Manganese-based fluxing agent for converter steelmaking and preparation method thereof

A converter steelmaking and fluxing technology, which is applied in the direction of manufacturing converters, etc., can solve the problems of short fluxing action time and inability to continuously slag, fluorite erodes the converter lining, and the slag effect is not significant, so as to improve the slag. The effect of fluidity, sub-melting weakening, and reduction of sticking gun phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below by way of examples.

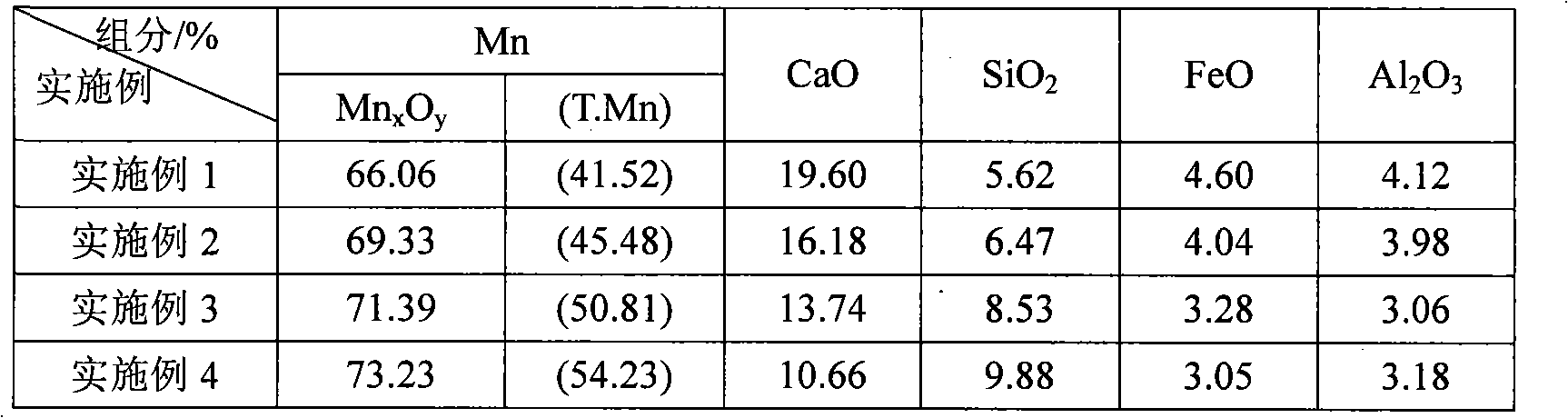

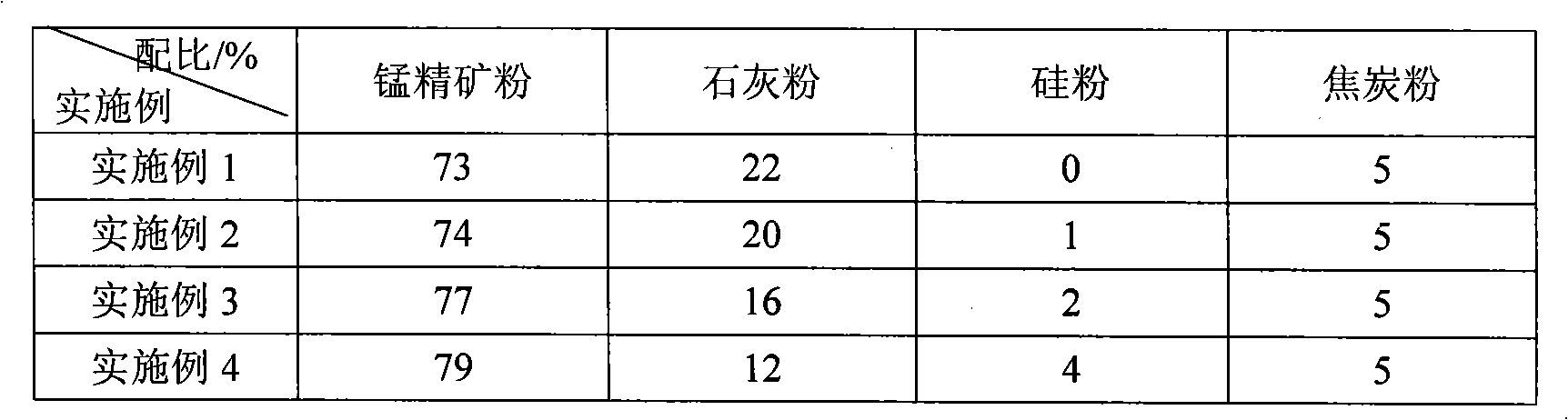

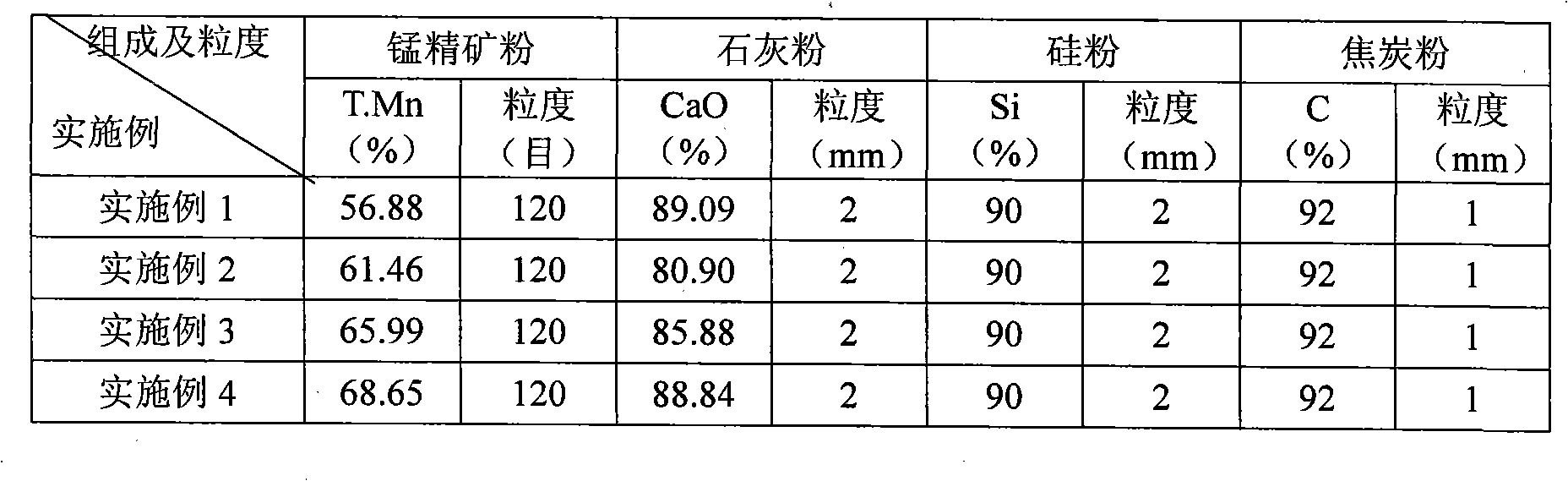

[0023] The present invention takes the preparation of four kinds of manganese-based fluxes for converter steelmaking with different composition contents as an example. When preparing the manganese-based fluxes in Examples 1 to 4 of Table 2, first prepare the raw material ratios given in Examples 1 to 4 in Table 3 according to its composition content, wherein the raw materials and reducing agent used in Production Examples 1 to 4 are composed And particle size should meet the requirements of Table 4. Fully stir various raw materials and reducing agents in the mixer; then lay the mixed raw materials on the belt sintering machine for firing. The manganese-based flux is crushed and sieved to produce the manganese-based flux corresponding to the components 1-4 of Example 2 in Table 2; the particle size of the finished product is 10-40mm, and the water content is controlled at ≤1.0% by weight.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com