Lithium ion battery porous LiMn2O4 cathode material and the preparation method thereof

A technology of lithium ion battery and positive electrode material, applied in the field of lithium ion battery LiMn2O4 positive electrode material and its preparation, can solve the problems of high cost and difficulty in mass production, and achieve the effects of high specific capacity, stable cycle performance and good rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

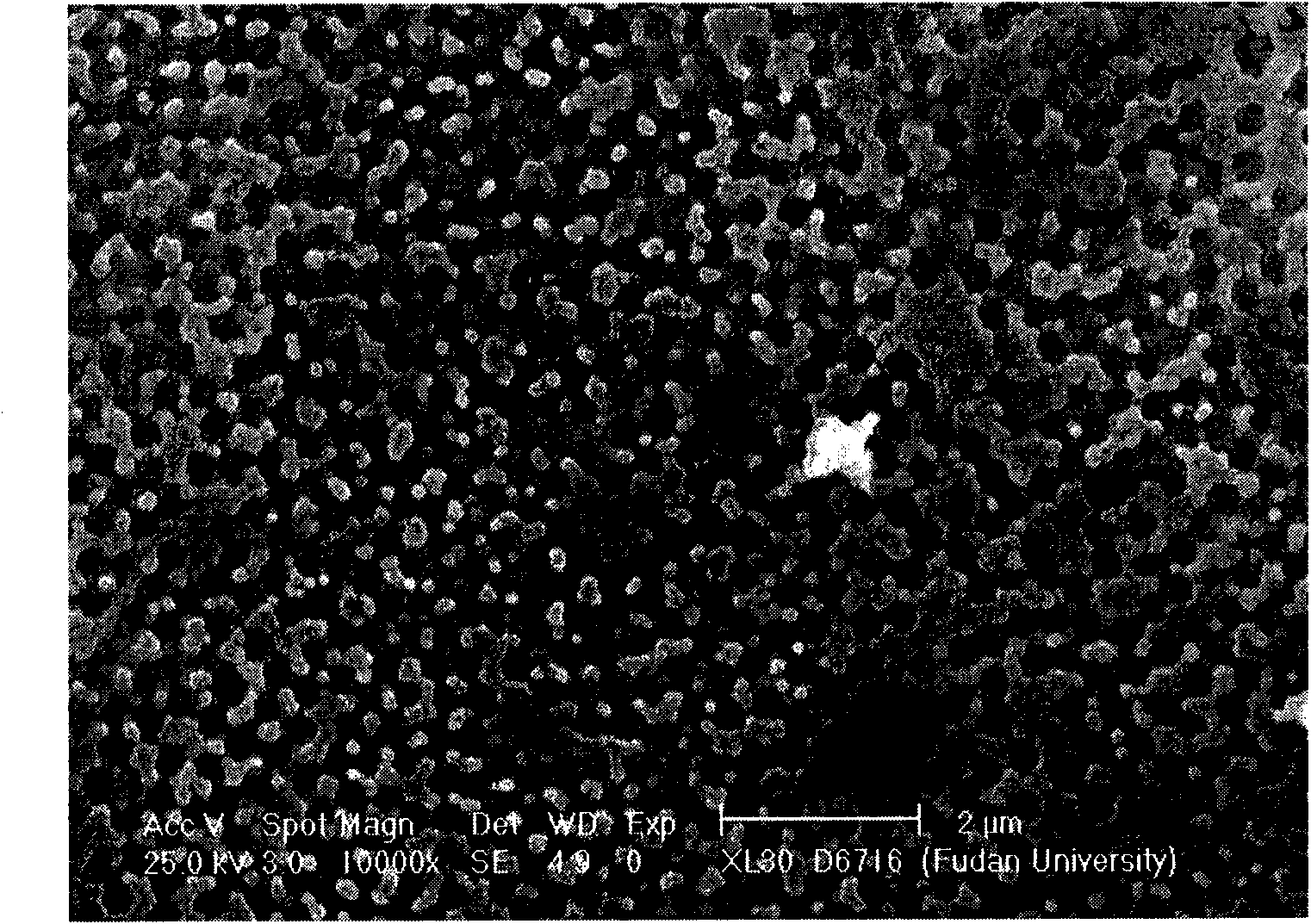

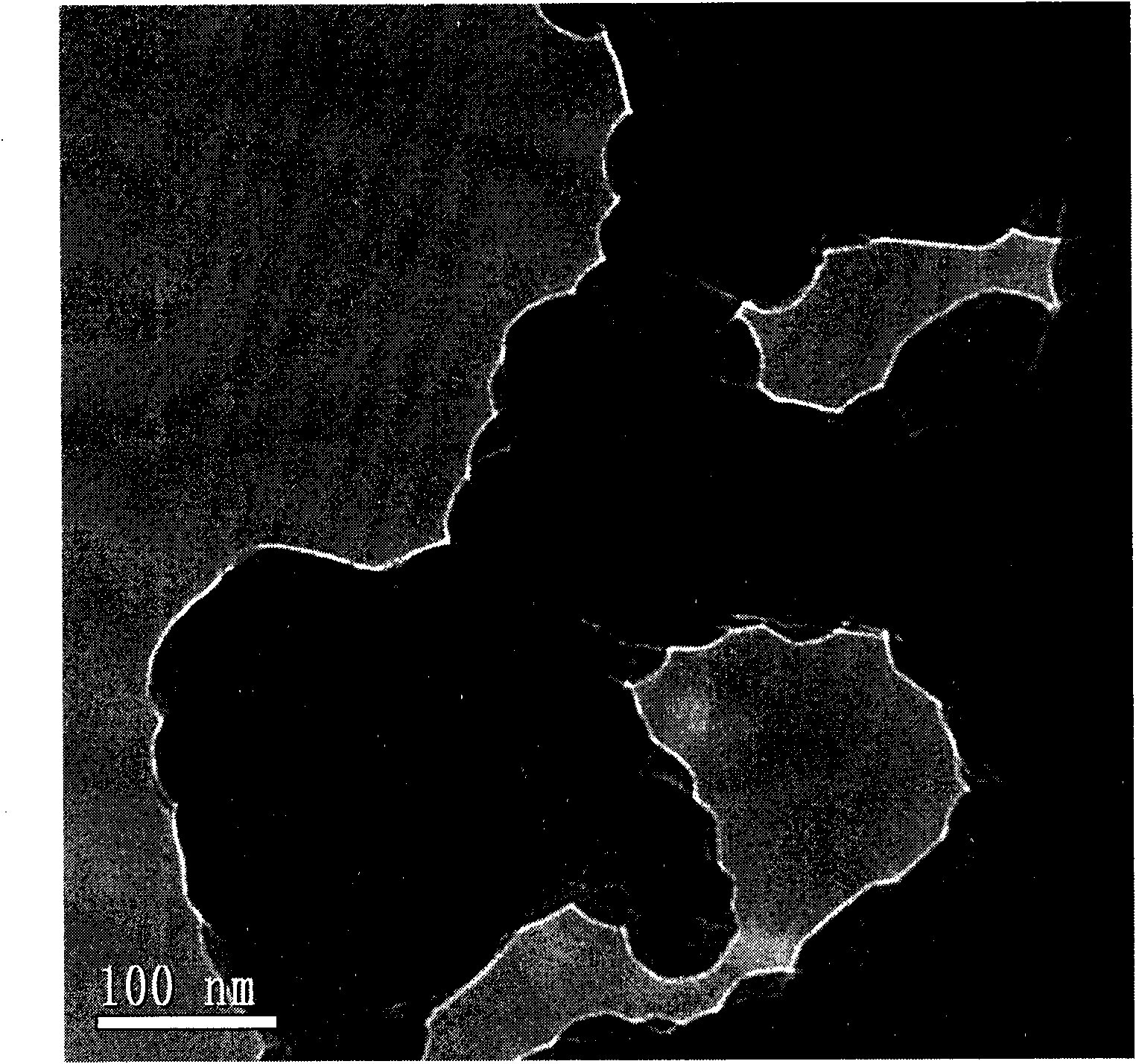

[0026] First, manganese nitrate and lithium nitrate in stoichiometric ratio (i.e. manganese nitrate: lithium nitrate molar ratio is 2:1) are dissolved in ethanol, and polystyrene particles with a particle diameter of 100nm are added thereto, stirred, and after solvent removal, the obtained powder Slowly heat up to 700°C and calcined for 3 hours, cool to room temperature, remove and grind, and sieve to obtain porous LiMn 2 o 4 . Its X-ray diagram is attached Figure 4 (b), relative to the X-ray pattern of Comparative Example 1, the X-ray pattern of Example 1 shows the porous LiMn 2 o 4 Good spinel structure with a small amount of Mn 2 o 3 Impure, SEM, TEM are shown in the attached figure 1 with 2 , indicating a porous structure.

Embodiment 2

[0028] First, dissolve manganese nitrate and lithium nitrate in stoichiometric ratio (i.e. manganese nitrate: lithium nitrate molar ratio is 2:1) in the mixture of ethanol and water, add polystyrene particles with a particle diameter of 10nm therein, stir, remove After the solvent is removed, the obtained powder is slowly heated to 500°C for calcination for 3 hours, cooled to room temperature, removed for grinding, and sieved to obtain porous LiMn 2 o 4 . Its X-ray image is shown in Figure 4 (a), with respect to the X-ray pattern of comparative example 1, the X-ray pattern of embodiment 2 has shown hole shape LiMn equally 2 o 4 Good spinel structure, but its strength is weakened relative to Example 1, and contains a small amount of Mn 2 o 3 impurity.

