Process for treating mine water in high efficiency

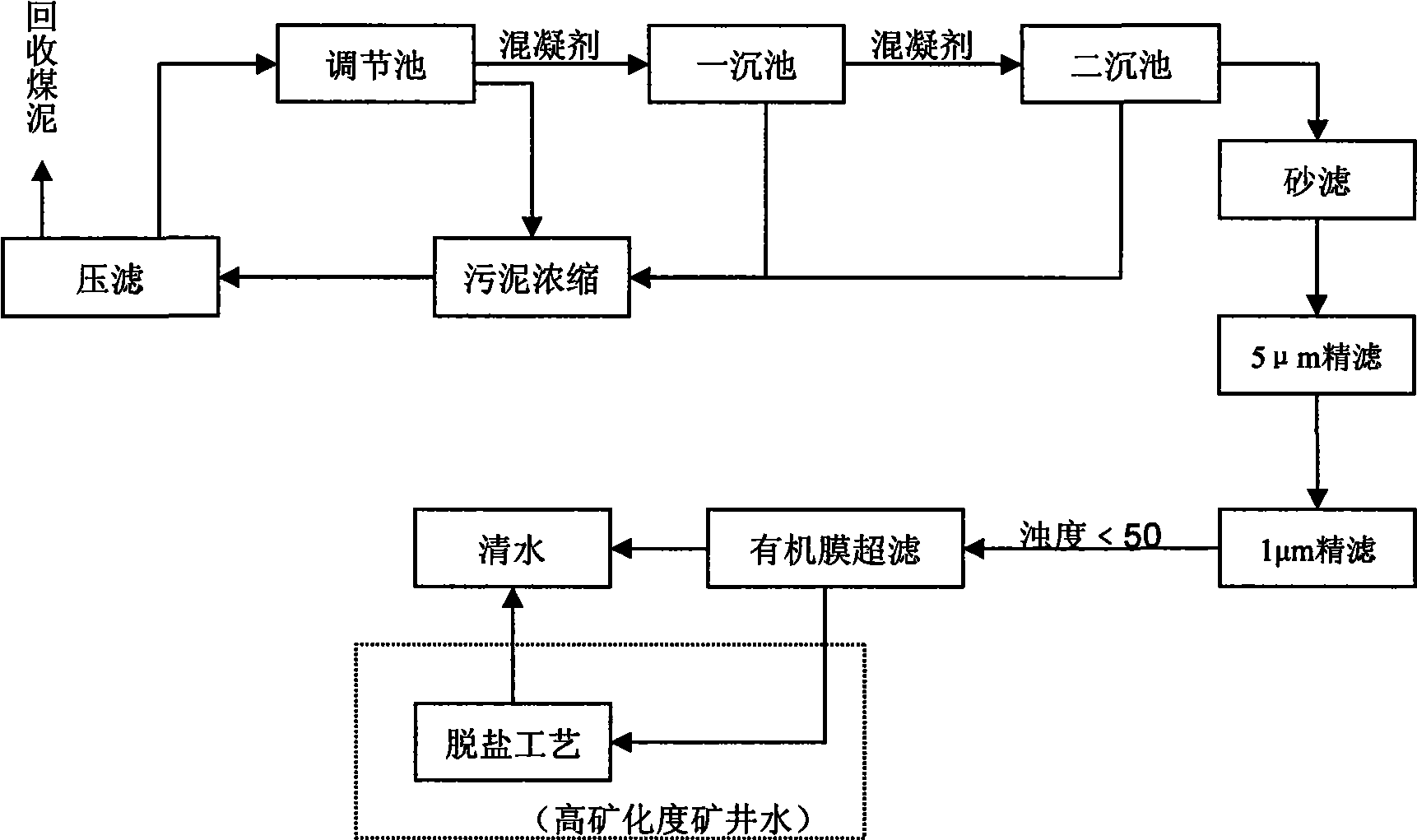

A treatment process, mine water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problem of short service life of organic membrane equipment and low temperature of flocculants Problems such as failure, easy pollution of organic filter membrane, etc., achieve the effects of small footprint, easy pollution, and short process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

