Silica doped modified insoluble iridium oxide anode and preparation method thereof

A technology of iridium dioxide and silicon dioxide, used in electrodes, solid-state chemical plating, coatings, etc., can solve problems such as chemical stability to be improved, and achieve fine grain size, reduced preparation and use costs, and oxygen evolution electroplating. High catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

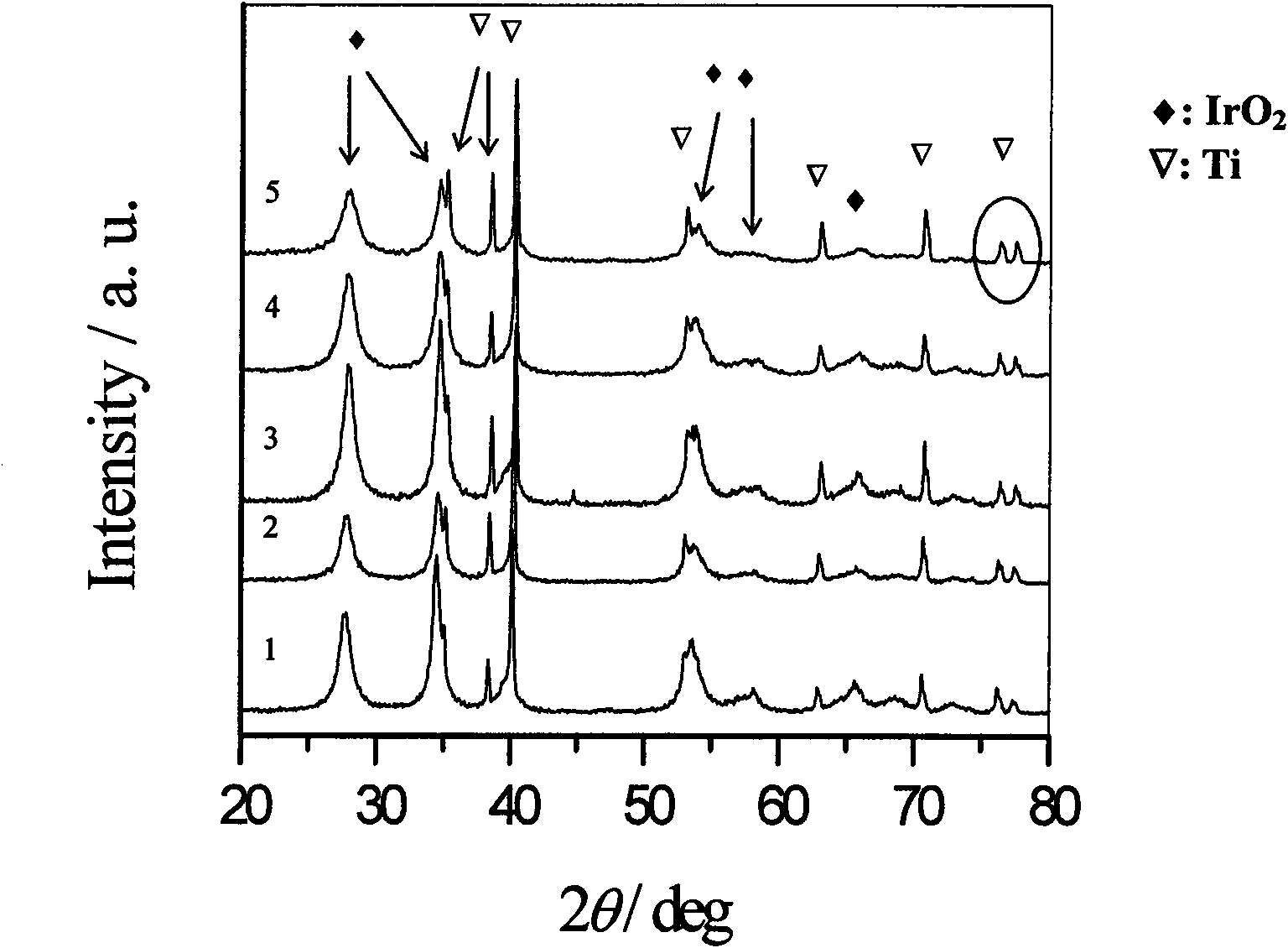

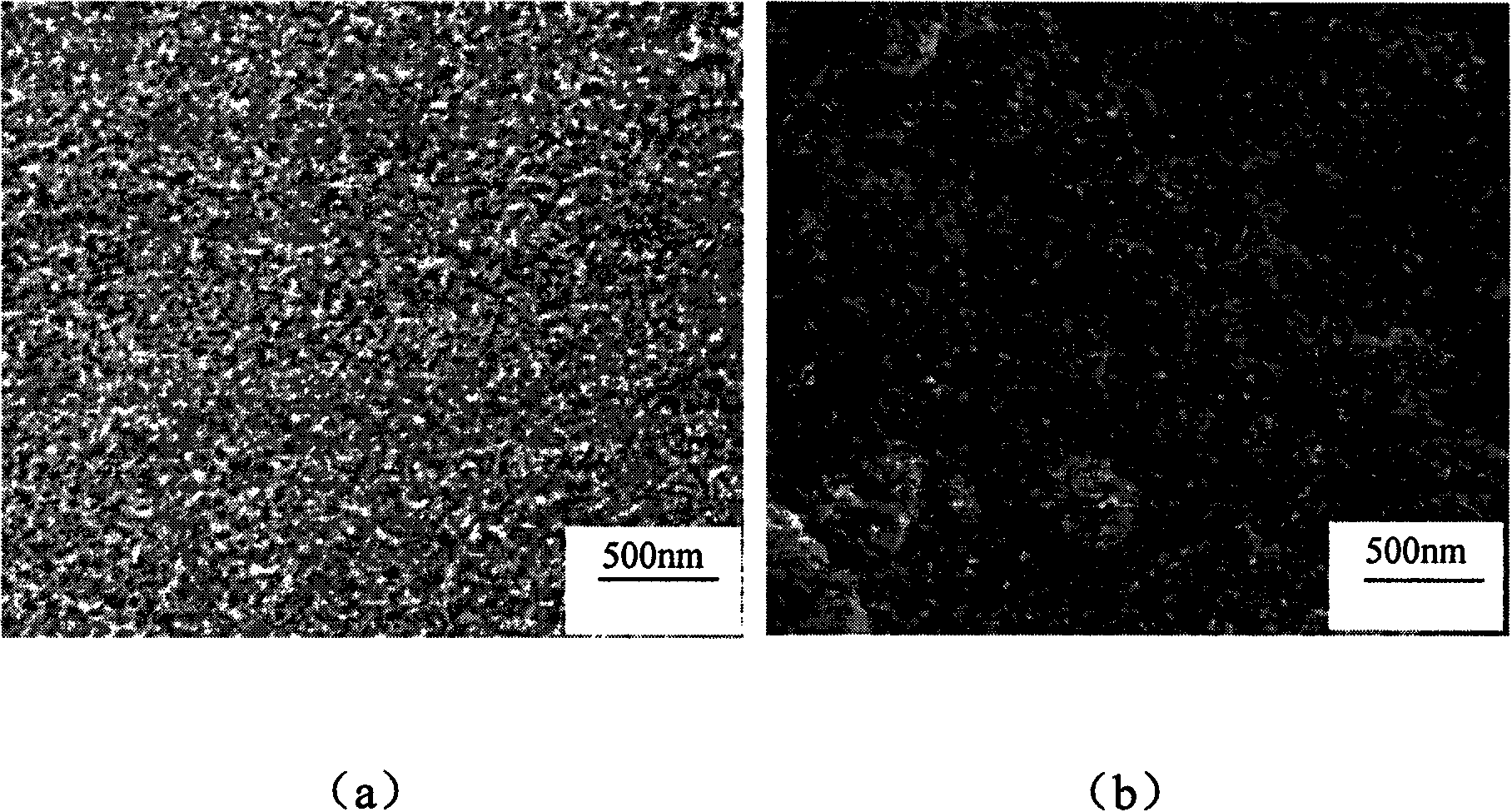

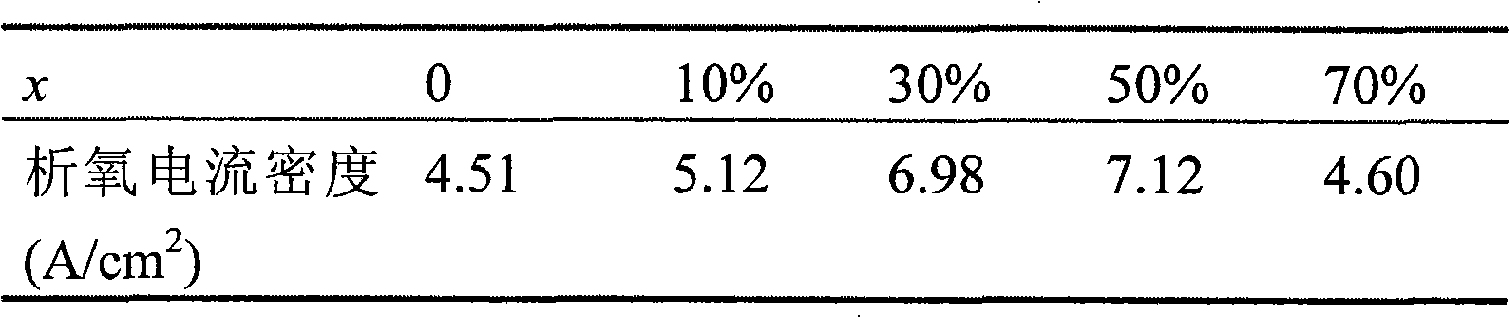

Embodiment 1

[0031]The 90mm×18mm titanium substrate after sand blasting was washed with alkali at 60-80°C for 30 minutes to remove oil, then soaked in boiling oxalic acid solution with a mass fraction of 10% for 30 minutes, and finally ultrasonically cleaned in deionized water and blown. Dry and set aside. Weigh a certain amount of gas-phase SiO with an average diameter of ~10 nm 2 Dissolve the powder in a 1:1 ethanol-isopropanol solvent, weigh a certain amount of H 2 IrCl 6 ·6H 2 O was dissolved in a 1:1 ethanol / isopropanol solvent, and then the two solutions were mixed with each other, and then ultrasonically mixed for 10 min to prepare a