Preparation of CaTiO3-coated calcium oxide-based CO2 absorbent

A technology of surface coating and calcium oxide, applied in the direction of inorganic chemistry, carbon compounds, other chemical processes, etc., can solve problems such as difficult industrial application, micropore blockage, industrial application restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

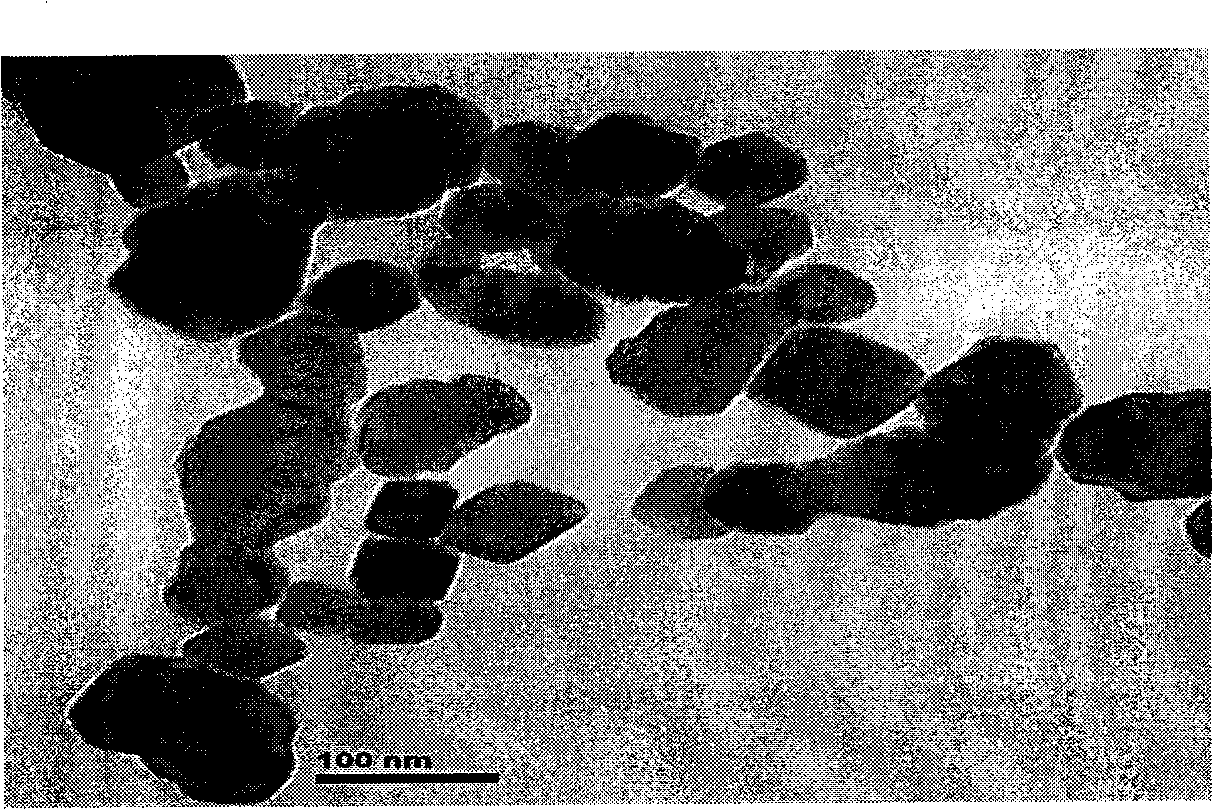

[0052] (1) Dissolve 2.85 g of ethyl titanate in 100 ml of absolute ethanol to form a uniform transparent solution.

[0053] (2) Disperse 9 g of nano calcium carbonate with a particle size of 50 nm in the above solution using an ultrasonic disperser.

[0054] (3) Stir and drop 3ml of distilled water, and continue to stir for 3 hours.

[0055] (4) Filter with suction and dry until the ethanol and excess water have evaporated, then grind the solid sample to obtain Ti(OH) 4 Coated nano calcium carbonate.

[0056] (5) The obtained Ti(OH) 4 The coated nano-calcium carbonate is heat-treated at 400℃ for 5 hours, and the heating rate is: 20℃ / min to obtain TiO 2 Coated nano calcium carbonate.

[0057] (6) The obtained TiO 2 The coated nano-calcium carbonate is calcined under 750℃ air atmosphere for 3 hours, the heating rate is: 20℃ / min, and the surface is coated with CaTiO 3 Nano calcium oxide adsorbent.

[0058] Performance test: The prepared adsorbent is subjected to 10 decarburization-ca...

Embodiment 2

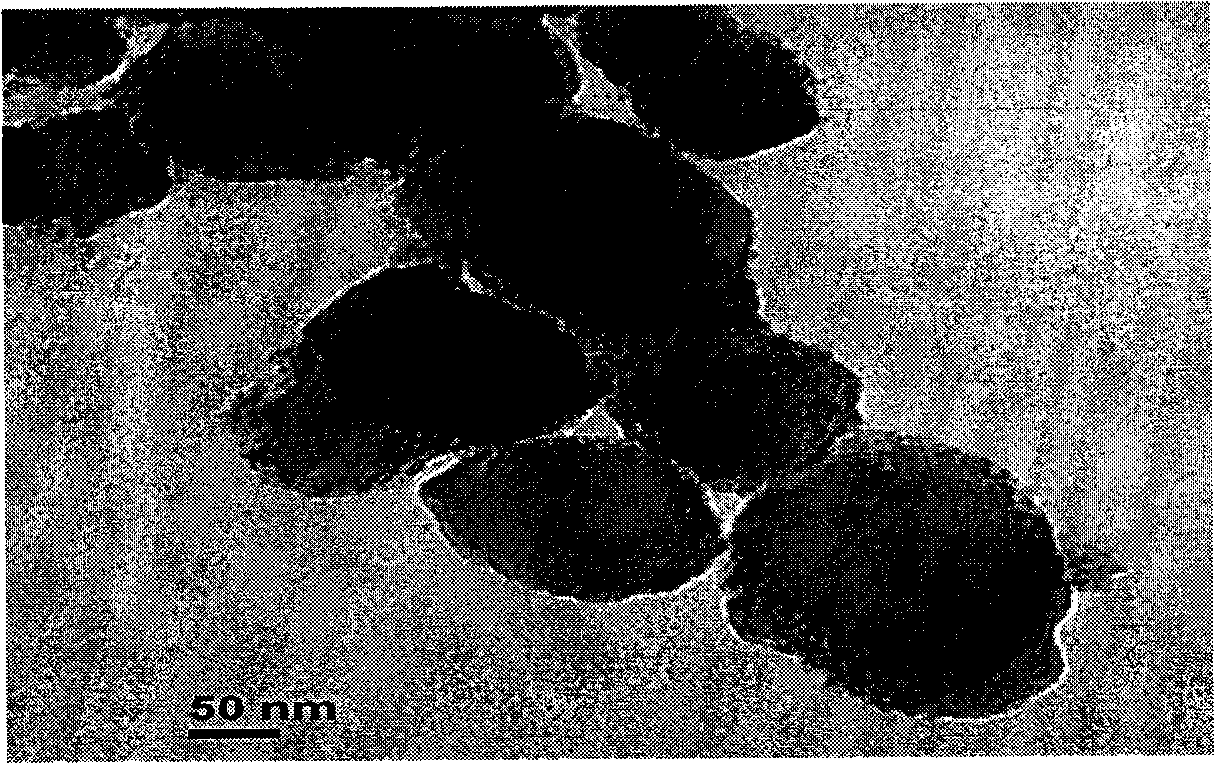

[0063] (1) Dissolve 3.55 g of isopropyl titanate in 100 ml of absolute ethanol to form a uniform transparent solution.

[0064] (2) Disperse 9 g of nanometer calcium carbonate with a particle size of 70 nm in the above solution using an ultrasonic disperser.

[0065] (3) Stir and drop 4 ml of distilled water, and continue to stir for 2 hours.

[0066] (4) Filter with suction and dry until the ethanol and excess water have evaporated, then grind the solid sample to obtain Ti(OH) 4 Coated nano calcium carbonate.

[0067] (5) The obtained Ti(OH) 4 The coated nano-calcium carbonate is heat-treated at 500℃ for 4 hours, and the heating rate is: 20℃ / min to prepare TiO 2 Coated nano calcium carbonate.

[0068] (6) The obtained TiO 2 The coated nano-calcium carbonate is calcined under 800℃ air atmosphere for 3 hours, the heating rate is 30℃ / min, and the surface is coated with CaTiO 3 Nano calcium oxide adsorbent.

[0069] Performance test: The prepared adsorbent is subjected to 10 decarbur...