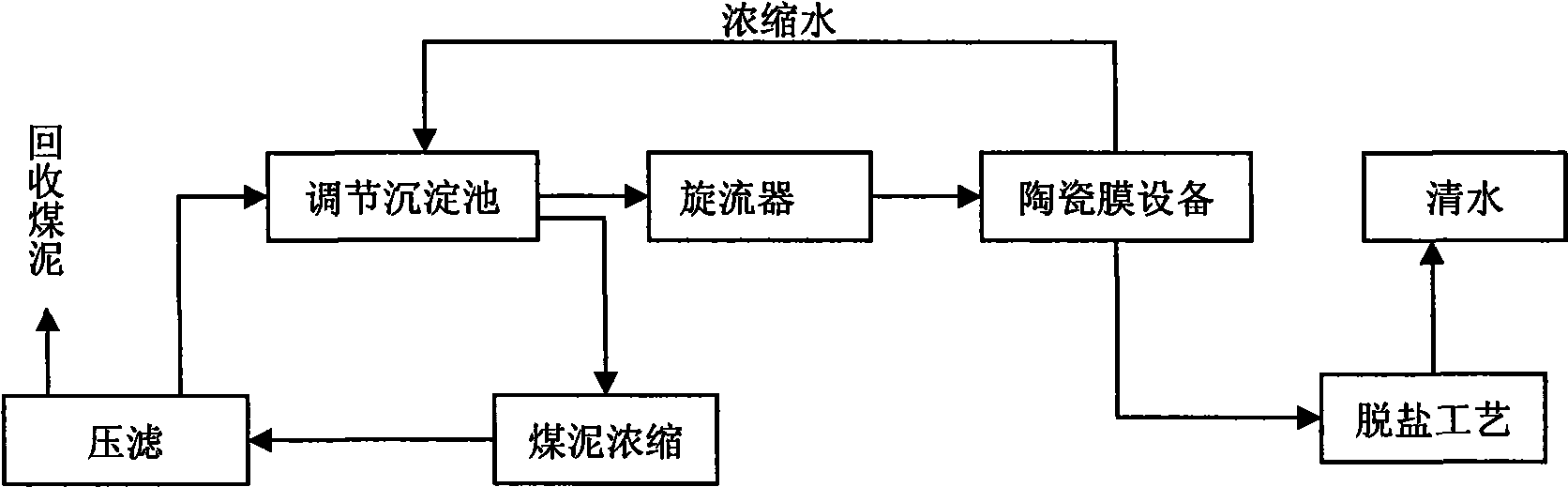

[0027] Example 1: Mine water with high suspended solids and high salinity

[0028] High-efficiency mine water treatment process, see the process flow figure 2 First, the mine water is introduced into the adjustment sedimentation tank for pre-sedimentation and homogenization, then an appropriate amount of CaO water, sodium hydroxide, sodium carbonate and gypsum are added to adjust the pH value to 8, and then it enters the cyclone for cyclone separation and filtration. Large solid particles larger than 2 mm are removed, and then enter ceramic membrane equipment for ceramic membrane cross-flow ultrafiltration, and the filtration precision of the ceramic membrane is 0.05-0.1 μm. The water after ceramic membrane ultrafiltration is desalinated to obtain treated mine water that meets drinking water standards; the concentrated water is poured into the regulating sedimentation tank for recycling treatment. The sludge settled in the sedimentation tank can be concentrated and filtered ...

Embodiment 2

[0029] Example 2: Mine water with high suspended solids and low salinity

[0030] High-efficiency mine water treatment process, the mine water is first introduced into the adjustment sedimentation tank for pre-sedimentation and homogenization, and then it is subjected to cyclone separation and filtration to remove large solid particles larger than 2mm in the mine water, followed by ceramic membrane cross-flow ultrafiltration. The filtering precision of the ceramic membrane is 0.05-0.1 μm, and the treated mine water meeting the domestic water standard can be obtained. The sludge settled in the sedimentation tank can be concentrated and filtered to recover the slime; the filtrate from the filter is circulated into the sedimentation tank for treatment. Before treatment, the bacteria content in the mine water was 15, and after treatment it was zero; the raw water turbidity was 680, and after treatment it was 0.4.

Embodiment 3

[0031] Embodiment 3: Mine water containing harmful ions such as fluorine, copper, lead, arsenic, chromium heavy metals

[0032]High-efficiency mine water treatment process, first introduce mine water into the adjustment sedimentation tank for pre-sedimentation and homogenization, then add appropriate amount of CaO water agent and sodium hydroxide to adjust the pH value to 8.5, so that harmful heavy metal substances form insoluble substances, and then carry out cyclone separation Filtration, the large solid matter larger than 2mm in the mine water is removed, and then the cross-flow ultrafiltration of the ceramic membrane is performed. The filtration accuracy of the ceramic membrane is 0.05-0.1 μm, and the treated mine water meeting the domestic water standard is obtained. The sludge settled in the sedimentation tank can be concentrated and filtered to recover the slime; the filtrate from the filter is circulated into the sedimentation tank for treatment. Before treatment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com