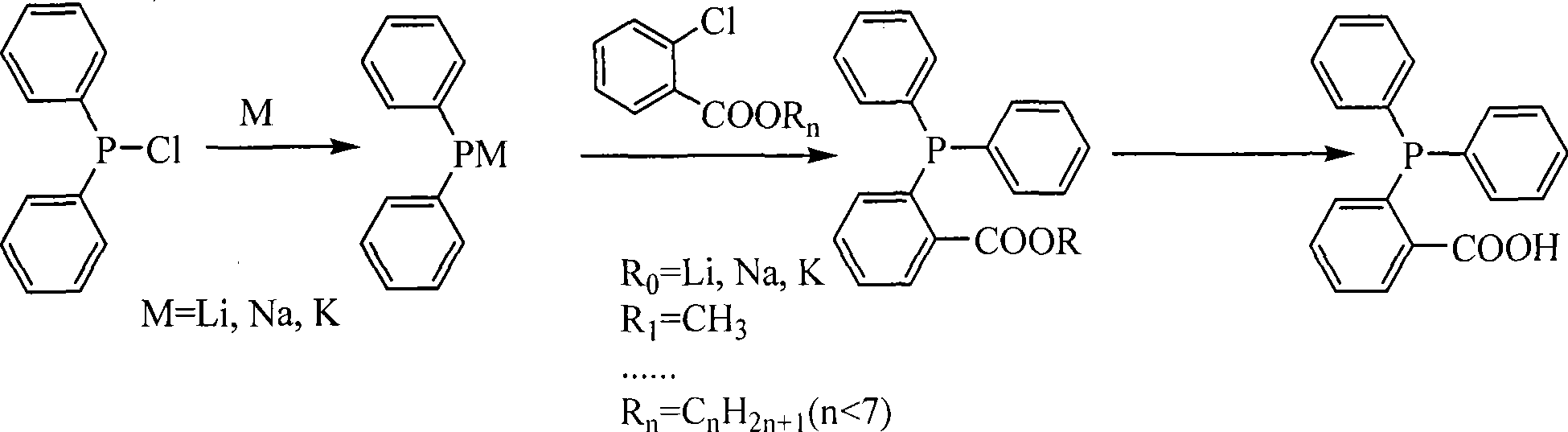

Process for synthesizing O-diphenylphosphinolbenzoic acid

The technology of a diphenylphosphine and a synthesis method is applied in the synthesis field of O-diphenylphosphine benzoic acid, can solve the problems of liquid ammonia environmental pollution, high product cost, many impurities, etc., and achieves simple technological process, convenient operation, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

