Method for directly producing sodium stannate from flue dust and tin containing chemical engineering sludge

A technology for the production of sodium stannate and chemical sludge, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problems of wasting precious resources, environment, pollution, etc., and achieve the reduction of production process, simple process, and reduction of production The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

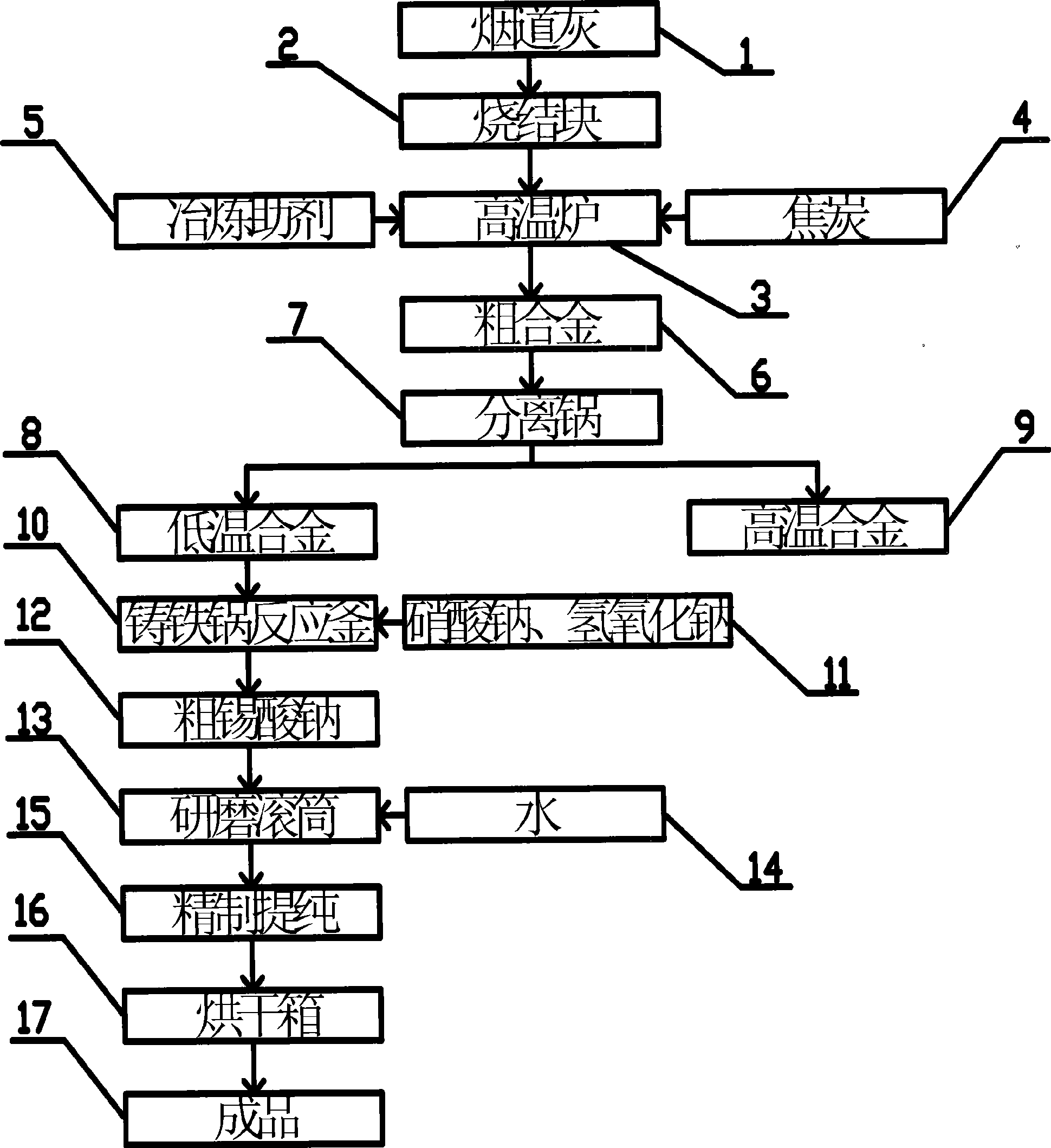

[0016] refer to figure 1 , figure 1 It is a process flow diagram of an embodiment of a method for directly producing sodium stannate by using flue ash and tin-containing chemical sludge provided by the present invention: the chemical composition from a waste copper recovery plant is: Pb30%, Sb20% , Sn10%, Si15%, Ag2500g / t, Au20g / t, Zn16%, Cu9% flue ash 1 is made into agglomerated block with a press or artificially, and then fired to make agglomerate 2; The agglomerate 2, coke 4 and smelting auxiliary agent 5 are put into the high temperature furnace 3 for smelting, the smelting auxiliary agent 5 described here is limestone and fluorite, and the consumption of the smelting auxiliary agent 5 is 6% of the sintering agglomerate 2; After the liquid metal is produced in the high temperature furnace 3, the crude alloy 6 is released from the high temperature furnace 3. The obtained crude alloy 6 is placed in the separation pot 7, and the low-temperature alloy 8 in it flows out from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com