Embodiment 3

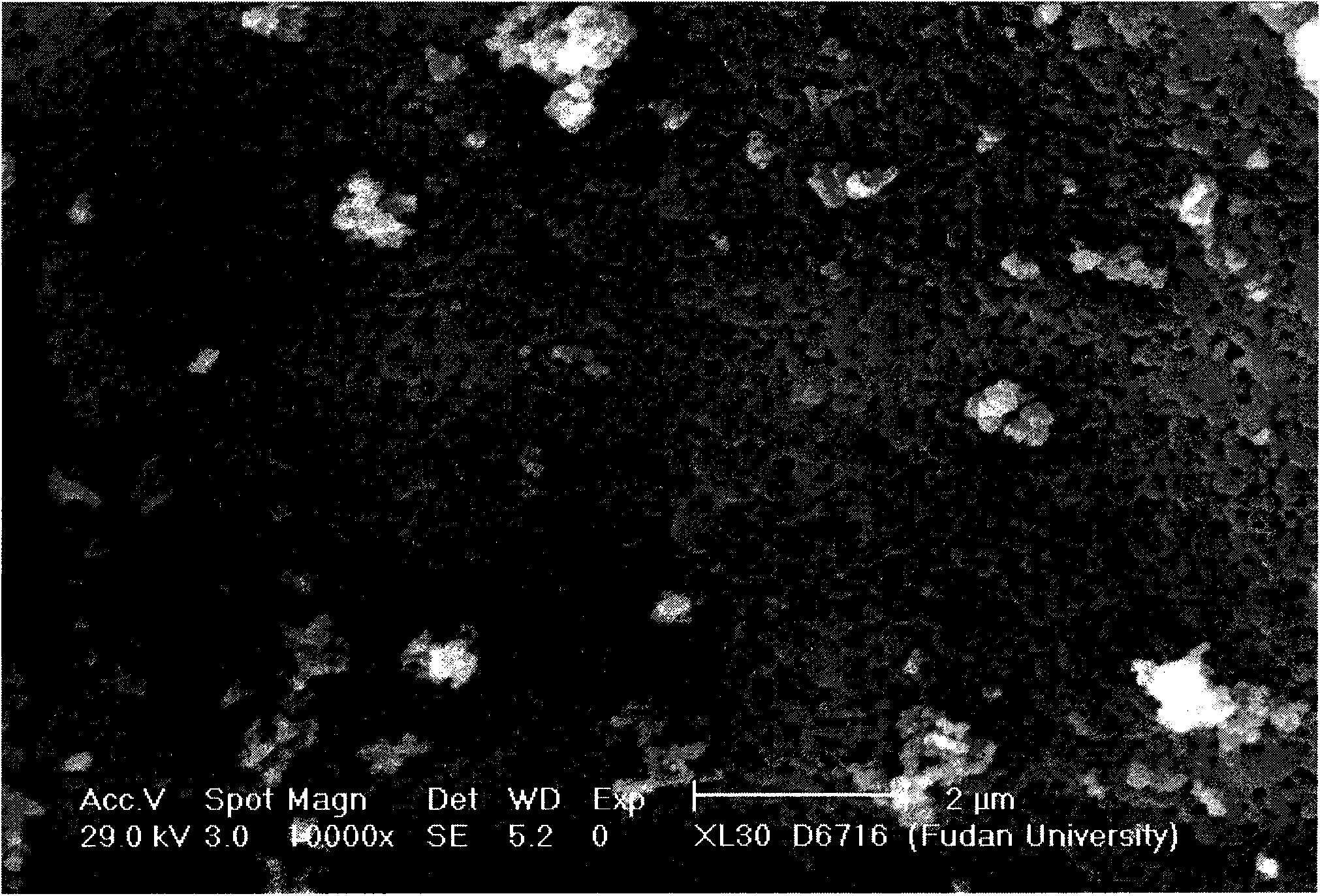

[0030] First, dissolve the stoichiometric manganese acetate and lithium acetate in water, and make the concentration of the two acetates reach 0.3M, then add polymethyl methacrylate with a particle size of 500nm to the solution, stir, and finally remove the solvent , after grinding, calcined at 500°C for 3 hours, cooled to room temperature, removed the grinding, and sieved to obtain LiMn 2 o 4 . Its scanning electron micrograph shows that it is also a hole-like structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com