Wastewater treatment recycling technique and equipment thereof

A wastewater treatment and process technology, applied in flotation water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of huge investment and high operation and maintenance costs, which limit the feasibility and the longevity of organic membranes. It can improve the oxidation effect, low operating cost and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

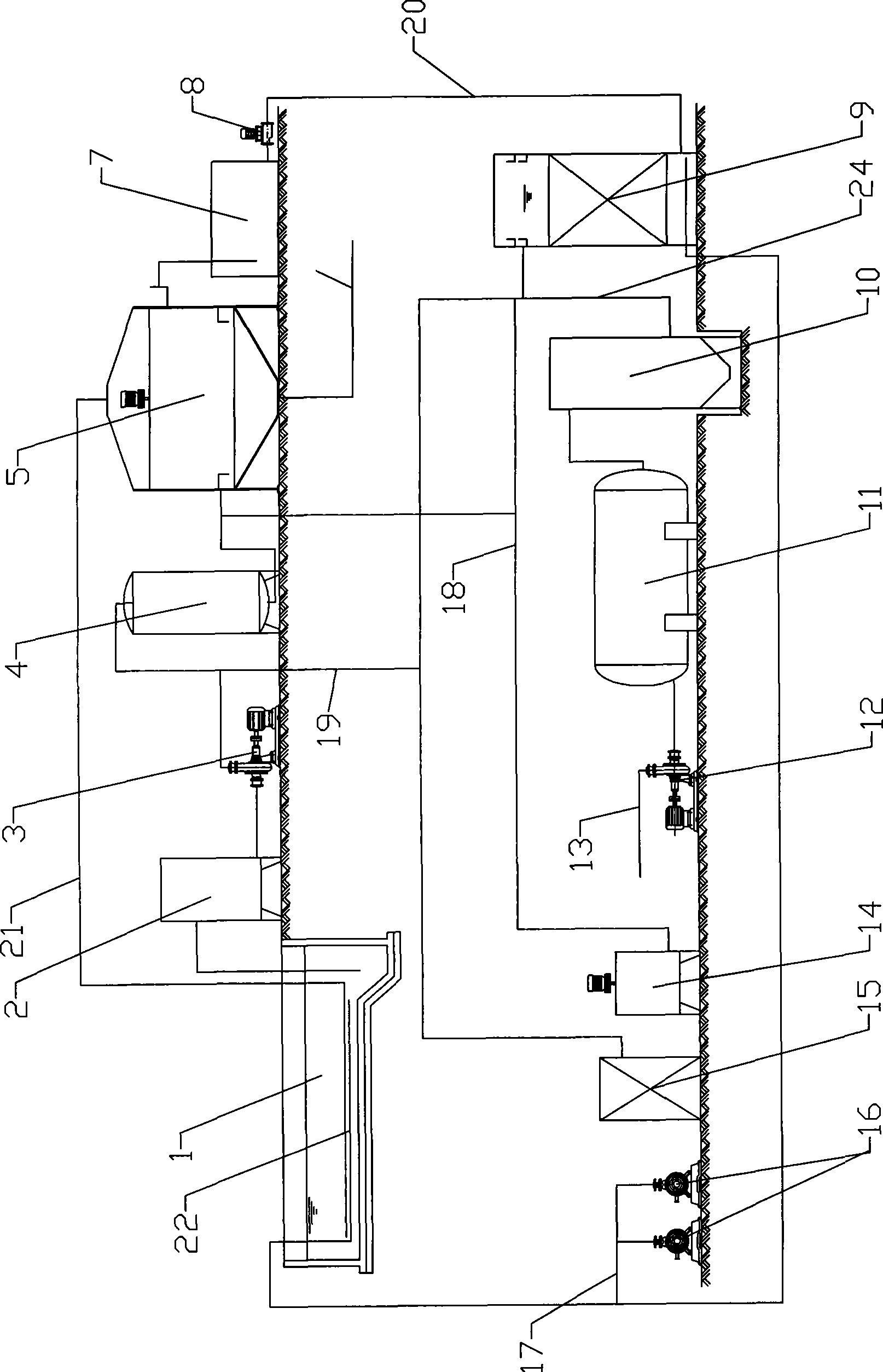

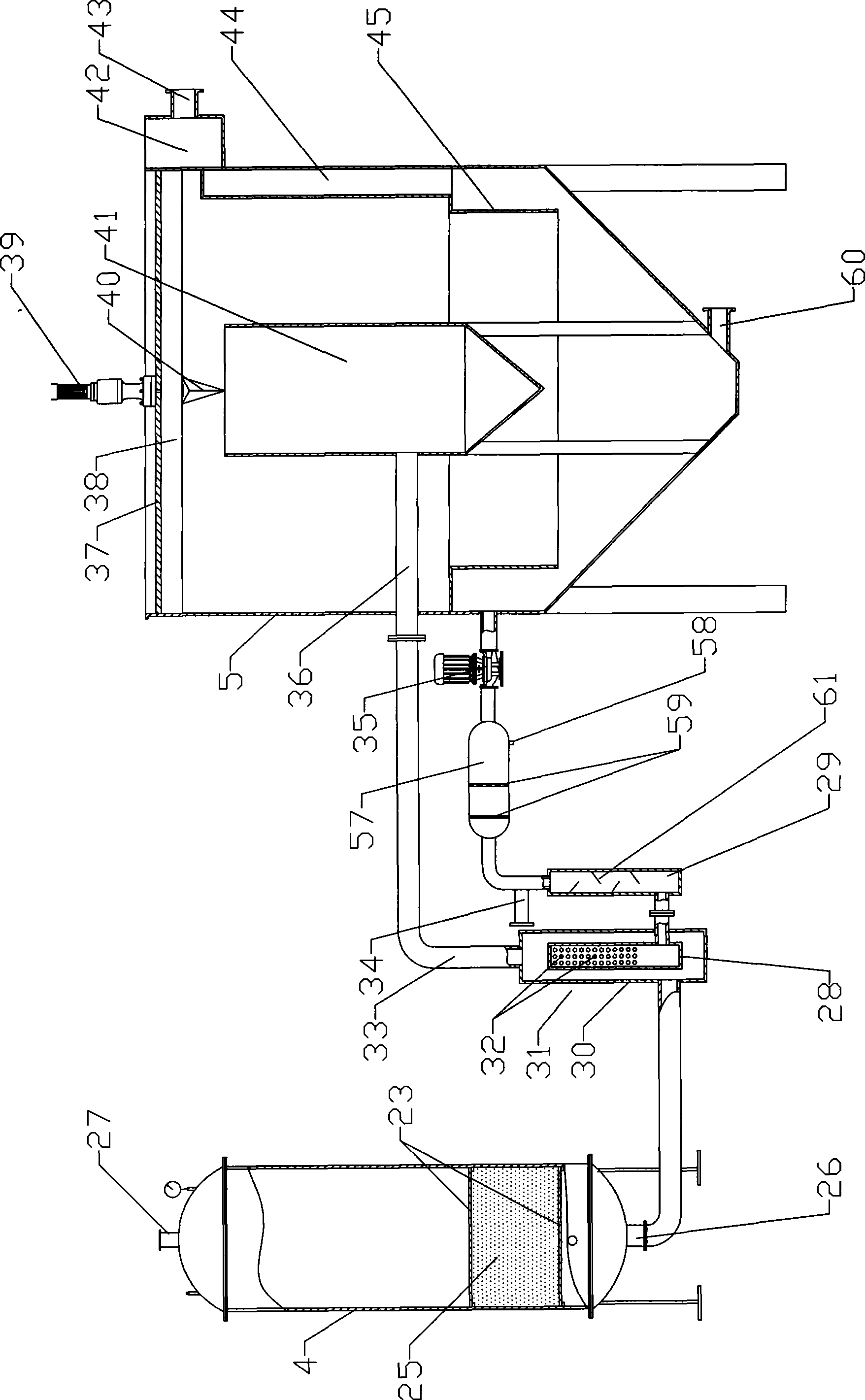

