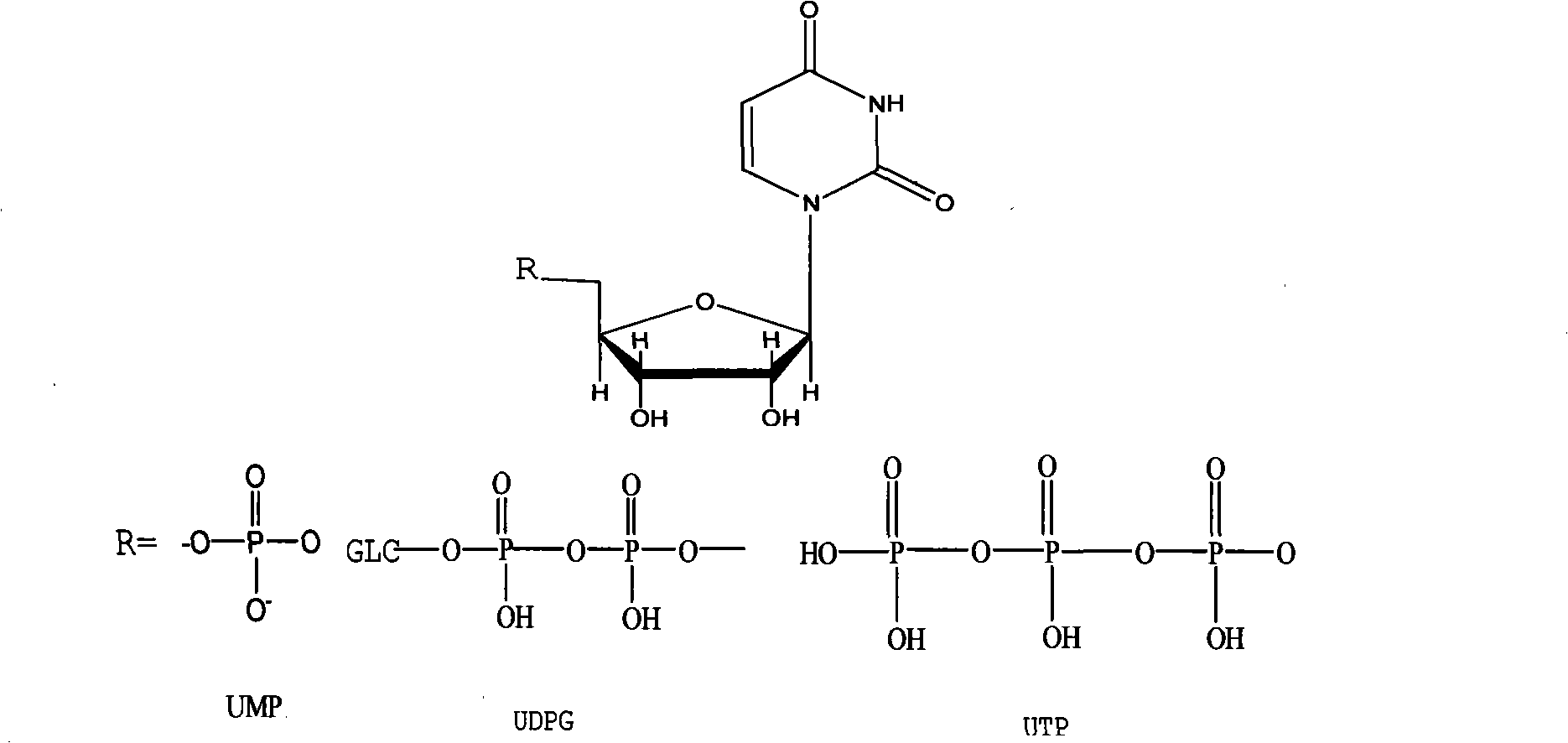

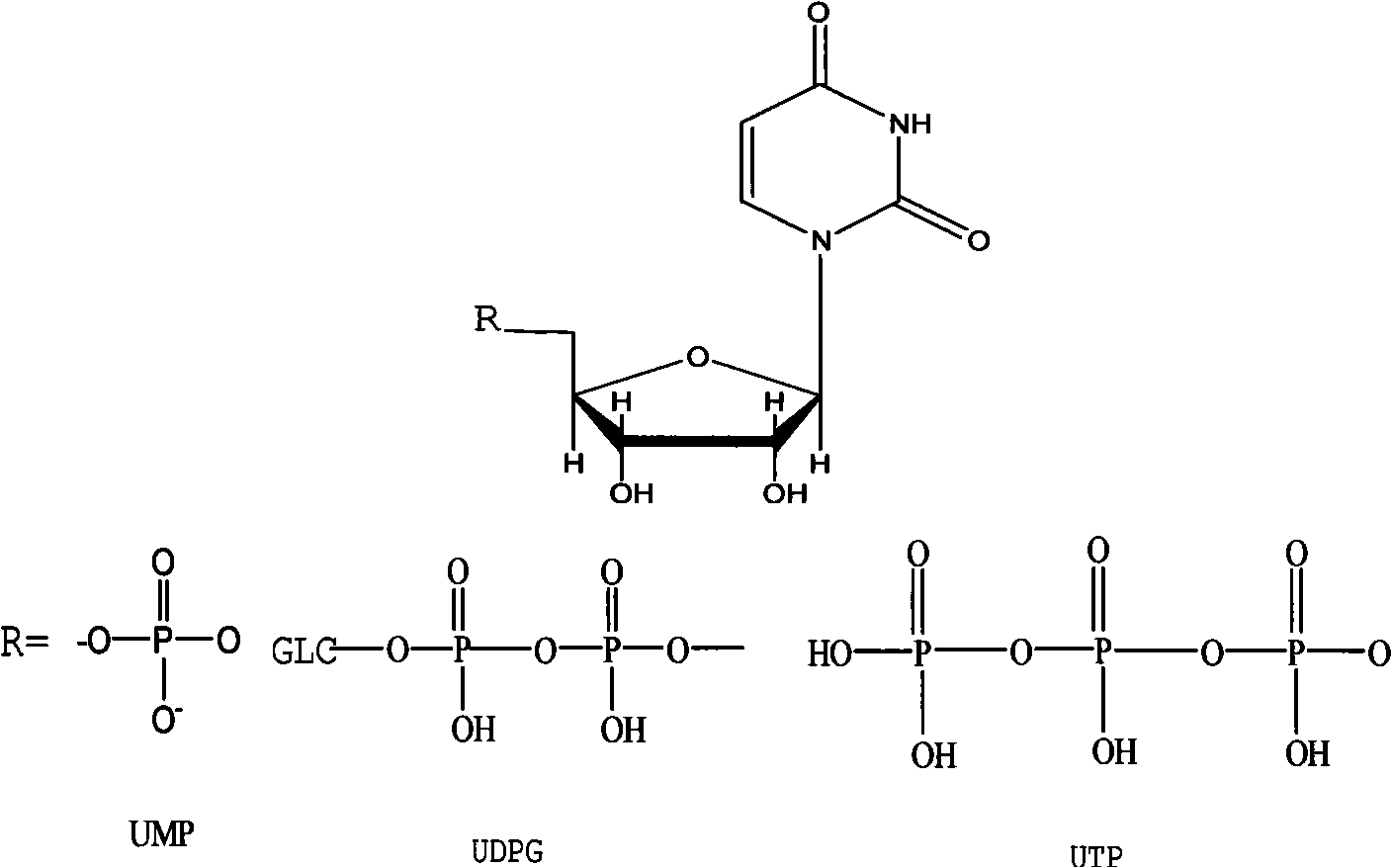

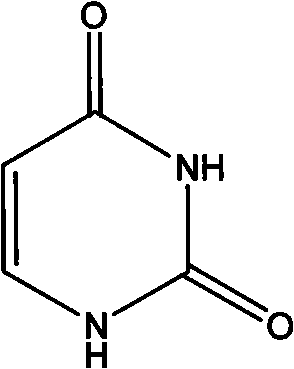

Method for catalyzing and synthesizing uridine phosphinylidyne compound in an oriented way

A uridine phosphoryl compound, uridine technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effects of low production cost, enhanced enzyme activity, and simple reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Directed production of UMP using uridine.

[0046] In a reaction tank with a capacity of 15L, it is composed of 600mMol of uridine, 5Mol of glucose, 50mMol of magnesium sulfate, 2400g of Brevibacterium ammoniagenes, 20mMol of ammonium chloride, 300mMol of potassium chloride, 2.0Mol of sodium dihydrogen phosphate, 50ml of toluene and water. 10L of the reaction solution, the pH was adjusted to 7.0 with sodium hydroxide, the dissolved oxygen was controlled at 70%, and the temperature was 30°C. After 8 hours of reaction, the reaction was terminated, and the product was precipitated with perchloric acid, and the product was quantitatively analyzed by HPLC. The main product is UMP with a content of 457mMol (208g) and a yield of 76.1%. At this time, the content of UTP is 68.3mMol (33.1g) and the content of UDPG is 24.6mMol (15g).

Embodiment 2

[0047] Example 2: Directed production of UTP using uridine.

[0048] In a reaction tank with a capacity of 15L, it is composed of 600mMol of uridine, 5Mol of glucose, 50mMol of magnesium sulfate, 2400g of Brevibacterium ammoniagenes, 20mMol of ammonium chloride, 300mMol of potassium chloride, 2.0Mol of sodium dihydrogen phosphate, 50ml of toluene and water. 