Self-air-suction vacuum plating method

A vacuum coating and self-breathing technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of not considering the activity of coating materials, the vacuum system is not universal, and the materials are not the same. , to achieve strong universality, speed up the process of vacuuming, and improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

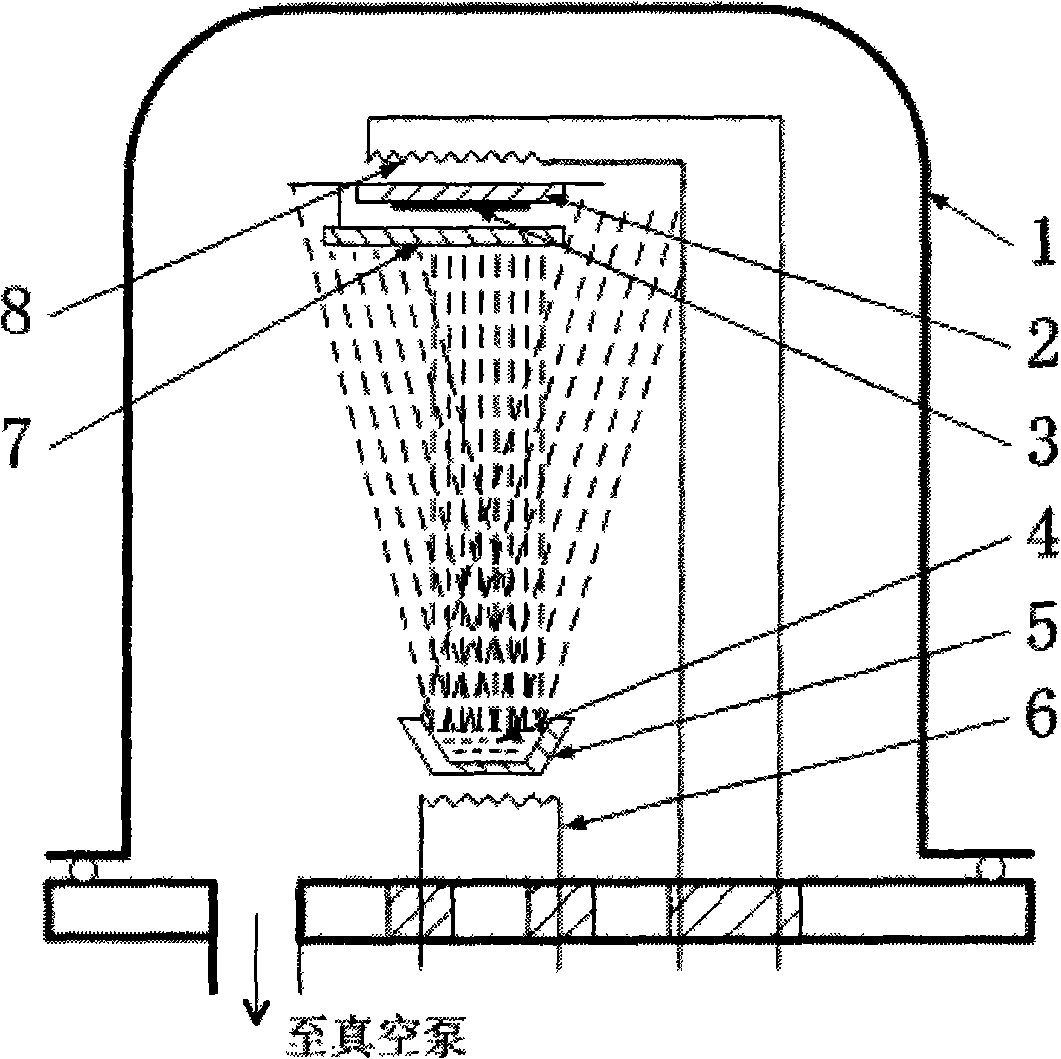

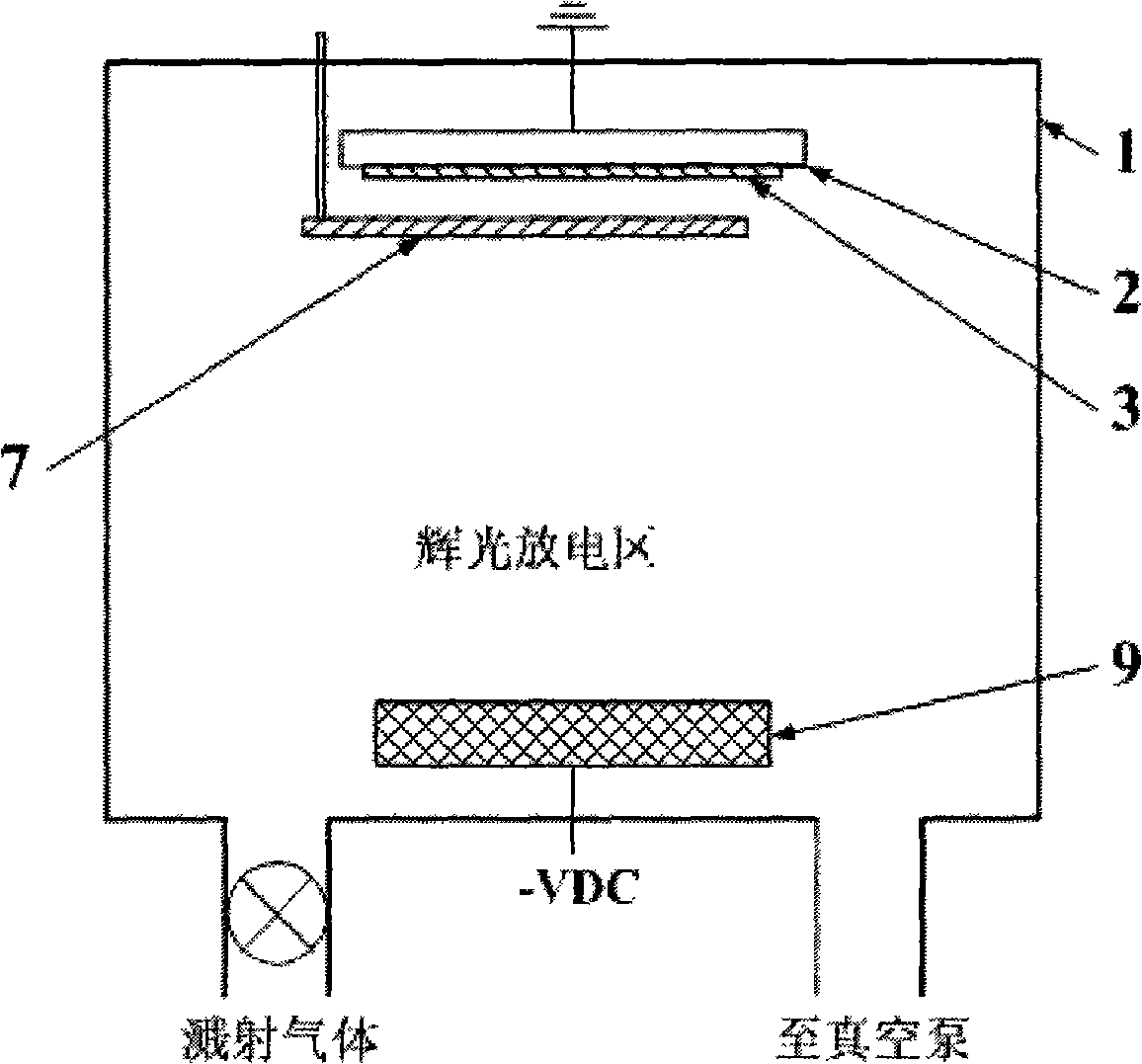

