Corrosion resistant metal composite for electrochemical devices and methods of producing the same

A metal composite material, electrochemical technology, applied in the direction of metal material coating process, electrochemical generator, gaseous chemical plating, etc., can solve problems such as difficulty in obtaining consistency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Corrosion Resistance and Electrical Contact Resistance of Nitrided and Unnitrided Alloys

[0027] Ex-situ corrosion experiments were performed in relatively harsh environments typically encountered within PEM fuel cells under cyclic conditions of relative humidity, such as 40-100% RH. Thermally nitrided and unnitrided Hastelloy alloys G-30 and G-35 were tested in a degassed simulated fuel cell solution containing 10 ppm hydrogen fluoride (HF) at pH 3 at 80°C .

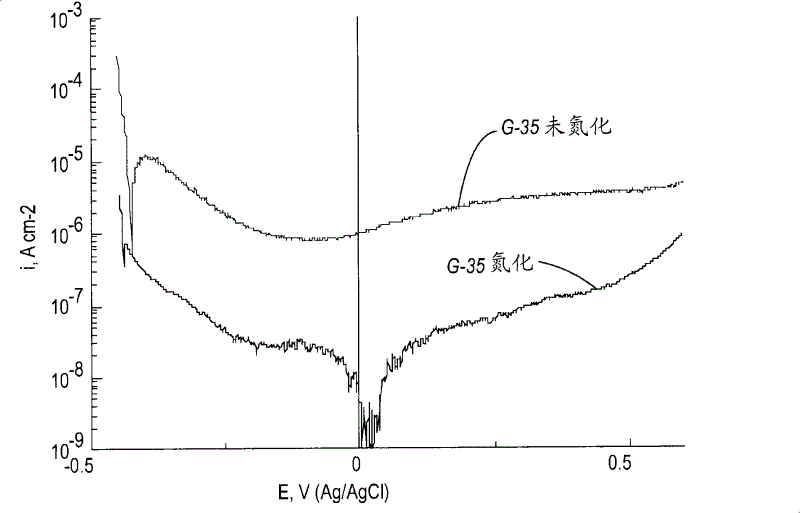

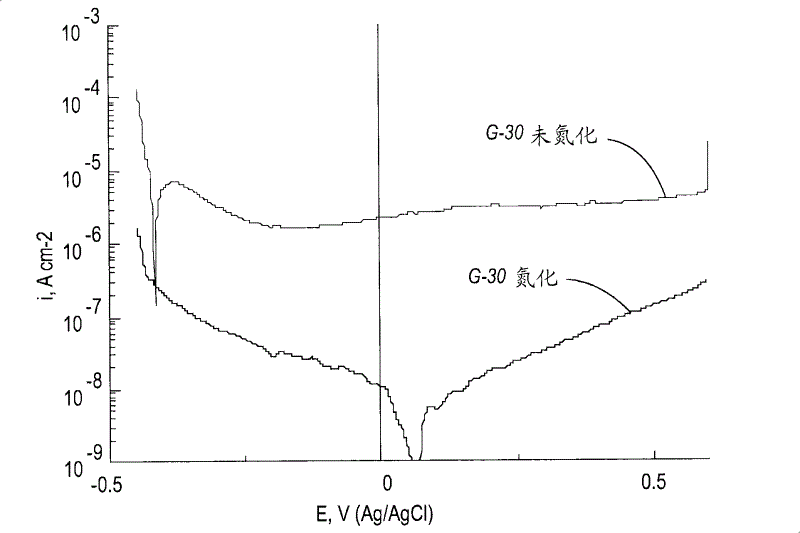

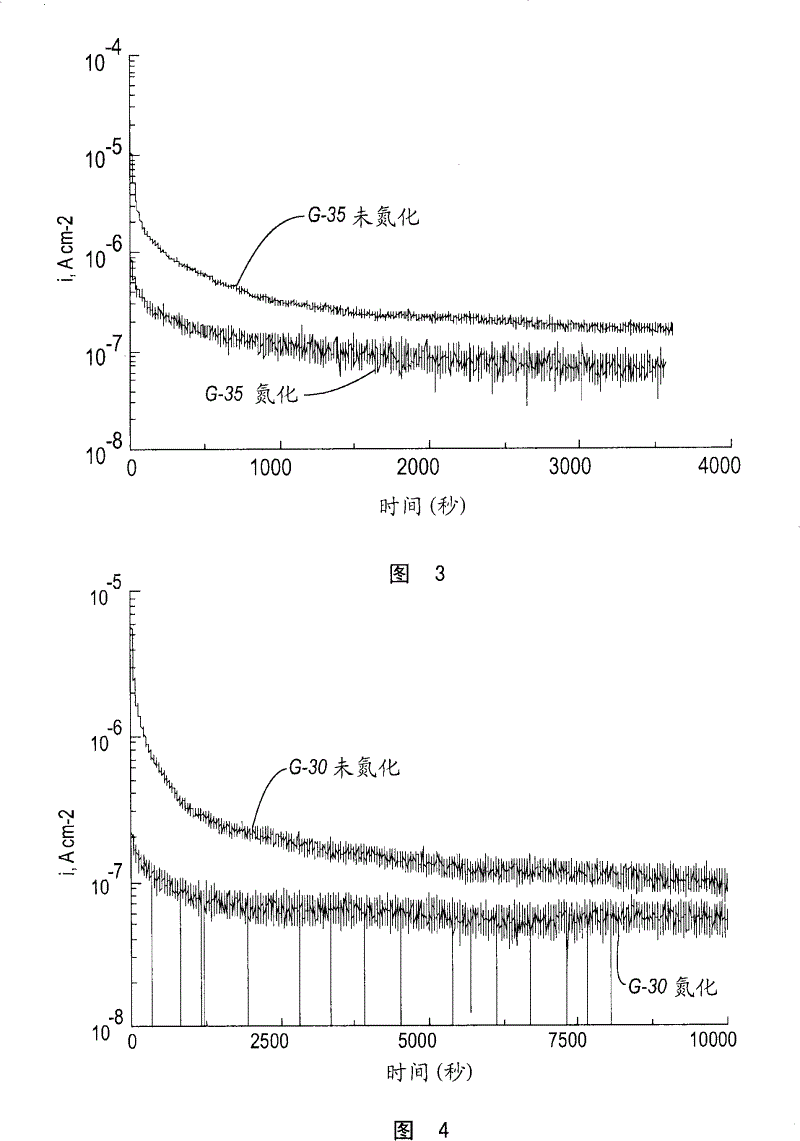

[0028] The potentiodynamic polarization curves of G-35 and G-30 alloys were obtained and shown in figure 1 and figure 2 middle. The current densities of the nitrided G-35 and G-30 alloys were an order of magnitude lower than their unnitrided counterparts over the range of electrode potentials tested. Lower current densities in potentiodynamic polarization tests indicate lower corrosion rates.

[0029] At 80 °C, at pH 3, in an argon-purged simulated fuel cell solution containing 10 ppm HF, at +0....

Embodiment 2

[0033] Example 2: Electrochemical Fuel Cell with Alloy Nitride Bipolar Plates

