High strength heat-resisting hypereutectic aluminium-silicon alloy and preparation method thereof

An aluminum-silicon alloy and hypereutectic technology, which is applied in the field of metallurgy, can solve the problems of poor heat resistance and low tensile strength, and achieve the effects of improving heat resistance, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

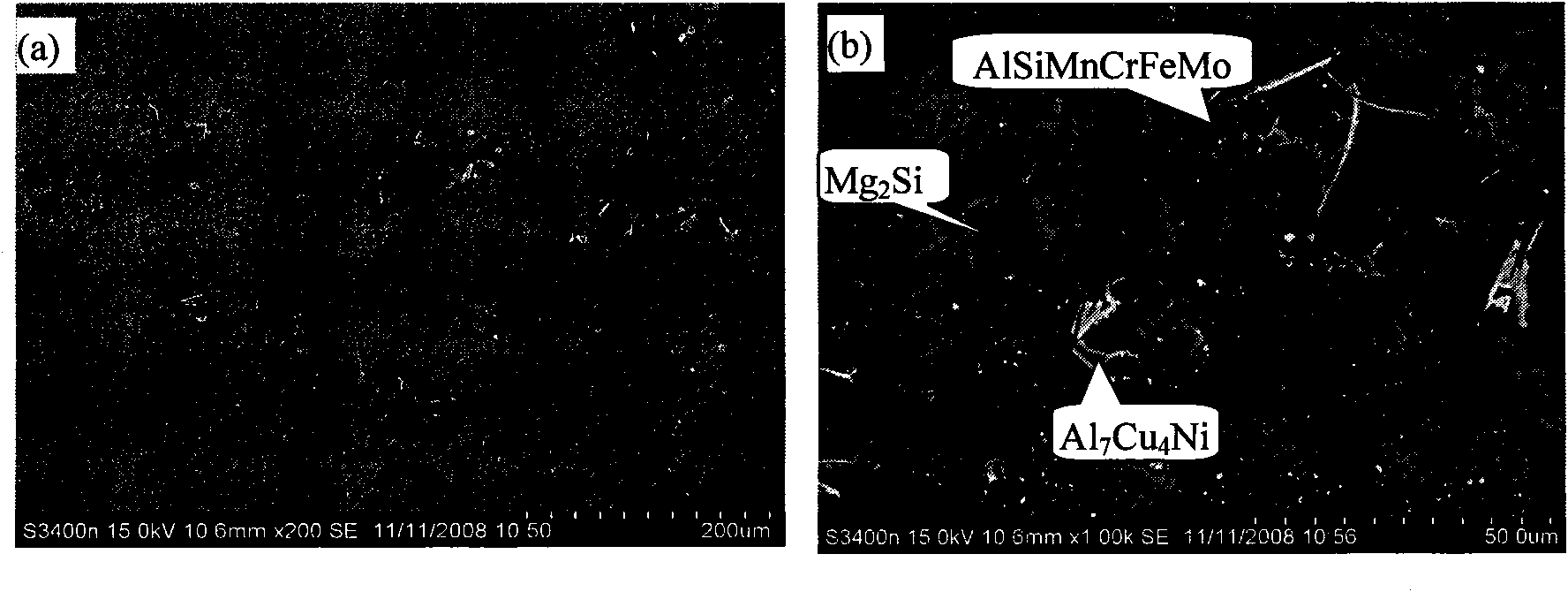

Image

Examples

Embodiment 1

[0021] Heat metal aluminum to 720°C to become liquid, add aluminum-silicon alloy, aluminum-copper alloy, aluminum-nickel alloy, aluminum-chromium alloy, aluminum-iron alloy, aluminum-manganese alloy, aluminum-zirconium alloy, aluminum rare-earth alloy, aluminum-molybdenum alloy, of which rare earth components account for 10% of the weight of the aluminum rare earth alloy, the rare earth composition is 56% by weight of cerium, 24% of lanthanum, 4% of praseodymium, and 16% of niobium; heat preservation at 720°C until all metals are melted into a liquid state, the first time Add aluminum refining agent, keep warm at 720°C for 15 minutes, then skim the slag, press the metal magnesium wrapped in aluminum foil into the metal molten pool with a metal cover, stir until the metal magnesium is completely melted, and keep warm at 720°C for 15 minutes; Add the modifier copper-phosphorus alloy into the pool, stir until the modifier is completely melted, and keep warm at 720°C for 40 minutes...

Embodiment 2

[0031]Heat metal aluminum to 820°C to become liquid, add aluminum-silicon alloy, aluminum-copper alloy, aluminum-nickel alloy, aluminum-chromium alloy, aluminum-iron alloy, aluminum-manganese alloy, aluminum-molybdenum alloy, and keep warm at 820°C until all the metal melts into a liquid state , add aluminum refining agent for the first time, keep warm at 820°C for 10 minutes, then skim the slag, press the metal magnesium wrapped in aluminum foil into the metal molten pool with a metal cover, stir until the metal magnesium is completely melted, and keep warm at 750°C 10 minutes; add the modifier copper-phosphorus alloy into the molten pool, stir until the modifier is completely melted, and keep warm at 750°C for 35 minutes. Add the aluminum refining agent for the second time, keep the temperature at 750°C for 15 minutes, then skim off the slag, and then let it stand for 9 minutes. Among them, the composition of the modifier copper-phosphorus alloy is 8% phosphorus by weight pe...

Embodiment 3

[0035] Heat metal aluminum to 780°C to become liquid, add silicon, copper, nickel, iron, manganese, zirconium, chromium and molybdenum, add aluminum rare earth alloy, and then add metal aluminum to cover the above metal or alloy, wherein the aluminum rare earth alloy contains The rare earth composition accounts for 10% of the weight of the aluminum rare earth alloy, and the rare earth composition is 56% by weight of cerium, 24% of lanthanum, 4% of praseodymium, and 16% of niobium; it is kept at 780°C until all the metals are melted into a liquid state , add aluminum refining agent for the first time, keep warm at 780°C for 5 minutes, then skim off the slag, press the metal magnesium wrapped in aluminum foil into the metal molten pool with a metal cover, stir until the metal magnesium is completely melted, and keep warm at 780°C 5min; add the modifier copper-phosphorus alloy into the molten pool, stir until the modifier is completely melted, and keep warm at 780°C for 30min. Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap