 12 ℃ of ethanol circulation coolants, be heated to React at 150°C for 7 hours, cool naturally to room temperature, and pour into 1.2 liters of ice water. Add 100 g of sodium chloride, stir at room temperature for 4 hours, filter, and drain the solid. Repeat the above operation of adding sodium chloride twice; combine the obtained white solids, add 1 liter of water to dissolve, and adjust the pH value to 7 with 1 mole per liter of sodium hydroxide solution. Add 100 g of sodium chloride, stir at room temperature for 4 hours, filter, and drain the solid. The operation of adding sodium chloride was repeated twice, the solids were combined and dried to obtain 218 grams of white solid product with a yield of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com