Embodiment 3

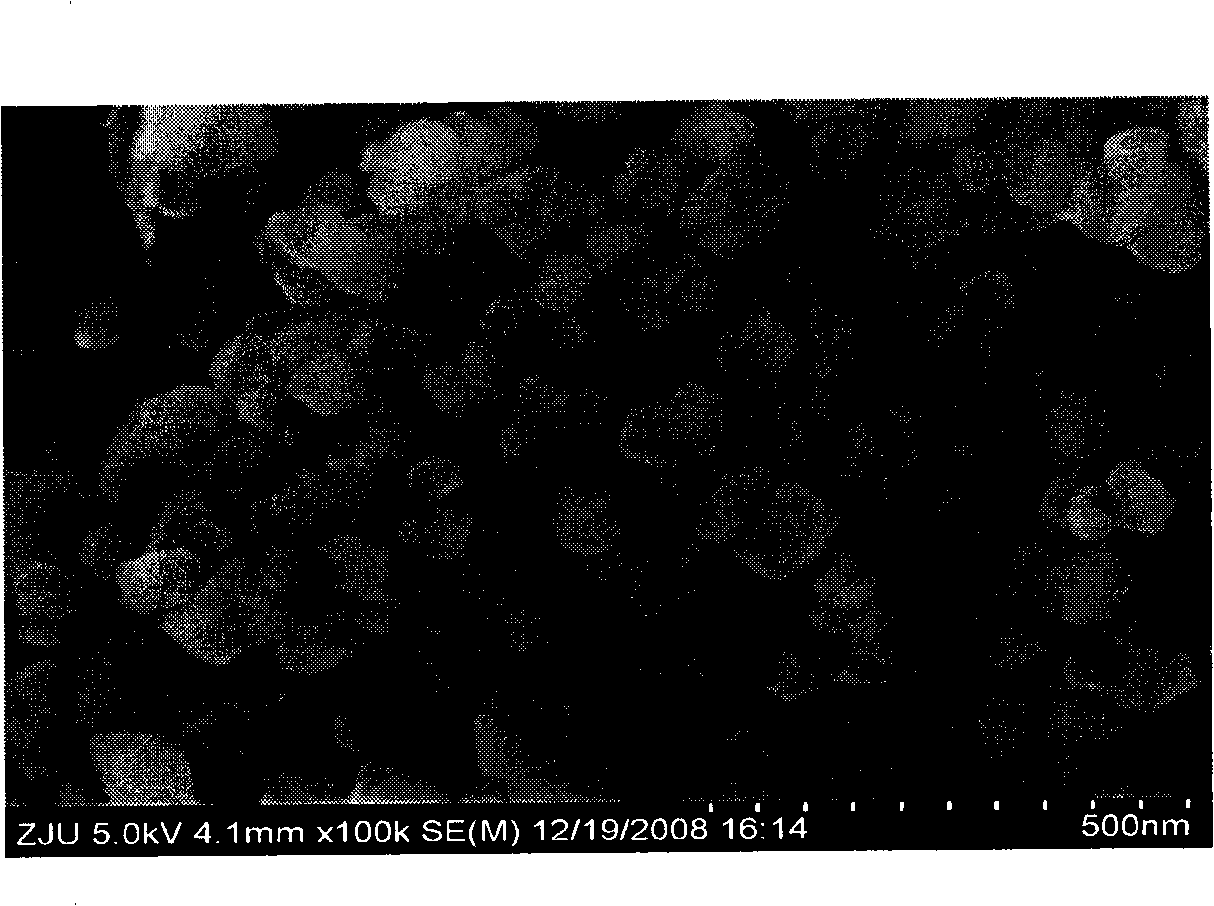

[0071] (1) Dissolve 4.26 g of butyl titanate in 200 ml of water ethanol to form a uniform transparent solution.

[0072] (2) Disperse 9 g of nano calcium carbonate with a particle size of 50 nm in the above solution using an ultrasonic disperser.

[0073] (3) Stir and drop 3ml of distilled water, and continue to stir for 5 hours.

[0074] (4) Filter with suction and dry until the ethanol and excess water have evaporated, then grind the solid sample to obtain Ti(OH) 4 Coated nano calcium carbonate.

[0075] (5) The obtained Ti(OH) 4 The coated nano-calcium carbonate is heat-treated at 600℃ for 3 hours, and the heating rate is 30℃ / min to obtain TiO 2 Coated nano calcium carbonate.

[0076] (6) The obtained TiO 2 The coated nano-calcium carbonate is calcined under 900℃ air atmosphere for 2 hours, the heating rate is 30℃ / min, and the surface is coated with CaTiO 3 Nano calcium oxide adsorbent.

[0077] Performance test: The prepared adsorbent is subjected to 10 decarburization-carboni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com