Sitafloxacin sustained-release pellet and preparation method thereof

A technology of sitafloxacin and sustained-release pellets, which is applied in pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., to achieve the effects of reducing irritation and improving drug bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

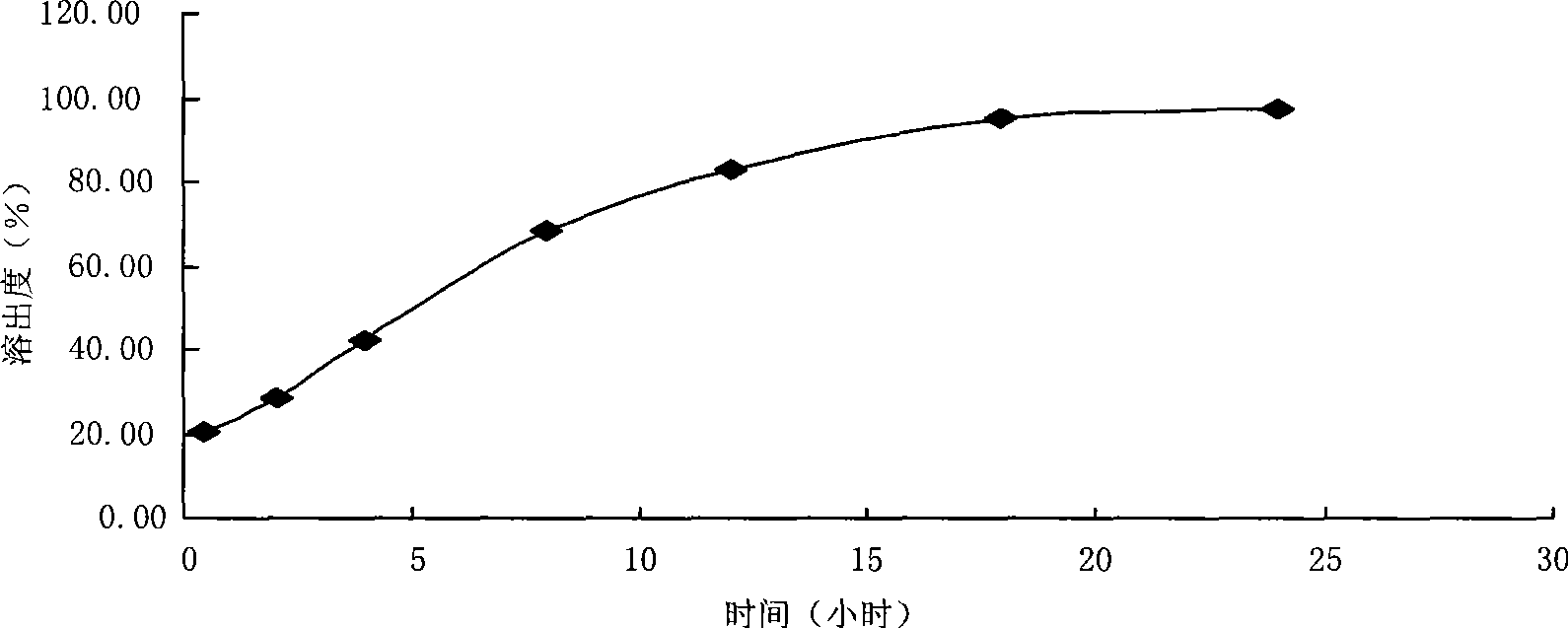

Embodiment 1

[0044] Example 1 Preparation of sitafloxacin sustained-release pellets

[0045] Raw materials: sitafloxacin, starch, dextrin, ethyl cellulose aqueous solution, povidone, diethyl phthalate, titanium dioxide and ethanol;

[0046] Preparation process: mix starch and dextrin evenly according to the weight ratio of 3:1, use 50% ethanol as wetting agent to make soft material, put the soft material in the coating pot and roll the ball core, take 20-40 mesh The core of the ball is set aside.

