Composite building insulation slurry

A kind of building insulation and composite technology, applied in the field of building slurry, can solve the problems of thermal conductivity, bonding strength, fire resistance level difficult to meet national standards, deformation, shedding and other problems, achieve low cost, reasonable composition of ingredients, prevent shrinkage turtles cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] 1. Preparation

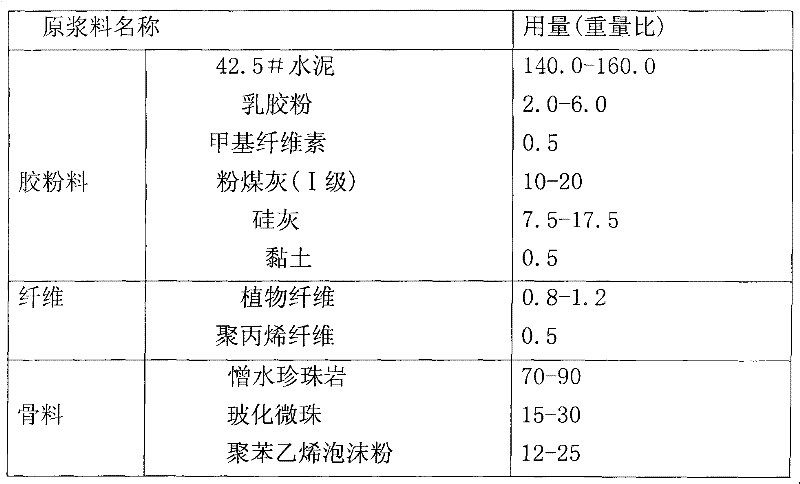

[0010] The composite building thermal insulation slurry of the present invention is composed of the following materials in parts by weight: the cementing material is composed of 140.0-160.0 parts of 42.5# ordinary cement, 2.0-6.0 parts of latex powder, and 0.5 parts of methyl cellulose; The aggregate is composed of 70-90 parts of hydrophobic perlite, 15-30 parts of vitrified microbeads, and 12-25 parts of polystyrene foam powder; the fiber is composed of 0.8-1.2 parts of plant fiber and 0.5 part of polypropylene fiber The additives are composed of 10-20 parts of fly ash, 7.5-17.5 parts of silica fume, and 0.5 parts of clay. Weigh and mix the above materials evenly, and add an appropriate amount of water to stir them into a slurry.

[0011] The mix ratio of composite building thermal insulation slurry is as follows:

[0012]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com