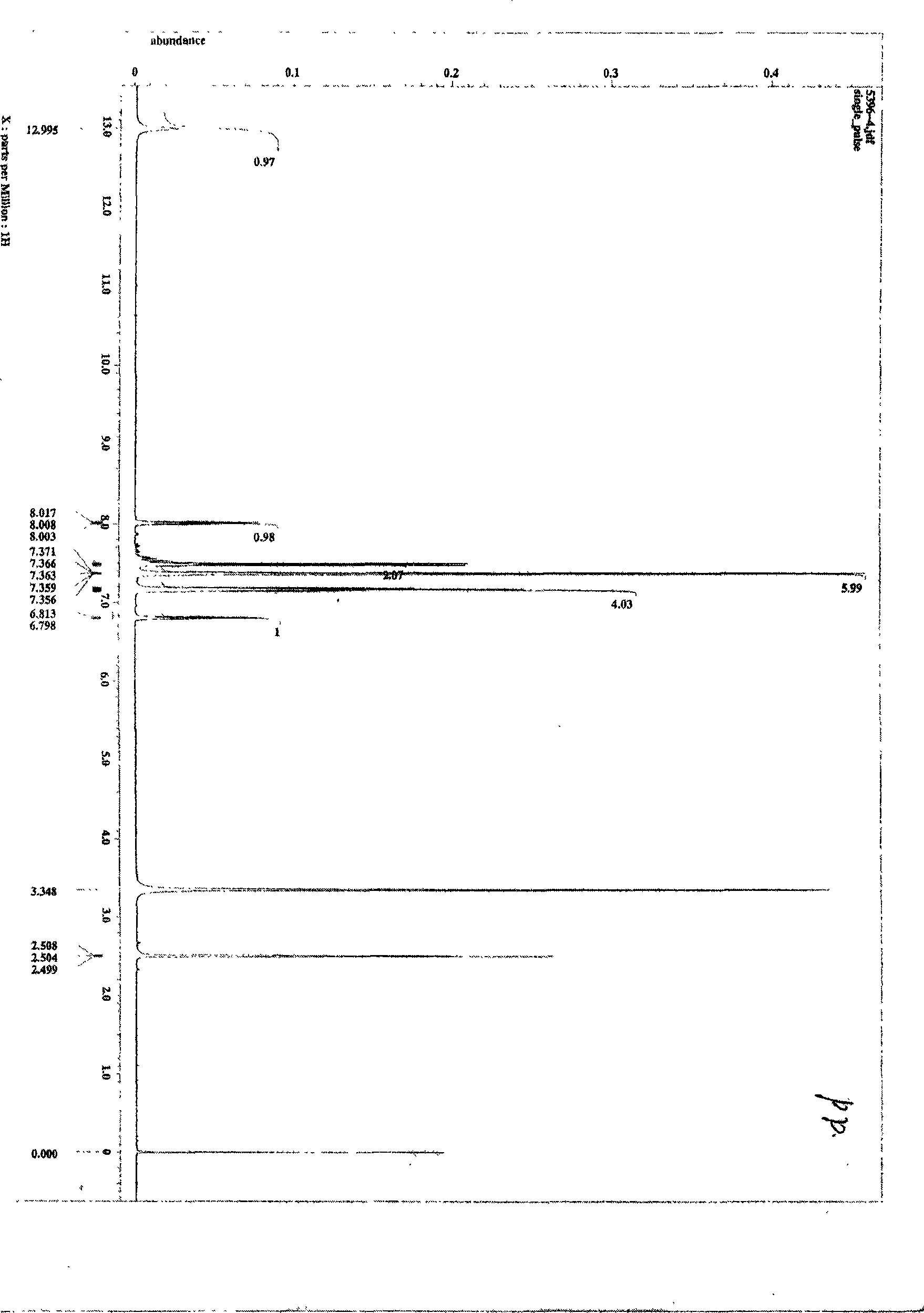

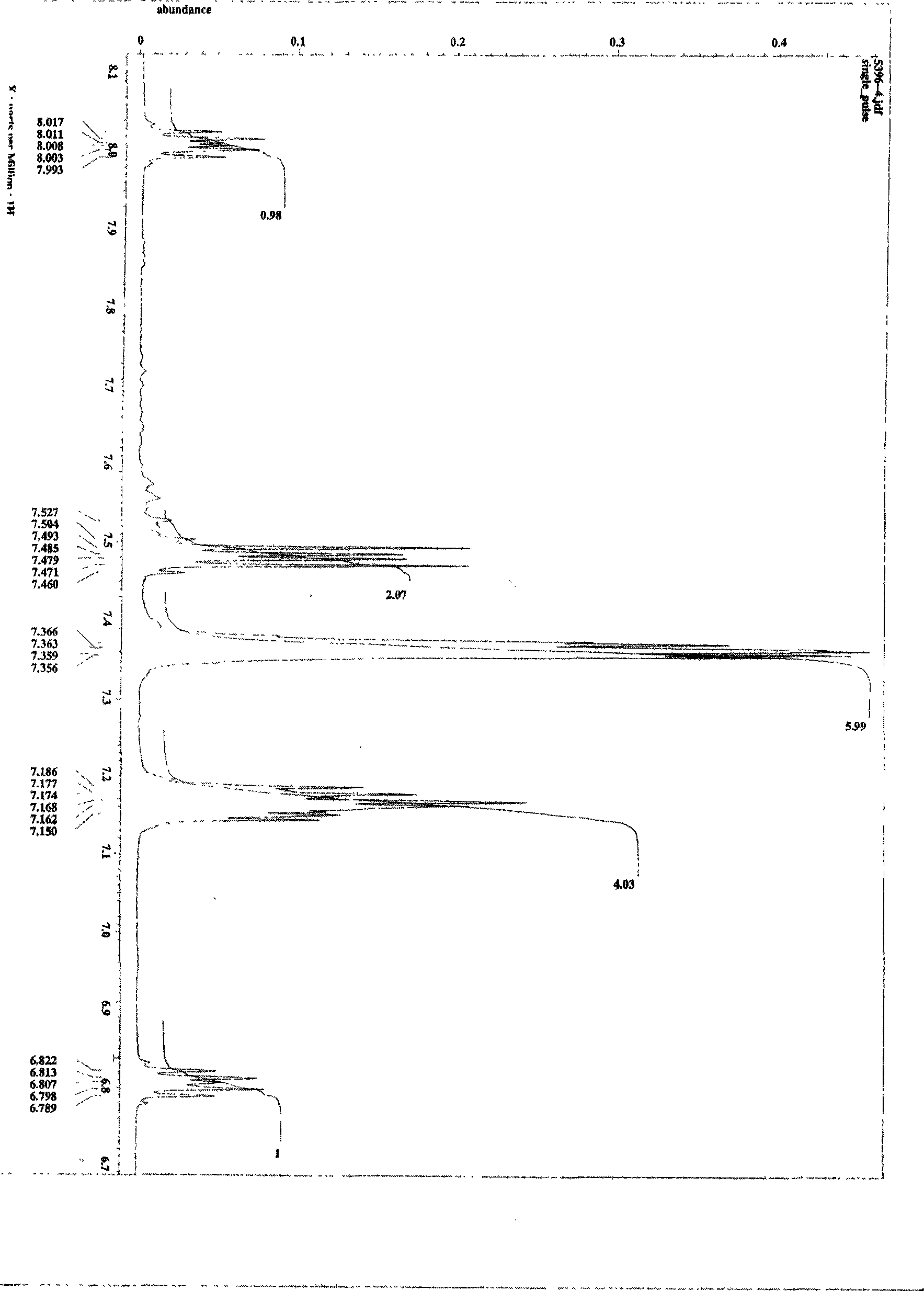

Embodiment 1

[0030] Add 50ml tetrahydrofuran, 1.0g sodium metal, and 4.4g diphenylphosphine chloride into a 250ml three-necked flask, and react at 20°C for 15 hours to completely react diphenylphosphine chloride to form sodium diphenylphosphine, and lower the temperature to 0°C , add 3.1g of methyl o-chlorobenzoate, react for 4h to generate methyl diphenylphosphinebenzoate, add concentrated hydrochloric acid for hydrolysis, concentrate to obtain 3.1g of O-diphenylphosphinebenzoate, HPLC=99.1%, yield 50.9 %.

Embodiment 2

[0032] Add 50ml of tetrahydrofuran, 1.1g of sodium metal, and 4.4g of diphenylphosphine chloride into a 250ml three-necked flask, and react at 35°C for 2.5 hours to complete the reaction of diphenylphosphine chloride to form sodium diphenylphosphine, and lower the temperature to 0 ℃, added to 100ml tetrahydrofuran system containing 6.3g of lithium o-chlorobenzoate, reacted for 3h to generate lithium diphenylphosphinebenzoate, added concentrated hydrochloric acid for hydrolysis, concentrated to obtain 3.1g of O-diphenylphosphinebenzoate, HPLC=98.9 %, yield 50.5%.

Embodiment 3

[0034] Add 65ml tetrahydrofuran, 1.1g metal sodium, 4.4g diphenylphosphine chloride to a 250ml three-necked flask, and react at 35°C for 2.5 hours to complete the reaction of diphenylphosphine chloride to form sodium diphenylphosphine, and lower the temperature to 0 ℃, add it into 100ml tetrahydrofuran system containing 7.6g sodium o-chlorobenzoate, react for 3h to generate sodium diphenylphosphinebenzoate, add dilute sulfuric acid (5%-30%) for hydrolysis, and concentrate to obtain O-diphenylphosphinebenzoic acid 3.2g, HPLC=98.5%, yield 52.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com