10L of the reaction solution, adjust the pH to 7.0 with sodium hydroxide, control the dissolved oxygen at 70%, and the temperature at 30°C. After 8 hours of reaction, adjust the dissolved oxygen to 25%, adjust the temperature to 37°C, continue the reaction for 6 hours, and end Reaction, precipitation with perchloric acid, carry out quantitative analysis to product with HPLC, main product is UTP in the conversion liquid, and its content is 398mMol (193g), and yield is 66.3%, and UMP content is now 57.3mMol (18.6g), The UDPG content was 80.2 mMol (48.9 g).

Embodiment 3

[0049] Example 3: Directed production of UDPG using uridine.

[0050] In a reaction tank with a capacity of 15L, it is composed of 600mMol of uridine, 5Mol of glucose, 50mMol of magnesium sulfate, 2400g of Brevibacterium ammoniagenes, 20mMol of ammonium chloride, 300mMol of potassium chloride, 2.0Mol of sodium dihydrogen phosphate, 50ml of toluene and water. 10L of the reaction solution, the pH was adjusted to 7.0 with sodium hydroxide, the dissolved oxygen was controlled at 70%, and the temperature was 30°C. After 8 hours of reaction, the dissolved oxygen was adjusted to 25%, and the temperature was adjusted to 37°C. After continuing the reaction for 6 hours, Dissolved oxygen is adjusted to 5%, temperature is adjusted to 25 ℃, continue to react for 4 hours, finish reaction, precipitate with perchloric acid, carry out quantitative analysis to product with HPLC, main product is UDPG in the conversion liquid, and its content is 361mMol (220g) , the yield was 60.2%. At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com