[0047] Put the spare blank pellet core in the fluidized bed, spray the sitafloxacin aqueous solution, and dry it. After the pellet core increases in weight to 100%, wrap an ethylcellulose film coating on the surface of the pellet to increase the weight by 5%. , to obtain sitafloxacin sustained-release pellets, and to pack the pellets into capsules to obtain sitafloxacin sustained-release pellets.

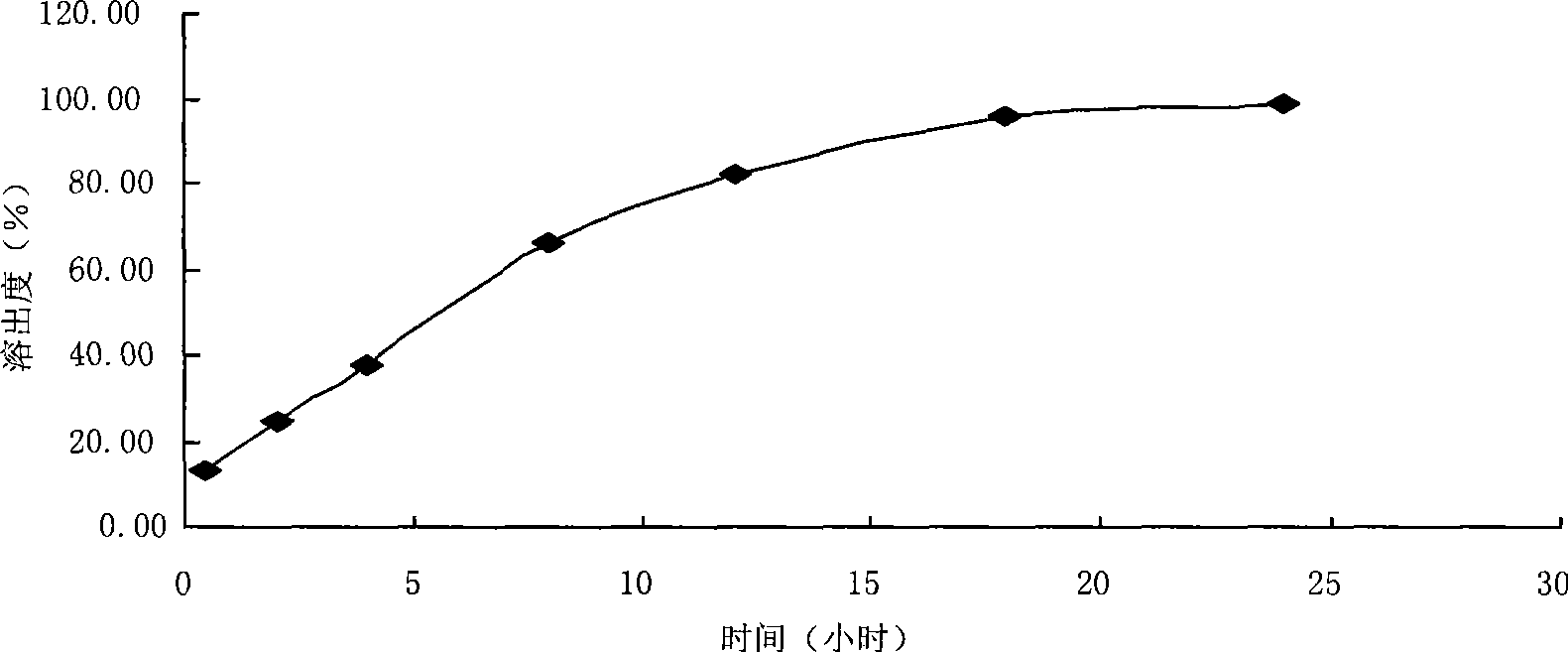

Embodiment 2

[0049] Raw materials: sitafloxacin, microcrystalline cellulose, dextrin, acrylic resin, 50% ethanol solution, polyethylene glycol 6000, castor oil, polysorbate and titanium dioxide;

[0050] Preparation process: take sitafloxacin, microcrystalline cellulose, and dextrin, mix them evenly according to the weight ratio of 7:2:1, use 50% ethanol liquid to make soft materials, extrude and granulate, and put the prepared granules into Put into the ball rolling machine and make micropills, choose the micropills between 20-30 meshes, wrap the film coating with the coating solution containing acrylic resin, make the pills increase by 5%, and obtain the sitafloxacin sustained-release micropills , the above-mentioned micropills are packed into capsules to obtain the sitafloxacin sustained-release micropill capsules.

