Carbonated complex oxides and method for making the same

A compound, carbon film technology, used in chemical instruments and methods, phosphorus compounds, electrode heat treatment, etc., can solve problems such as quality degradation, product vicious changes, battery cyclability or harmful charge potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

[0081] C-LiFePO 4 Synthesis

[0082] Preparation containing stoichiometric amounts of FePO 4 ·(H 2 O) 2 (1mol, purchased from Budenheim, grade E53-81) and Li 2 CO 3 (1mol, purchased from Limtech, purity 99.9%), and a mixture of 5% polyethylene block polyethylene glycol (purchased from Aldrich) containing 50% ethylene oxide, and it was added to isopropanol, mixed About 10h, then remove the solvent. In the material thus obtained, the polymer holds the phosphate and carbonate particles together.

[0083]The mixture was treated under nitrogen flow at 700 °C for 2 h to obtain the battery-grade material C-LiFePO 4 , followed by vacuum drying at 100 °C, and the final material was stored in a glove box under an argon atmosphere with a dew point of -90 °C.

[0084] The specific surface area of the material is 13.6m 2 / g, the carbon content is 1.8% by weight.

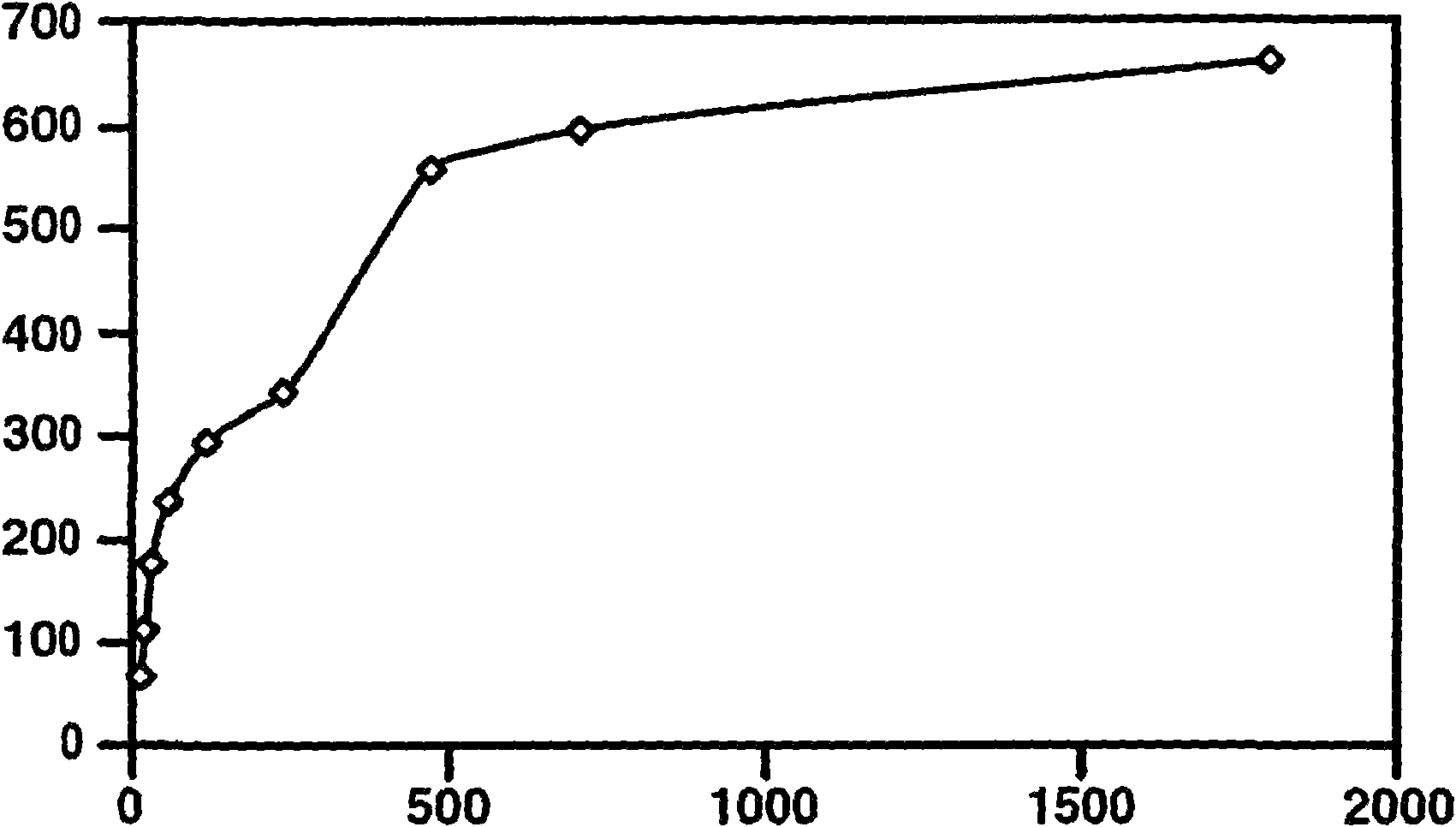

[0085] Ground material C-LiFePO 4 sensitivity to water

[0086] The material obtained was jet-milled under compre...

Embodiment 1b

[0091] C-LiFe 0.5 mn 0.5 PO 4 Synthesis

[0092] By adding a stoichiometric amount of the precursor LiH 2 PO 4 , FeC 2 o 4 2H 2 O and (CH 3 COO) 2 Mn 4H 2 O mixed to prepare the compound LiFe 0.5 mn 0.5 PO 4 . The mixture was subsequently triturated in heptane, then dried in air and gradually heated to 40 °C to decompose the acetate and oxalate groups. The temperature was maintained for 8 hours. During the treatment, iron (II) is oxidized to iron (III).

[0093] The mixture was then ground again in an acetone solution containing 39.7% by weight of acetyl groups and 5% of cellulose acetate (carbon precursor) relative to the mixture.

[0094] After drying, the mixture was heated to 700°C in a tube furnace at a rate of 6°C / min. The temperature was maintained for 1 hour, and then the sample was cooled for 40 minutes, ie, the sample was cooled at a cooling rate of about 15° C. / minute. Keep the tube furnace under reducing gas flow (CO / CO 2 : 1 / 1).

[0095] In thi...

Embodiment 1c

[0099] C-LiFe 0.98 Mg 0.02 PO 4 Synthesis

[0100] Preparation of compound LiFe by melting method 0.98 Mg 0.02 PO 4 . Mix compound Fe in a molar ratio of 0.49 / 0.5 / 0.98 / 0.02 2 o 3 , Li 2 CO 3 , NH 4 ) 2 HPO 4 and MgHPO 4 , the mixture was then heated to 980° C. under argon in a graphite crucible, held at this temperature for 1 hour to melt it, and then cooled to about 50° C. within 3 hours.

[0101] The thus obtained compound LiFe was then 0.98 Mg 0.02 PO 4 at 90cm 3 12 g of zirconia beads with a diameter of 20 mm in isopropanol for 10 minutes and then 440 g of zirconia beads with a diameter of 3 mm for 90 minutes to obtain a powder with an average particle size of 1.12 μm.

[0102] The LiFe obtained after grinding 0.98 Mg 0.02 PO 4 The powder was mixed with 7% by weight of cellulose acetate, then dried and treated at 700 °C under argon for 1 hour to obtain carbon deposits containing 1.32% by weight and a specific surface area of 19.2 m 2 / g material C-L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com