Nanometre-sized fibre liquid separation composite film and preparation method thereof

A nanofiber, liquid separation technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of large-scale coating of electrospinning nanofiber non-woven fabrics, difficult to promote and apply, etc. , to achieve the effect of easy spinning parameter control, simple and easy control of the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) 13.0 g of polyacrylonitrile (PAN) was dissolved in 87 g of N,N-dimethylacetamide (DMAC) solvent to obtain the first transparent and uniform electrospinning solution;

[0034] (2) Dissolve 4.0 g of polyvinylidene fluoride (PVDF) in 92 g of a mixed solvent of N,N-dimethylformamide (DMF) / acetone, N-dimethylformamide (DMF) / acetone=2 / 8, to obtain a transparent and uniform second electrospinning solution;

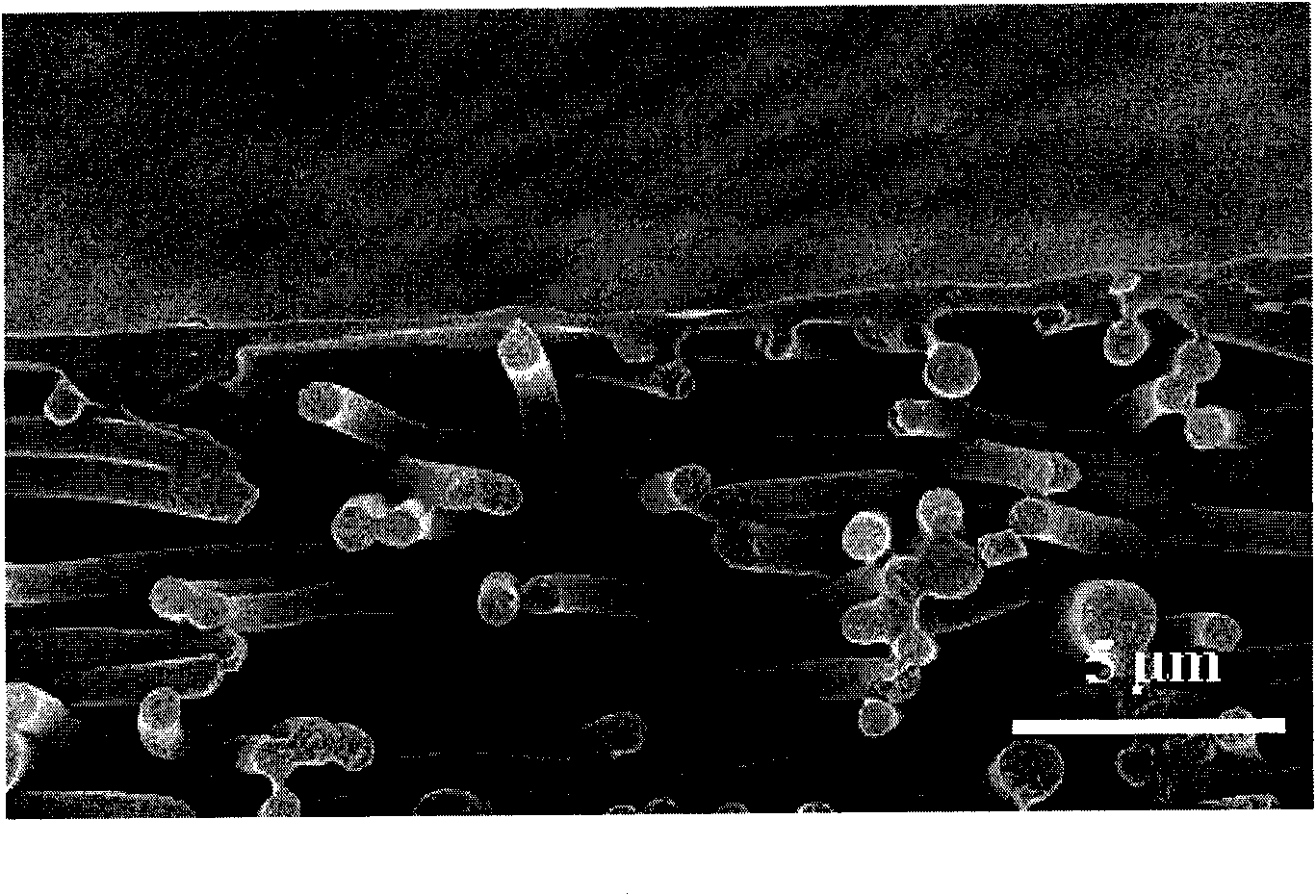

[0035](3) Add the first spinning stock solution into the container, extrude under the control of a micro-injection pump, the nozzle is connected to a high-voltage positive electrode, the electrospinning parameters are controlled at a voltage of 16kv, the nozzle aperture is 0.5mm, the solution flow rate is 30μl / min, and the ambient temperature Electrospinning was performed at 25° C. and a relative air humidity of 75%. The obtained PAN electrospun nanofibers had an average diameter of 1.2 μm and a deposition thickness of 500 μm. The porosity is 72%.

[0036] (4) Add t...

Embodiment 2

[0044] (1) 19.0 g of polysulfone (PSU) was dissolved in 81 g of N,N-dimethylformamide (DMF) solvent to obtain the first transparent and uniform electrospinning solution;

[0045] (2) 7.0 g of polyvinyl alcohol (PVA) was dissolved in 93 g of deionized water to obtain a transparent and uniform second electrospinning solution;

[0046] (3) Add the first spinning stock solution into the container, extrude under the control of a micro-injection pump, connect the nozzle to a high-voltage positive electrode, and control the electrospinning parameters at a voltage of 10kv, a nozzle aperture of 1mm, a solution flow rate of 40μl / min, and an ambient temperature of 55 ℃, air relative humidity 45%, carry out electrospinning, the average diameter of the obtained PAN electrospun nanofiber is 2 μm, deposition thickness is 250 μm, porosity is 86%;

[0047] (4) Add the second spinning stock solution into the container, extrude under the control of a micro-injection pump, connect the nozzle to a...

Embodiment 3

[0051] (1) 24g of polyethersulfone (PES) was dissolved in 76g of N,N-dimethylformacetamide (DMAC) solvent to obtain the first transparent and uniform electrospinning solution;

[0052] (2) Dissolving 12.0 g of polyamic acid in 88 g of N,N-dimethylformamide (DMF) solvent to obtain a transparent and uniform second electrospinning solution;

[0053] (3) Add the first spinning stock solution into the container, extrude under the control of a micro-injection pump, the nozzle is connected to a high-voltage positive electrode, the electrospinning parameters are controlled at a voltage of 18kv, the nozzle aperture is 1.8mm, the solution flow rate is 35μl / min, and the ambient temperature Electrospinning was performed at 25° C. and relative air humidity of 45%. The obtained PAN electrospun nanofibers had an average diameter of 500 nm and a deposition thickness of 70 μm. Porosity 92%

[0054] (4) Add the second spinning stock solution into the container, extrude under the control of a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com