Method for preparing gamma-AlON ceramic powder based on carbon thermal reduction nitridation

A ceramic powder and nitriding technology, which is applied in the field of rapid preparation of γ-AlON transparent ceramic powder, can solve the problems of slow synthesis process, expensive raw materials, and incomplete reaction, and achieve uniform and fine particle size, complete reaction transformation, and inhibition The effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The selected mass ratio is γ-Al 2 o 3 :starch=4:1. First weigh γ-Al in proportion 2 o 3 Add 8g of powder and 2g of starch, add 100ml of distilled water, and use alumina balls as the medium to ball mill and mix for 24 hours to obtain a slurry; take out the slurry and dry it under vacuum at 100°C to evaporate the water; put the dried powder in Under argon atmosphere, heat treatment in a tube furnace at 400°C for 12 hours to dehydrate to form γ-Al 2 o 3 and carbon precursor powder; the precursor powder is placed in a crucible, the crucible is placed in a graphite reactor, and the graphite reactor is placed in a high-current reaction synthesis device, nitrogen gas is introduced and the flow of the atmosphere is maintained throughout the heating process The synthesis temperature is 1500°C, the heating rate is 50°C / min, and the heat preservation is 50min to obtain the carbon-containing mixed powder; after cooling down, the carbon-containing mixed powder is taken out and ...