[0034] Single fuel cell tests were performed on metal plates of machined and thermally nitrided G-35 (anode and cathode). The fuel cell potential and / or current was controlled using a Global Tech test station controlled by Scribner software. used a 25μm thickness and loaded with 0.4mg cm -2 (Each side) Platinum Gore 5051 Membrane Electrode Assembly (MEA). The experiments were performed using hydrogen and air at a pressure of 25 psig, cyclic relative humidity, and a temperature of 80°C.

[0035] like Figure 5 As shown, a duration of almost 900 hours was collected on the nitrided G-35 alloy with little change in cell voltage or current density. It turns out that such a nitrided alloy as the outer layer of a bipolar plate would work very well in a fuel cell. Furthermore, ICP (Inductively Coupled Plasma) metal analysis of product water collected from the fuel cell showed below the detection limit...

Embodiment 3

[0036] Example 3: Metal composite bipolar plate

[0037] Straight gas flow channels were produced by stamping a stainless steel sheet of AISI 304 type with a thickness of 100 μm. Hastelloy G-35 plates are thermally nitrided at about 1000-1200° C. for about 2-8 hours in nitrogen or a nitrogen / hydrogen gas mixture. A stamped stainless steel substrate and a nitrided G-35 alloy foil as a target were placed in a sputtering chamber. Evacuate the chamber to about 10 -5 Pascals, and then backfilled with inert argon to a pressure of approximately 0.1 to 10 Pascals. A stable plasma is generated in the chamber. A negative bias voltage was then applied to the nitrided G-35 alloy target to start the sputtering process. A relatively uniform layer of nitrided G-35 alloy of about 1 nm-3 μm was deposited on the outer surface of the stainless steel, depending on the sputtering time. The result is a metal composite bipolar plate comprising low-cost stainless steel internal components and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com