Method for preparing methyl phenyl ring siloxane mixture

A technology of methylphenyl cyclosiloxane and methylphenyl dialkoxysilane is applied in the field of preparation of methyl phenyl cyclosiloxane mixture, and can solve the problem of not providing methyl phenyl mixed ring body preparation methods, etc., to achieve the effects of high utilization of silicon atoms, energy saving, and saving of washing water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 521.8g of methylphenyldiethoxysilane with a purity greater than 99.8wt% and no trifunctional impurities, 5.2144g of LiOH·H 2 0 and 684g deionized water are added in the three-neck round-bottomed flask of 2000mL with mechanical stirring, temperature control sensor and packing separation column, the port on the packing separation column is connected with the distillation head, by adjusting the valve position on the distillation head discharge pipeline , the reflux ratio of the top material can be adjusted. Raise the temperature of the above-mentioned reaction mixture through an electric heating jacket, make methylphenyldiethoxysilane undergo hydrolysis and condensation reaction between 80~100°C, adjust the valve position on the discharge pipeline of the distillation head, and slowly receive the ethanol produced by the reaction- water mixture. After reacting for 6 hours, 633.5 g of ethanol-water mixture was received, and the refractive index of the overhead distillate was...

Embodiment 2

[0044]500g purity is greater than 99.8wt% and does not contain the methylphenyldiethoxysilane of trifunctionality impurity, the 208.6g alkaline aqueous solution and the 420g deionized water collected in the hydrolyzate oil-water separation process of embodiment 1 are added to In the 2000mL three-neck round bottom flask with mechanical stirring, temperature control sensor and packing separation column, the upper port of the packing separation column is connected to the distillation head, and the reflux ratio of the top material can be adjusted by adjusting the valve position on the discharge pipeline of the distillation head. Raise the temperature of the above-mentioned reaction mixture through an electric heating jacket, make methylphenyldiethoxysilane undergo hydrolysis and condensation reaction between 80~100°C, adjust the valve position on the discharge pipeline of the distillation head, and slowly receive the ethanol produced by the reaction- water mixture. After reacting ...

Embodiment 3 and Embodiment 4

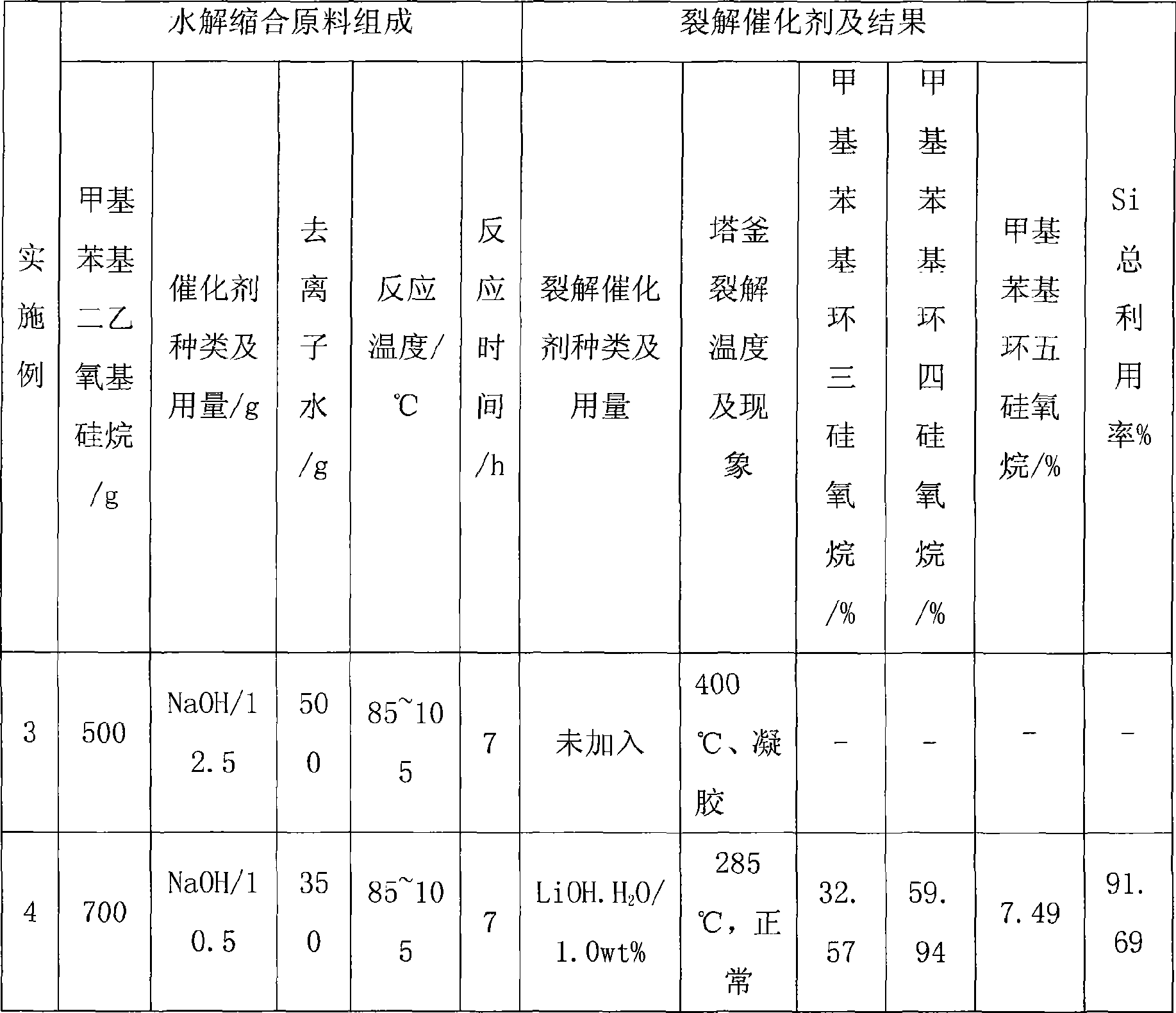

[0047] Except changing the kind and consumption of hydrolysis condensation catalyst, cracking catalyst, temperature of reaction and the reaction time, all the other conditions are with embodiment 1, carry out experiment according to the procedure identical with embodiment 1, gained result is shown in the table below.

[0048] The following table is embodiment 3 and 4 raw material proportioning, reaction conditions and reaction result

[0049]

[0050] By the same method as in Example 1, the methylphenyl mixed ring body prepared in Example 4 is used to replace the methylphenyl mixed ring body in Example 1 to prepare methylphenylethylene with a phenyl molar fraction of 20%. Base raw rubber, analyzed by GPC, relative to polystyrene, its molecular weight is 5.79×10 5 g / mol; Take 2g of methyl phenyl vinyl raw rubber sample, put it in 25mL of toluene solution, stir at room temperature, after 1h, the sample is completely dissolved in toluene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com