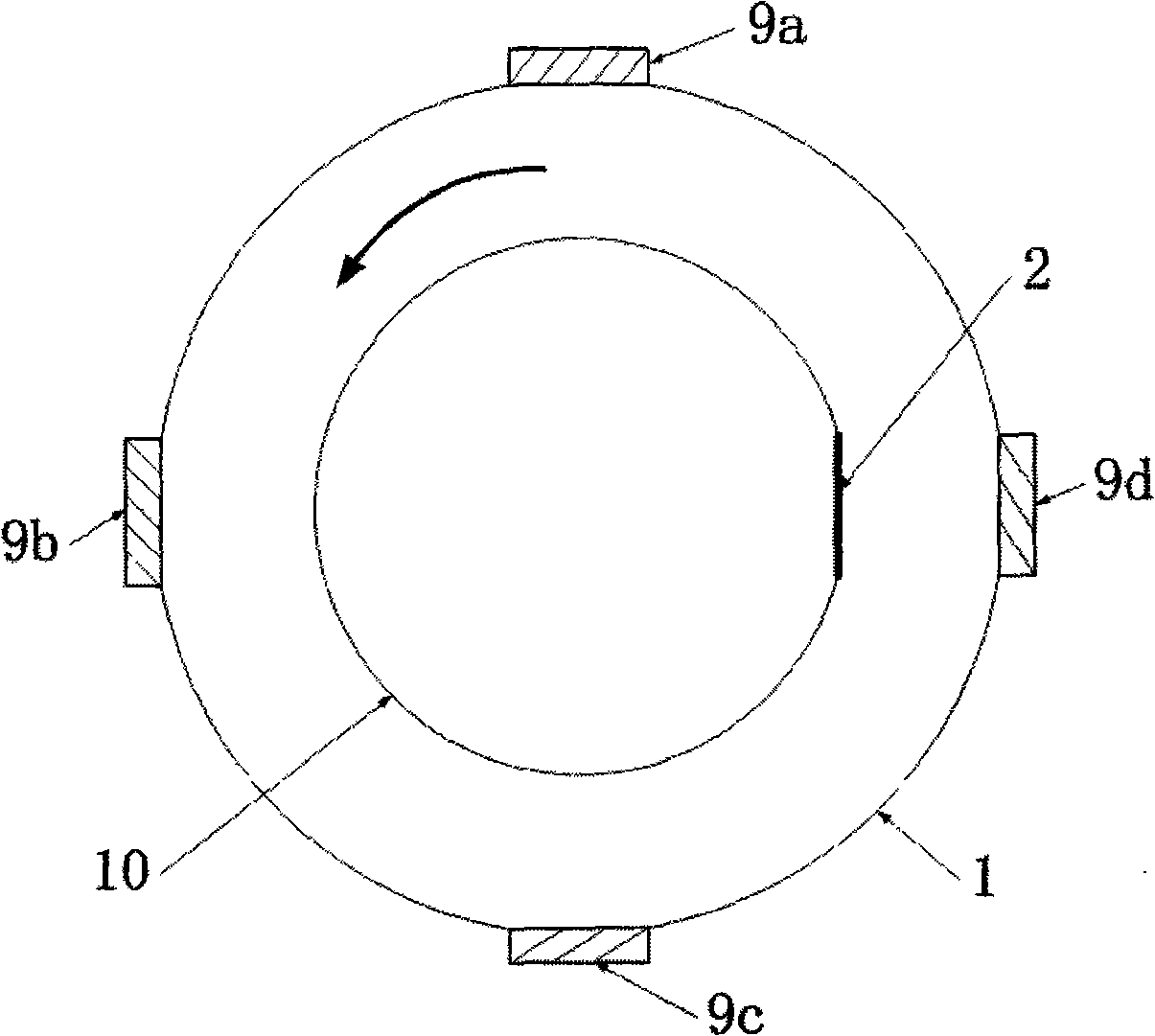

[0030] Figure 4 It is a schematic flow chart of the self-absorbing vacuum coating process of the present invention, and the operation steps shown are as follows (1) evacuate the vacuum chamber to a preset value P1; (2) pre-deposit a layer of thin film under the shielded state of the substrate; (3) ) stop the thin film deposition, continue vacuuming to the preset value P2, P2 < P1; (4) keep the substrate in an unshielded state, and formally deposit the thin film on the substrate. The method is used for evaporation coating method or sputtering coating method or ion coating method or ion beam assisted deposition method or ionization group beam coating method. Suitable for active metals or alloy films containing active metals, including magnesium, aluminum, calcium, scandium, titanium, vanadium, chromium, manganese, iron, cobalt, nickel, rubidium, stronti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com