Separation purification process for main catechin component in tea polyphenol and glycosidase activity

A technology for separation and purification of tea polyphenols, which is applied in the direction of organic active ingredients, medical preparations containing active ingredients, organic chemistry, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 300 grams of a tea polyphenol extract with an epigallocatechin gallate content of 50%, and add 1200 mL of deionized water to dissolve it. Take 4kg of HPD100 macroporous adsorption resin and put it into the column with 95% ethanol, wash away the porogen and polymerized monomer residue in the resin with 8L of 95% ethanol, until the eluate is concentrated and qualified by gas phase detection. Then replace the ethanol in the column with deionized water, and load the above-mentioned tea polyphenol aqueous solution at a flow rate of 0.4 times the column volume / hour. Elution at flow rate per hour, and then elution with 4 times column volume of 20% ethanol, according to the detection results of silica gel thin layer chromatography, collect the epigallocatechin gallate flow fraction, and the epigallocatechin gallate flow fraction Concentrate under reduced pressure below 45°C to a small volume (1500mL) to obtain sample B. Sample B is placed on a 2kg polyamide (80-100 mesh) ...

Embodiment 2

[0026] Weigh 100 grams of a tea polyphenol extract with an epigallocatechin gallate content of 50%, and add 400 mL of deionized water to dissolve it. Get 1.0kg of D101 macroporous adsorption resin and pack it into the column with 95% ethanol, wash off the porogen and polymerized monomer residues in the resin with 95% ethanol until the eluent is concentrated and qualified by gas phase detection, and then use Replace the ethanol in the column with deionized water, and load the above tea polyphenol aqueous solution at a flow rate of 0.3 times the column volume / hour. After the sample enters the column, first use 3 times the column volume of deionized water to Flow rate elution, and then use 4 times column volume 40% ethanol to 0.3 times column volume / hour flow rate elution, according to the silica gel thin layer chromatography detection result, collect epigallocatechin gallate fraction, reduce at 45 ℃ Concentrate under pressure to a small volume (600mL) to obtain sample B. Sample ...

Embodiment 3

[0029] The epigallocatechin gallate, epicatechin and epigallocatechin prepared in the present invention are subjected to in vitro α-glucosidase and α-amylase inhibition tests.

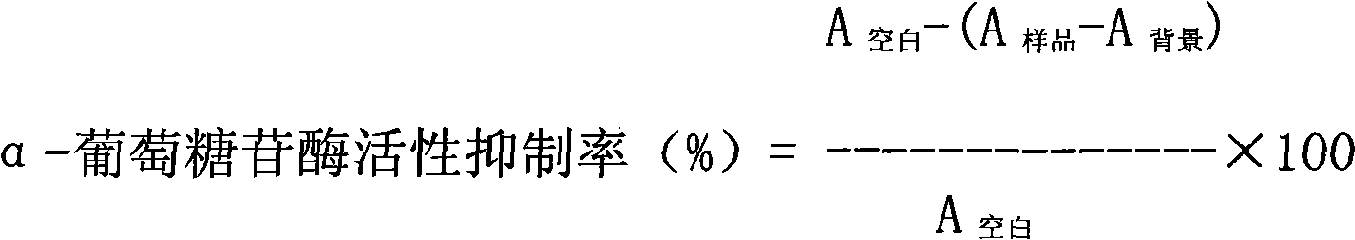

[0030] α-glucosidase activity assay

[0031] Use p-nitrophenol-α-D-glucopyranoside (4-Nitrophenylα-D-glucopyranoside, PNPG) as the substrate. The reaction system was: 67mmol / L potassium phosphate buffer (pH6.8) 2ml, 1mg / ml reduced glutathione 50μl, 0.57U / ml α-glucosidase (sigma company, Type I: fromBakers Yeast) 100μl, 37 After incubating at ℃ for 10min, add 20mmol / L PNPG 200μl, react at 37℃ for 30min, add 0.1mol / L Na 2 CO 3 Stop solution 10ml. Acarbose was used as a positive control. Absorbance was measured at 400 nm.

[0032]

[0033] In the formula:

[0034] A 空白 : Absorption value after reaction without adding sample

[0035] A 样品 : Absorption value after adding sample to react

[0036] A 背景 : Only add the absorbance value of the sample

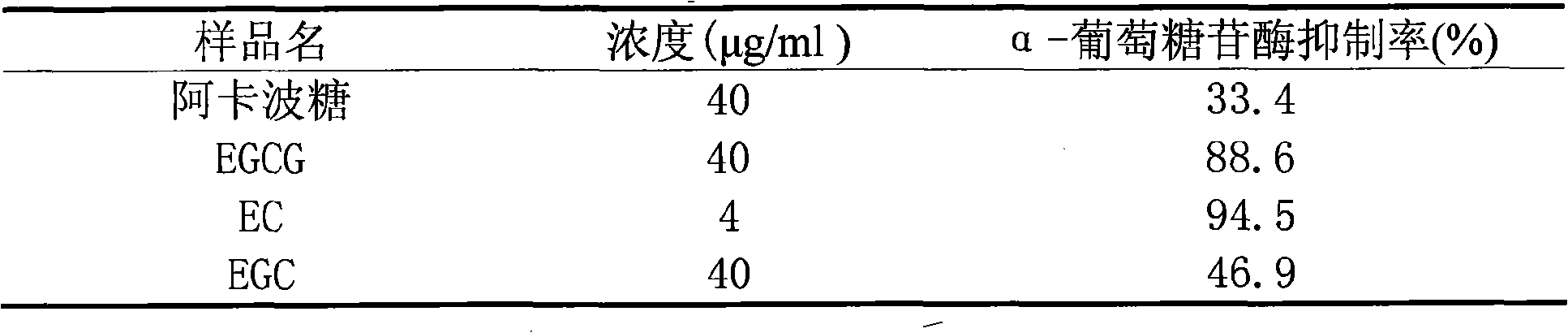

[0037] The results of α-glucosidase activity as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com