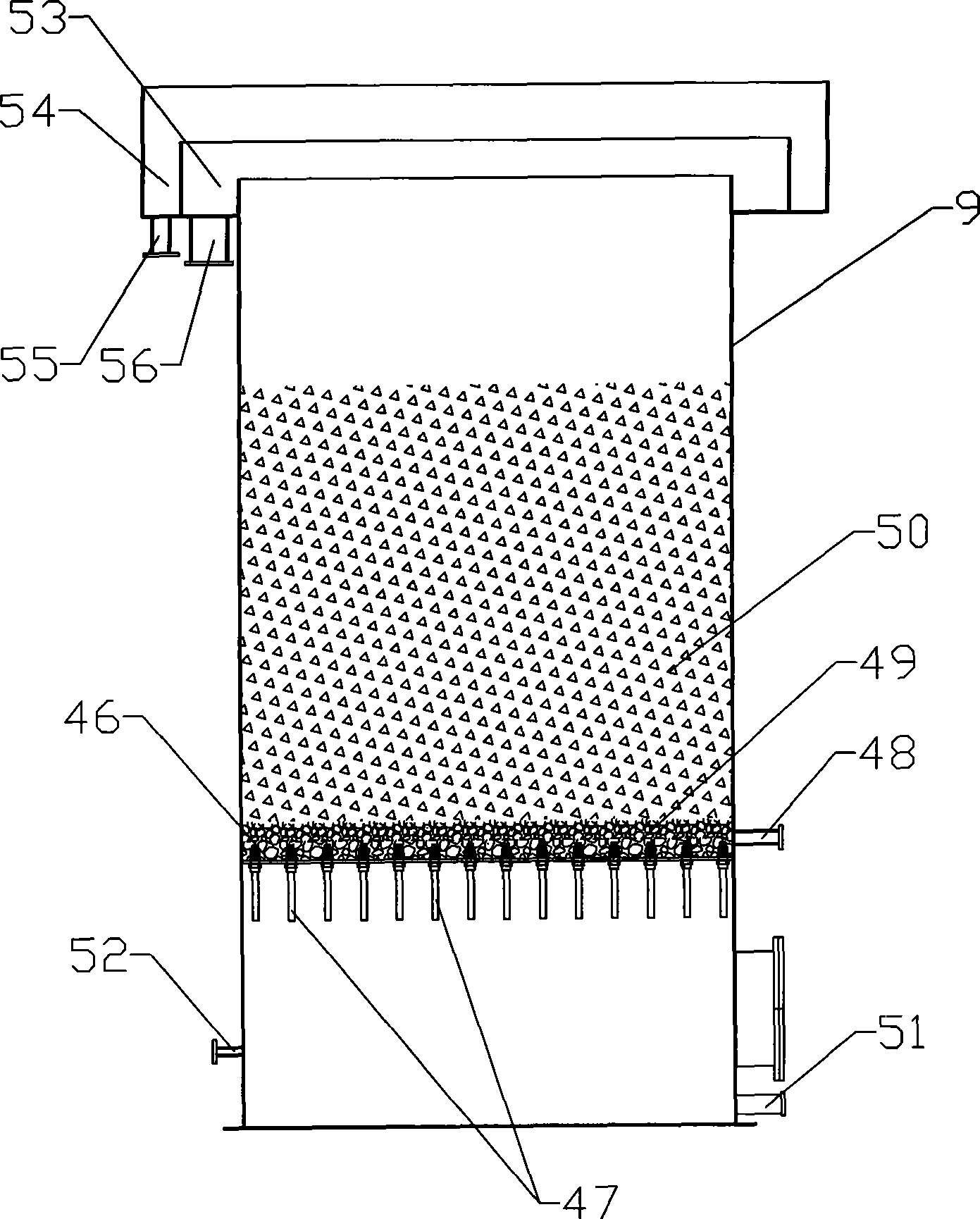

[0032] Examples such as figure 1 As shown, a wastewater treatment and reuse process and its equipment, the wastewater treatment equipment includes a regulating tank 1, a water diversion tank 2, a sewage lifting pump 3, an ozone mixing tank 4, an ozone air flotation water purifier 5, an intermediate water tank 7, and an intermediate water pump 8. BAF biological filter 9, quicksand filter 10, clean water storage tank 11, clean water supply pump 12, workshop water pipeline 13, dosing box 14, ozone generator 15, blower unit 16, air pipe 17, dosing Pipeline 18, ozone pipe 19, sewage pipe 20, exhaust pipe 21, aeration pipe 22, flower plate 23, pipeline mixer 24, catalytic filler 25, water outlet pipe 26, water inlet pipe 27, releaser inner pipe 28, mixing Device 29, releaser outer pipe 30, releaser 31, release hole 32, releaser outlet pipe 33, dosing pipe 34, intermediate pump 35, reaction chamber inlet pipe 36, reducer fixing plate 37, scraper 38, reducer 39. Mud discharge tank 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com