Nanosized gold catalyst used for preparing propylene oxide by direct propylene oxidation and preparation method thereof

A propylene oxide and nano-gold technology, which is applied in catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of low catalyst activity and easy deactivation of catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

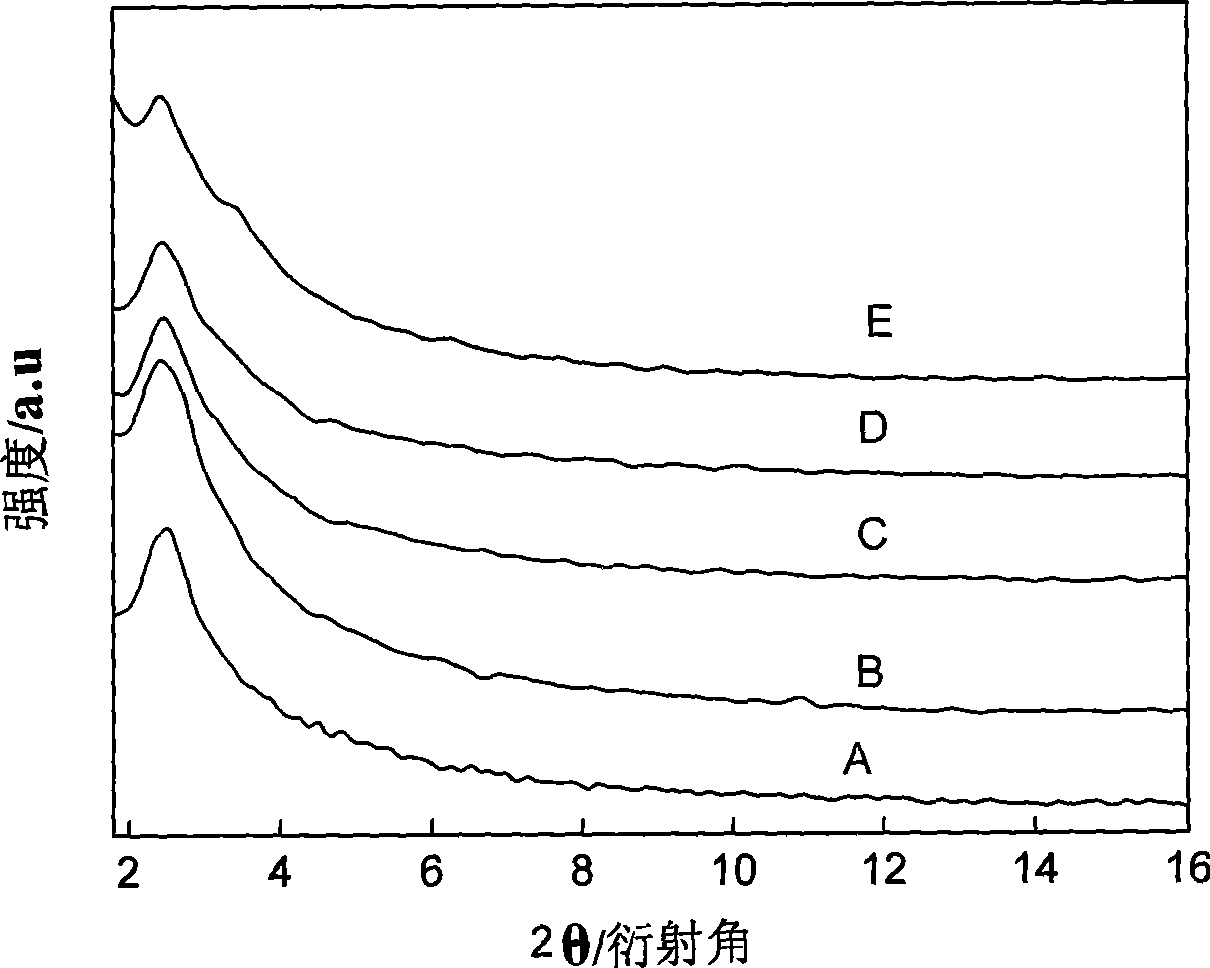

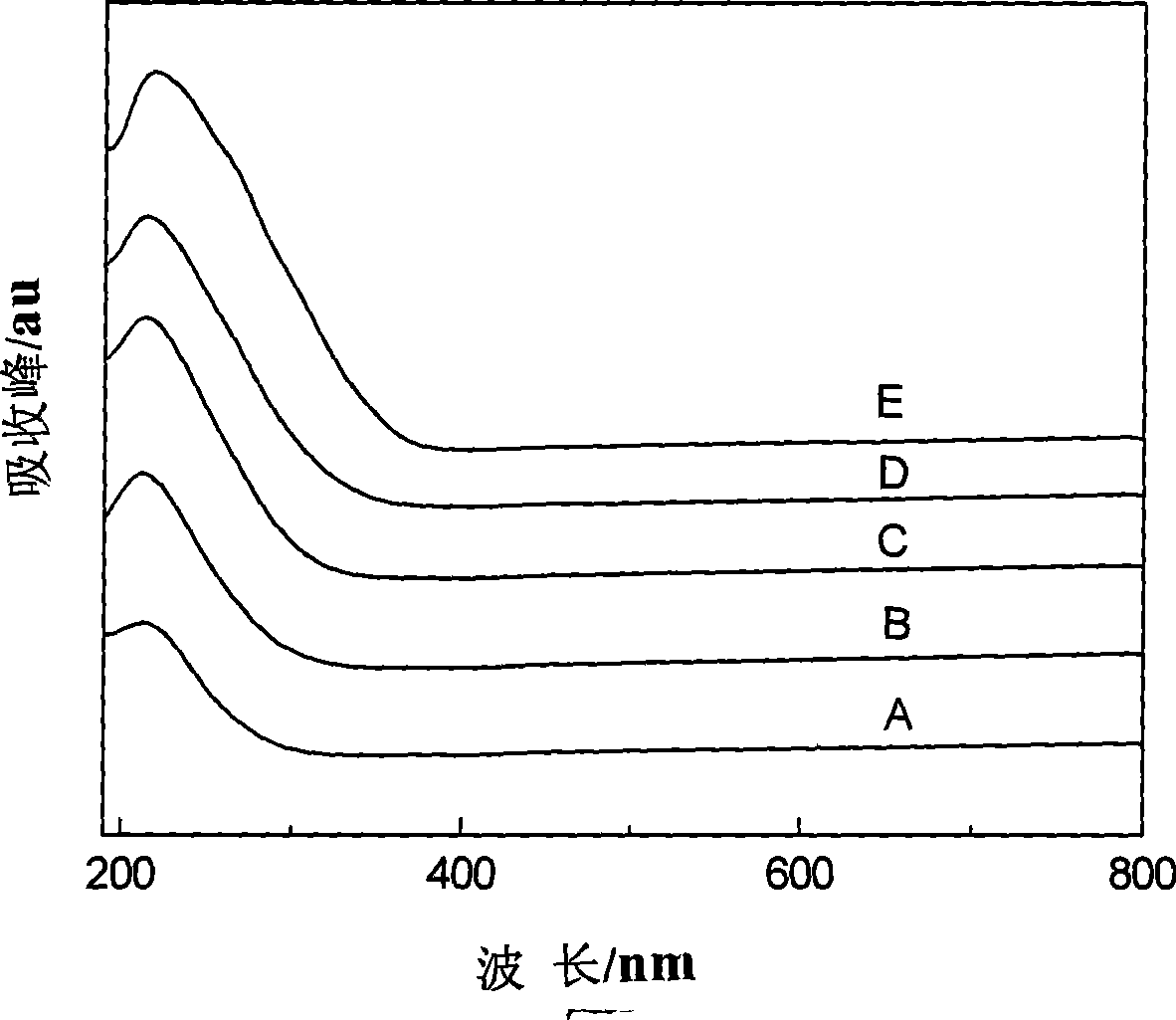

[0028] Example 1: Preparation of mesoporous-microporous composite titanium-silicon molecular sieve carrier

[0029] Dissolve 1.02 grams of tetrabutyl titanate in an appropriate amount of isopropanol and add it to 62.4 grams of tetraethyl orthosilicate, stir and mix evenly, place in an ice-water bath, slowly add 60 grams of tetrapropyl titanate dropwise under vigorous stirring Ammonium hydroxide solution (20 wt%) was added thereto. Continue to stir the reaction for 1-2 hours after the dropwise addition, and then slowly raise the temperature to about 70 degrees, evaporate and remove the isopropanol and the ethanol solvent produced by the hydrolysis of ethyl orthosilicate therein. Finally, add 60 grams of water, continue stirring and reacting for 1-2 hours, then transfer to a PTFE-lined autoclave, react statically in a drying oven at 100°C for 3 hours, then cool to room temperature to obtain a microporous molecular sieve precursor sol. 33 g of cetyltrimethylammonium bromide were...