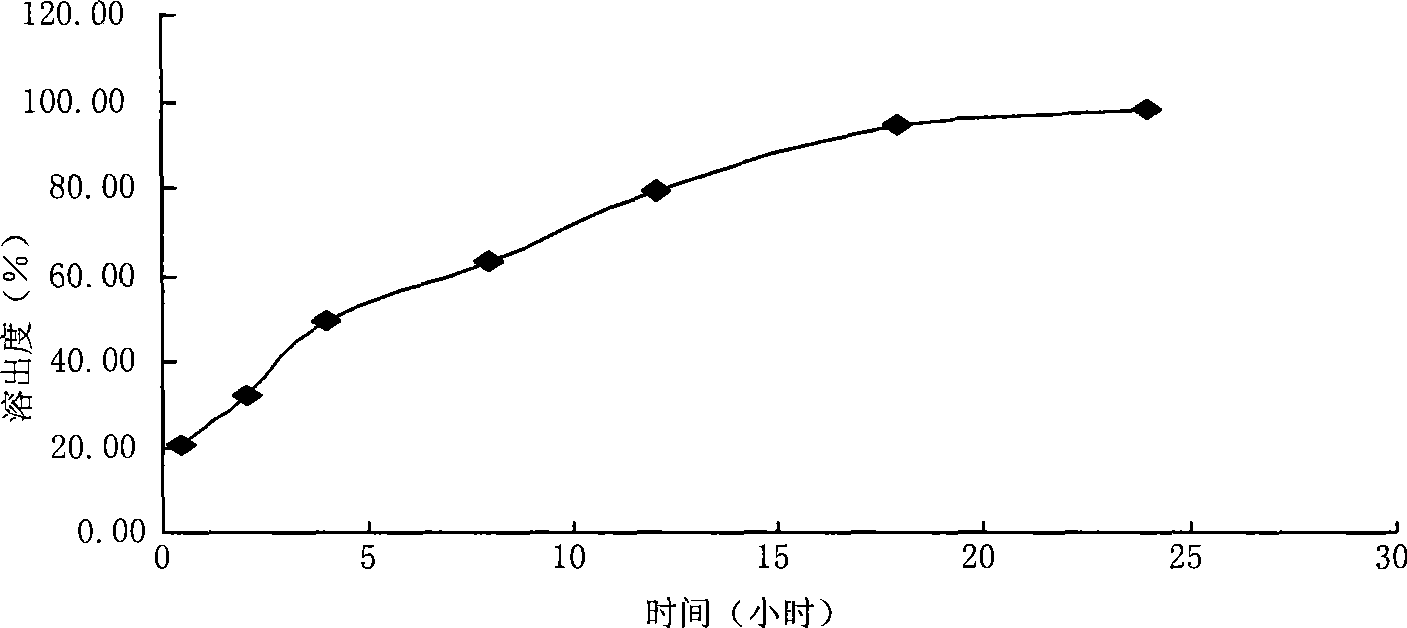

Embodiment 3

[0052] Raw materials: sitafloxacin, lactose, dextrin, 50% ethanol solution and 10% Surelease solution;

[0053] Take sitafloxacin, lactose, and dextrin, mix them evenly according to the weight ratio of 4:2:1, use 50% ethanol solution to make soft materials, and extrude the soft materials through the sieve plate of the extruder to prepare granules, and spheronize the granules Machine spheronization, screen out 14-20 mesh pellets for subsequent use, then use 10% Surelease coating solution to coat the pellets with a film coating, and increase the weight of the pellets by 7% to obtain the sitafloxacin sustained-release pellets. Take the sustained-release pellets and fill them in capsules to obtain sitafloxacin sustained-release pellets capsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com