precursor coating solution. The above coating solution was coated on the pretreated titanium substrate, dried at 90°C for 10 minutes, sintered at 500°C for 10 minutes, then taken out and cooled to room temperature. Coating, drying and sintering are carried out again, and this cycle is repeated 10 times, and finally sintering at 500° C. for 1 hour. ...

Embodiment 2

[0038] Wash the borax-treated titanium substrate of 90mm×18mm with alkali at 60-80°C for 30 minutes to remove oil, then soak it in boiling oxalic acid solution with a mass fraction of 10% for 30 minutes, and finally ultrasonically clean it in deionized water and dry it for later use . Take by weighing a certain amount of methyltrimethoxysilane monomer (structural formula is: CH 3 -Si-(OCH 3 ) 3 ) was dissolved in 1:1 ethanol isopropanol solvent, weighed a certain amount of H 2 IrCl 6 ·6H 2 O was dissolved in a 1:1 ethanol-isopropanol solvent, and then the two solutions were mixed with each other, and then ultrasonically mixed for 10 minutes to prepare a precursor coating solution. The above coating solution was coated on the pretreated titanium substrate, dried at 90°C for 10 minutes, sintered at 500°C for 10 minutes, then taken out and cooled to room temperature. Coating, drying and sintering are carried out again, and this cycle is repeated 10 times, and finally sinter...

Embodiment 3

[0045] Wash the borax-treated titanium substrate of 90mm×18mm with alkali at 60-80°C for 30 minutes to remove oil, then soak it in boiling oxalic acid solution with a mass fraction of 10% for 30 minutes, and finally ultrasonically clean it in deionized water and dry it for later use . A certain amount of methyltriethoxysilane monomer was weighed and dissolved in ethanol, and diluted ammonia solution was slowly added dropwise, left standing overnight, and filtered to obtain silica sol. Dissolve this silica sol in 1:1 ethanol isopropanol, and weigh a certain amount of H 2 IrCl 6 ·6H 2 O was dissolved in a 1:1 ethanol-isopropanol solvent, and then the two solutions were mixed with each other, and then ultrasonically mixed for 10 minutes to prepare a precursor coating solution. The above coating solution was coated on the pretreated titanium substrate, dried at 100°C for 10 minutes, sintered at 500°C for 10 minutes, then taken out and cooled to room temperature. Coating, dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com