Embodiment 2

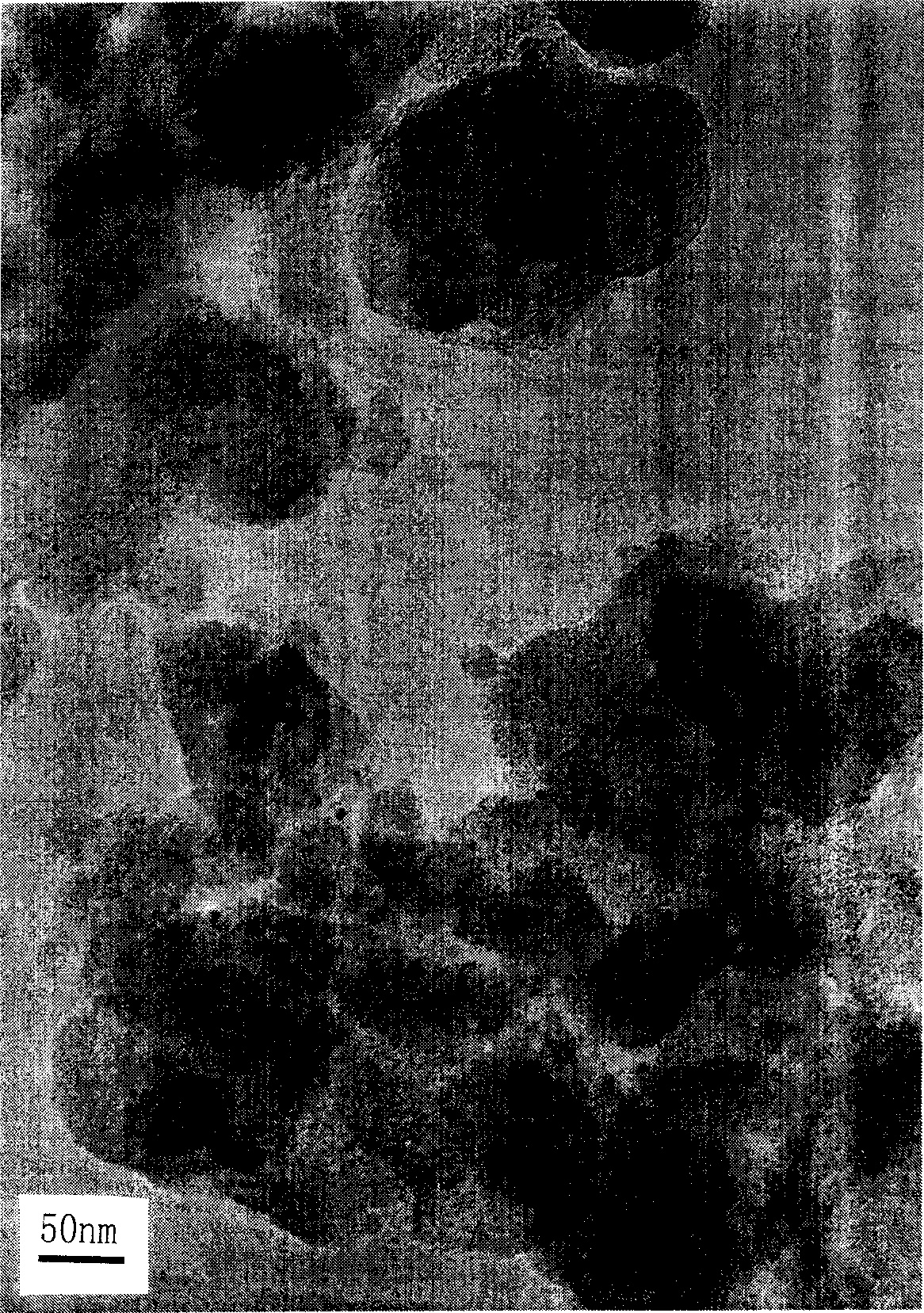

[0030] Embodiment 2: the preparation of nano gold catalyst

[0031] Heat 100ml of chloroauric acid solution (2.4mM) to 70°C with 1M N 2 CO 3 The pH of the solution was adjusted to 8.9. Add 1 gram of the titanium-silicon molecular sieve carrier prepared in Example 1 under vigorous stirring, and after stirring and reacting for 15 minutes, add 5ml of 0.04mol / L Ba(NO 3 ) 2 The solution was stirred at the same temperature for 45 minutes. After being cooled to room temperature, the obtained sample was separated by suction filtration, washed with 50 milliliters of distilled water, dried overnight in a vacuum oven at room temperature, and finally calcined at 300 ° C for 4 hours to obtain a nano-gold catalyst. The TEM photo of the catalyst is attached image 3 As shown, the average particle size of the gold nanoparticles is 2-3nm.

Embodiment 3

[0032] Example 3: Preparation of Propylene Oxide by Direct Oxidation of Propylene under Hydrogen / Oxygen Coexistence Conditions

[0033]The catalytic performance of nano-gold catalysts was evaluated on a quartz tube microreactor with an inner diameter of 8 mm. The catalyst consumption is 0.3g, the flow rates of hydrogen, oxygen, propylene and nitrogen are 3.5, 3.5, 3.5 and 24.5ml / min respectively, the space velocity is 7000, and the reaction pressure is 0.1MPa. Before starting the reaction, the catalysts were separately treated with 12.5 Vol% H at 250 °C 2 and O 2 Pretreatment for 30min, then lower the temperature to 150°C in N2 atmosphere, and pass H 2 、C 3 h 6 and O 2 start reacting. The reaction products were analyzed online by gas chromatography equipped with FID and TCD. Catalyst performance was measured and compared in terms of propylene conversion, propylene oxide selectivity, and propylene oxide formation rate. The catalytic reaction results are listed in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com