Preparations of SAPO-11 molecular sieve and SAPO-11 molecular sieve based catalyst

A technology of SAPO-11 and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, molecular sieves and base-exchanged phosphate, etc., can solve the problems of reducing catalytic performance, not easy to repeat, and limiting isomerization of single branched chain isomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1.SAPO-11 molecular sieve synthesis

[0032] 41.5g deionized water and 14g phosphoric acid (AR, 85%, Beijing Chemical Plant) are mixed in 35 ℃ of water baths, then add 9g pseudo-boehmite (water content 27%, Changling Refinery and Chemical General Plant Catalyst Plant), Stir for 90 minutes, add a mixed solution of 5.2g propyl orthosilicate (AR, 97%, Shanghai Jingchun Reagent Co., Ltd.) and 11.7g n-propanol (AR, 99%, Shanghai Jingchun Reagent Co., Ltd.), and continue stirring After 120 minutes, slowly add 7.9 g of template agent di-n-propylamine (AR, 99%, Beijing Chemical Reagent Company), and continue stirring until a uniform colloid is formed to obtain an initial gel mixture.

[0033] The initial gel mixture was put into a stainless steel reactor with a polytetrafluoroethylene liner, crystallized at 185°C for 24 hours, and the obtained solid product was taken out, cooled, filtered, and washed with deionized water until neutral at 120°C. °C drying, and roasti...

Embodiment 2

[0036] Embodiment 2.SAPO-11 molecular sieve synthesis

[0037] Mix 65.2g of deionized water and 22.7g of phosphoric acid in a 35°C water bath, add 15g of pseudoboehmite, stir for 90 minutes, add 10.3g of orthobutyl silicate (AR, 97%, Sinopharm Group Chemical Reagent Co., Ltd. ) and 23.2g n-butanol (AR, 99%, Sinopharm Group Chemical Reagent Co., Ltd.), continue to stir for 120 minutes, then slowly add template agent di-n-propylamine 12.7g, continue to stir until forming a uniform colloid, and obtain the initial Gel mixture.

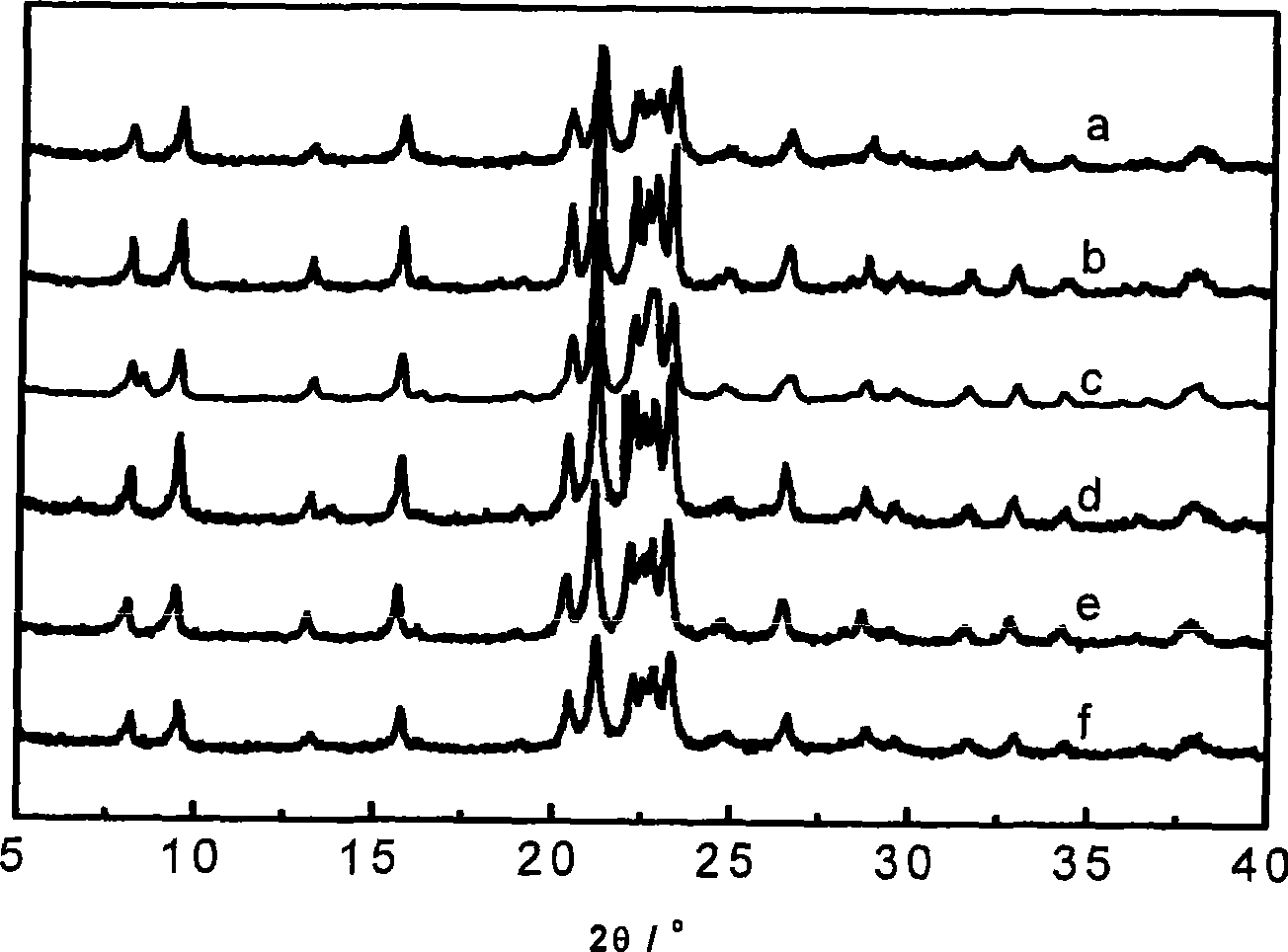

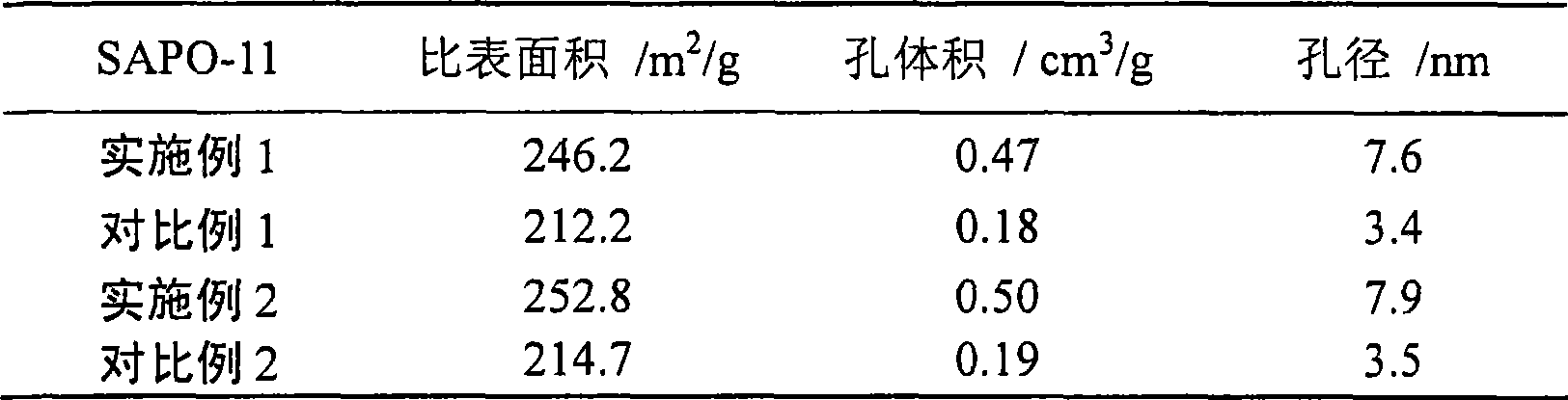

[0038] The initial gel mixture was put into a stainless steel reaction kettle with polytetrafluoroethylene lining, sealed and heated to 185°C for constant temperature crystallization for 24 hours, taken out, cooled, filtered, washed with deionized water until neutral, and then baked at 120°C dry, and calcined at 600°C for 5 hours to obtain SAPO-11 molecular sieve, whose X-ray diffraction pattern is as follows: figure 1 As shown in c, the pore structure p...

Embodiment 3

[0044] Embodiment 3.SAPO-11 molecular sieve synthesis

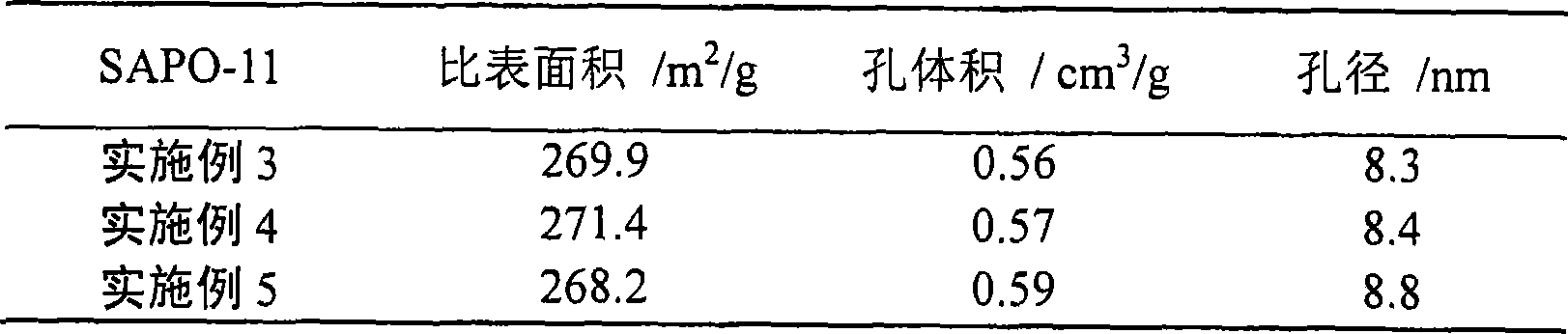

[0045] The operation of the synthetic process is the same as in Example 1, but 7.9g di-n-propylamine is changed into the mixed solution of 7.1g di-n-propylamine and 1.0g di-n-butylamine (AR, 99%, Beijing Chemical Reagent Company), all the other components and Operation is all the same, obtain SAPO-11 molecular sieve, its X-ray diffraction pattern is as follows figure 1 As shown in d, its pore structure parameters are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com