Method for preparing water soluble polyethylene glycol/polylactic segmented polycarbonate resin

A technology of polyethylene glycol and polycarbonate, which is applied in the field of preparation of water-soluble polyethylene glycol/polylactic acid multi-block polycarbonate, can solve the problems of inconvenient transportation and storage, and achieve low toxicity and wide application Prospect, effect of reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

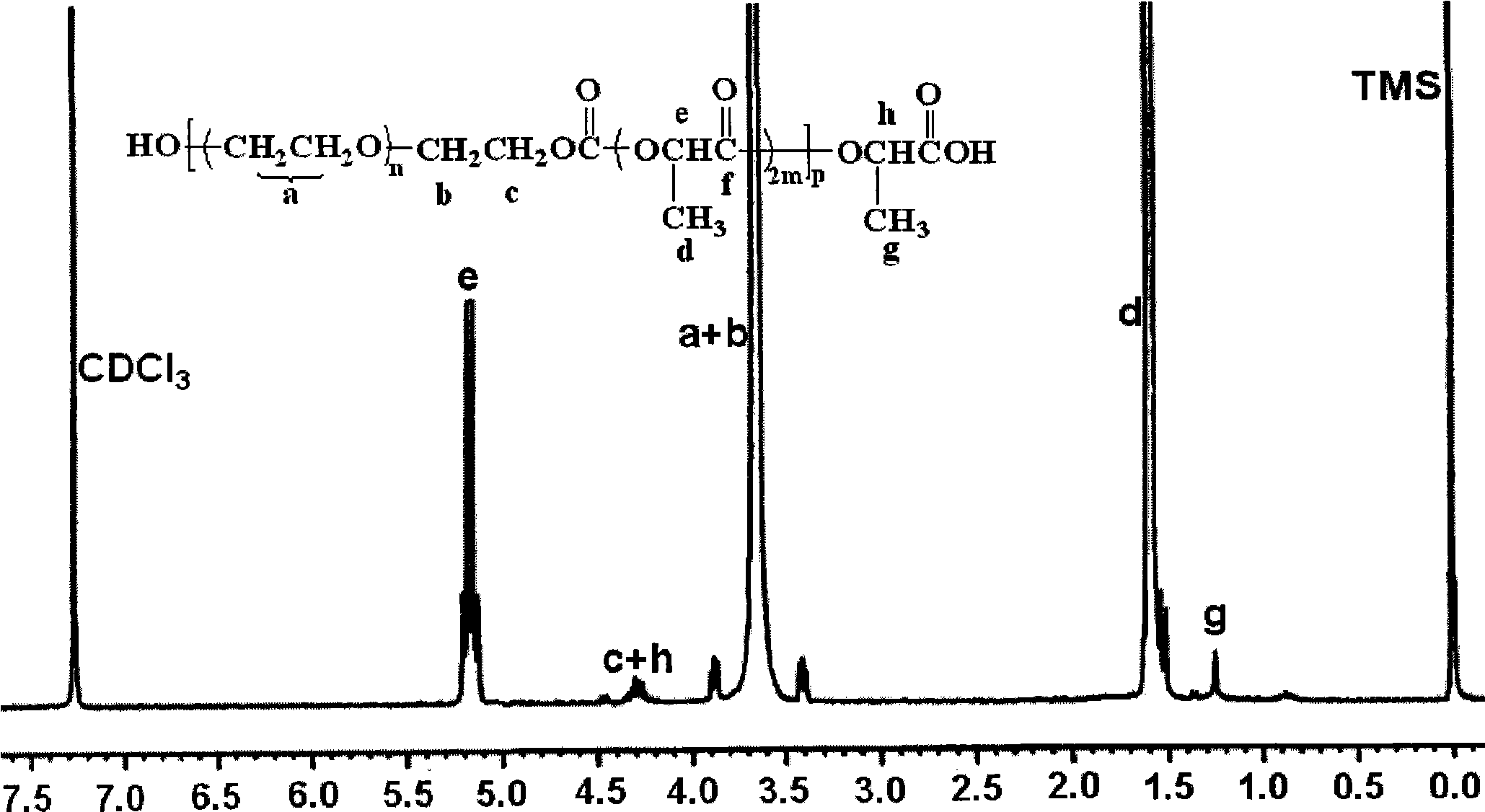

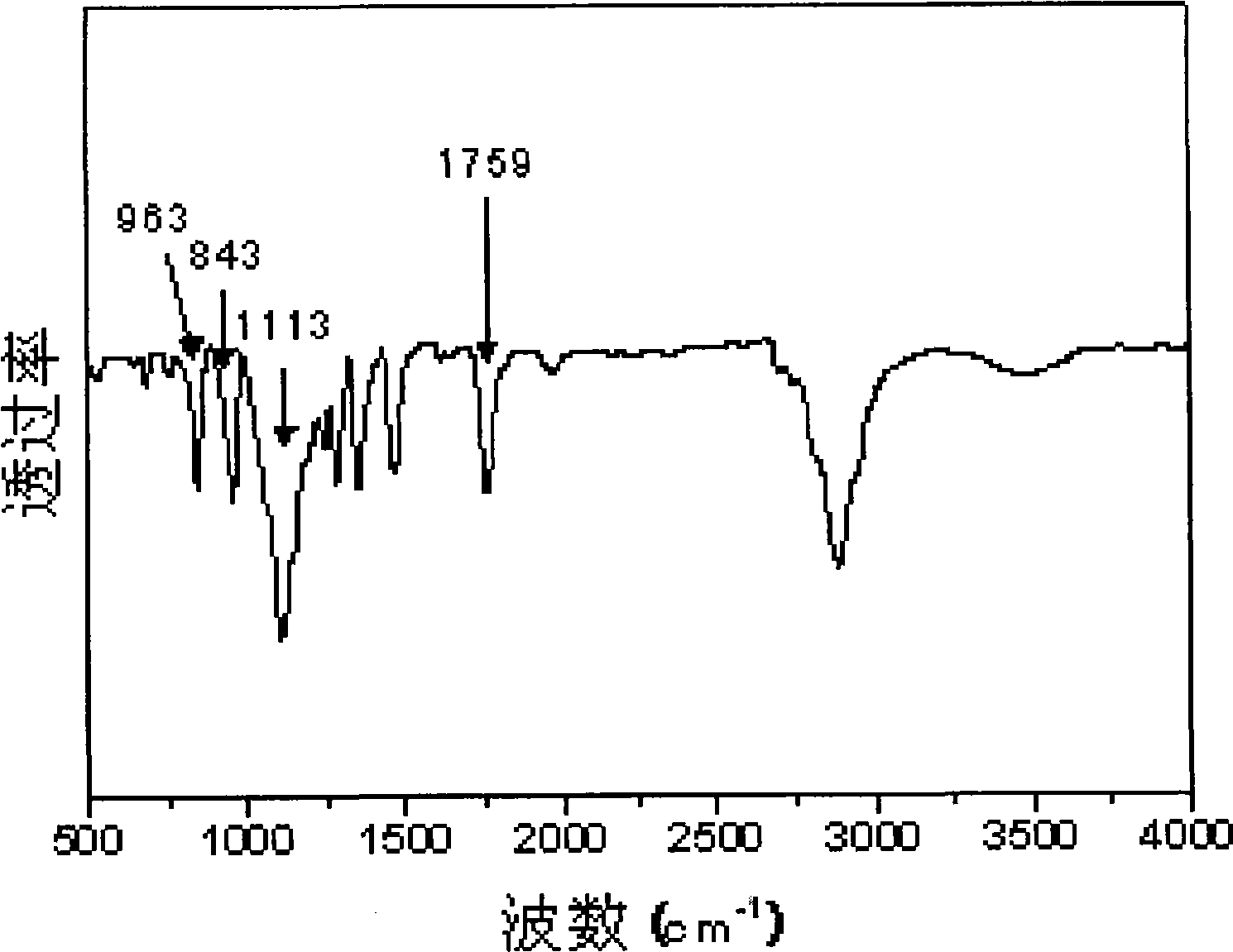

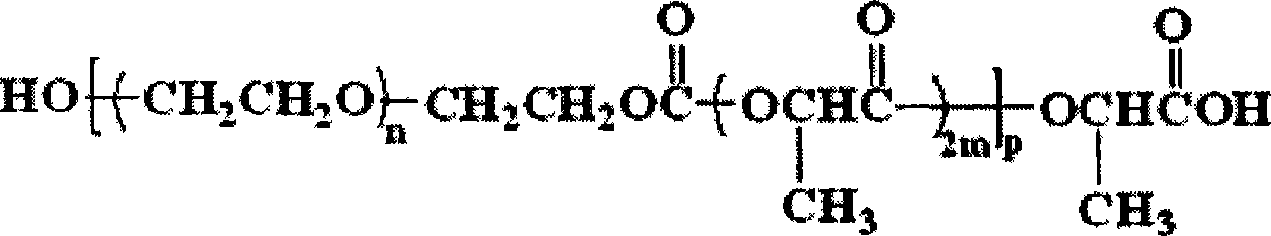

[0042] A preparation method of water-soluble polyethylene glycol / polylactic acid multi-block polycarbonate, the steps are as follows:

[0043] (1) Weigh 12.00g PEG6000 and 5.76g L-LA, and place them in a fully washed and dried three-necked flask. After 30 minutes of flowing nitrogen, start heating, and after melting into a homogeneous phase, add 0.88 g of stannous octoate, and react at 150°C for 24 hours under the protection of nitrogen. The product was dissolved in 10 mL of dichloromethane, and then 100 mL of methanol was added to obtain a white precipitate to obtain a PLA-PEG-PLA triblock copolymer.

[0044] (2) Take by weighing 4.44g PLA-PEG-PLA triblock copolymer and join in the round-bottomed flask that condenser tube, thermometer, constant pressure dropping funnel and magnetic force stirring are housed, and measure 15mL dichloromethane and pour into, Airtight, magnetic stirring to completely dissolve the solid, and an anhydrous calcium chloride drying tube on the conden...

Embodiment 2

[0051] As described in Example 1, the difference is that the amount of L-LA is changed, and 4.32g is dropped into to obtain 2.23g of a viscous solid product of water-soluble polycarbonate with a thermally reversible gel effect, the yield is 65.40%, and the weight average molecular weight for 51900.

Embodiment 3

[0053] As described in Example 1, the difference is that the amount of L-LA is changed, and 7.20 g is added to obtain 3.12 g of a viscous solid product of water-soluble polycarbonate with a thermally reversible gel effect, with a yield of 57.09%, and a weight-average molecular weight for 68500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com