Embodiment 2

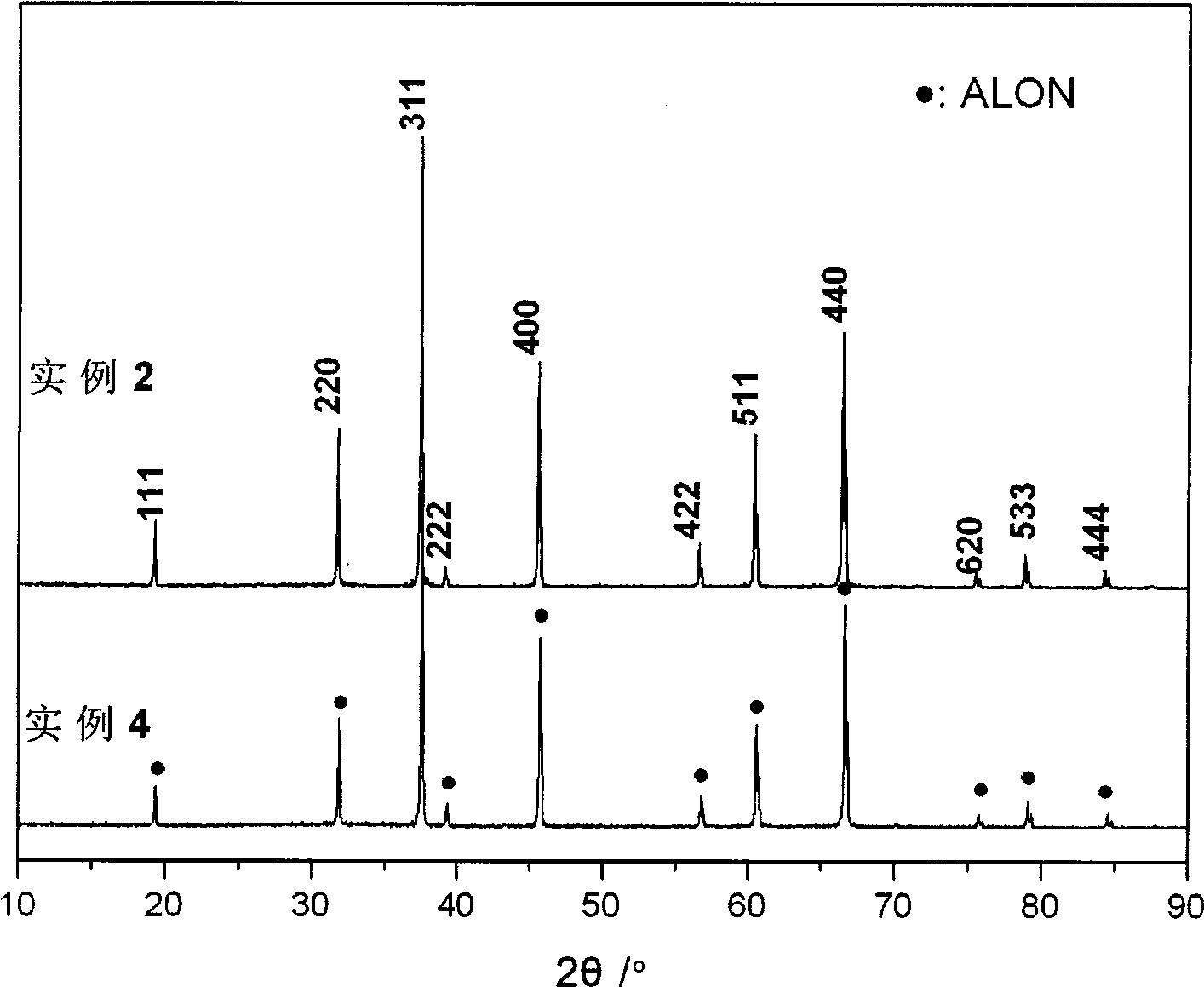

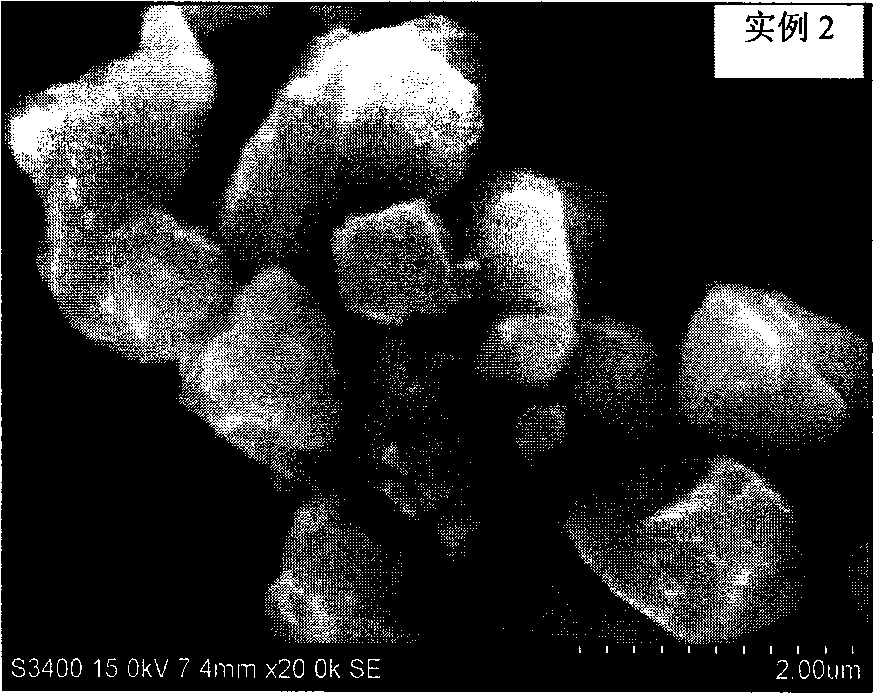

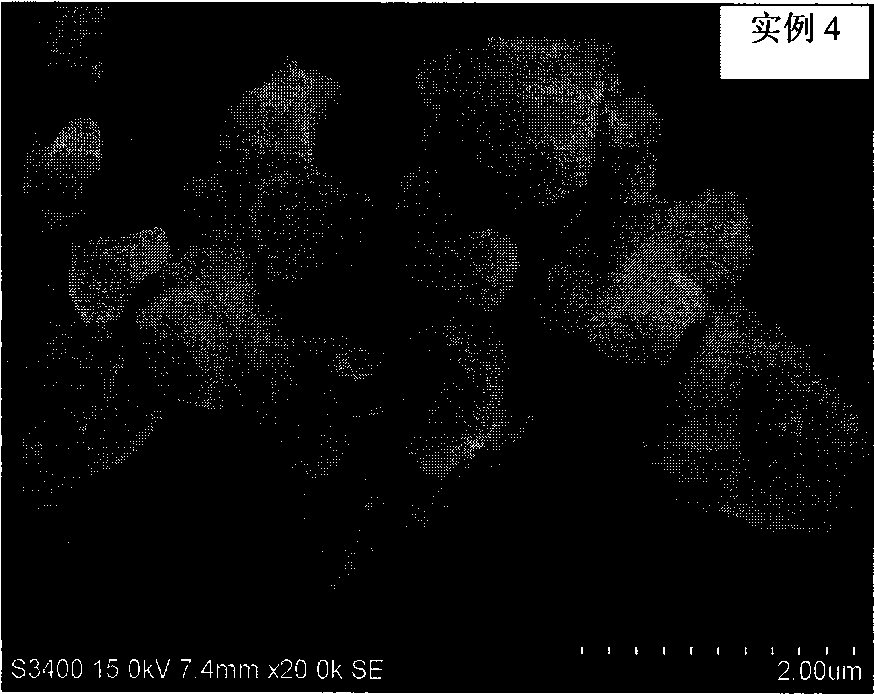

[0027] The selected mass ratio is γ-Al 2 o 3 :starch=10:2.6. First weigh γ-Al in proportion 2 o 3 Add 10g of powder and 2.6g of starch, add 100ml of absolute ethanol, and use alumina balls as the medium to ball mill and mix for 48 hours to obtain a slurry; take out the slurry and dry it under vacuum at 70°C to volatilize the ethanol; the dried powder Under argon atmosphere, heat treatment in a tube furnace at 450°C for 10h to dehydrate to form γ-Al 2 o 3 and carbon precursor powder; the former precursor powder is placed in a crucible, the crucible is placed in a graphite reactor, and the graphite reactor is placed in a high-current reaction synthesis device, nitrogen gas is introduced and the flow of the atmosphere is maintained throughout the heating process The synthesis temperature is 1550°C, the heating rate is 100°C / min, and the heat preservation is 35 minutes to obtain the carbon-containing mixed powder; after cooling down, the carbon-containing mixed powder is take...

Embodiment 3

[0029] The selected mass ratio is γ-Al 2 o 3 :starch=4:1. First weigh γ-Al in proportion 2 o 3 Add 8g of powder and 2g of starch, add 100ml of distilled water and mix evenly (using alumina balls as the medium for ball milling and mixing for 36h) to obtain a slurry; take out the slurry and dry it under vacuum at 100°C to volatilize the water; the dried powder The body was heat-treated in a tube furnace at 500 °C for 6 h in an argon atmosphere to form γ-Al 2 o 3 and carbon precursor powder; the former precursor powder is placed in a crucible, the crucible is placed in a graphite reactor, and the graphite reactor is placed in a high-current reaction synthesis device, nitrogen gas is introduced and the flow of the atmosphere is maintained throughout the heating process The synthesis temperature is 1600°C, the heating rate is 200°C / min, and the heat preservation is 30 minutes to obtain the carbon-containing mixed powder; after cooling down, the carbon-containing mixed powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com