Hydrophobic polymer material surface hydrophilicity improving method

A hydrophobic polymer and hydrophilic technology, which is applied in the field of improving the surface hydrophilicity of hydrophobic polymer materials, can solve the problem that the surface hydrophilicity of the material cannot be lasting, and achieves reliable treatment effect, improved surface hydrophilicity and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

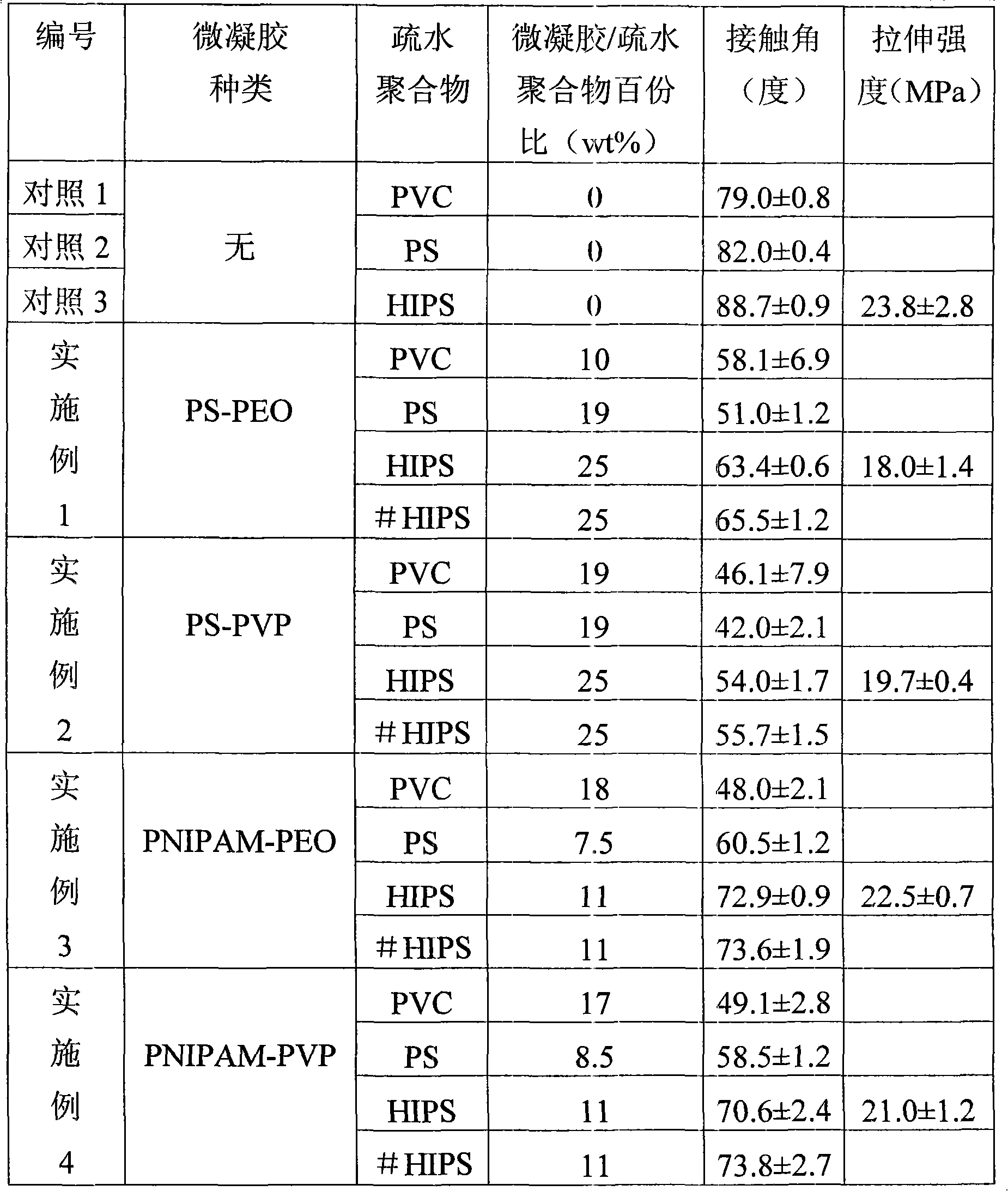

Embodiment 1

[0030] 100.0g deionized water, 5.00g styrene (St) monomer, 0.05g crosslinking agent divinylbenzene (DVB) and 1.00g mass fraction are polyethylene glycol methacrylate (M W =1000) macromonomer aqueous solution was added in the reactor, stirred and nitrogen exhausted. Raise the temperature to 60°C, add 2 mL of an aqueous solution of potassium persulfate (KPS) (containing 0.10 g KPS) as an initiator, and react for 12 h under the condition of stirring and blowing nitrogen. After the reaction is finished, the product is purified by dialysis through a dialysis membrane (MWCO=14000), and then freeze-dried to obtain a dry PS-PEO microgel with a non-thermosensitive core.

[0031] Prepare 10wt% PVC / THF solution and 10wt% PS / THF solution with tetrahydrofuran (THF) as solvent; add 0.04g of PS-PEO dry microgel into 15mLTHF, and disperse by ultrasonic for 30 minutes to obtain PS-PEO / THF dispersion. Mix 4mL PS-PEO / THF dispersion with 1mL PVC / THF solution and oscillate ultrasonically for 30...

Embodiment 2

[0035]With 100.0g deionized water, 2.50g St monomer, 0.03g DVB and 2.00g 50wt% polyvinylpyrrolidone (PVP) macromolecular monomer aqueous solution (M W =2000) into the reactor, stirred and exhausted with nitrogen. The temperature was raised to 60° C., 1 mL of KPS aqueous solution (containing 0.13 g of KPS) was added, and the reaction was carried out for 36 h under the conditions of stirring and nitrogen exhaust. After the reaction is completed, the product is purified by dialysis through a dialysis membrane (MWCO=14000), and then freeze-dried to obtain a PS-PVP microgel with a non-thermosensitive core.

[0036] The preparation of PVC / THF solution and PS / THF solution is as shown in embodiment example 1. Add 0.04 g of PS-PVP dry microgel with non-thermosensitive core into 15 mL THF, and disperse by ultrasonic for 30 minutes to obtain PS-PVP / THF dispersion liquid. Mix 3.5mL PS-PVP / THF dispersion with 0.5mL PVC / THF solution, and ultrasonically vibrate for 30 minutes to obtain a m...

Embodiment 3

[0040] 250g of deionized water, 2.00g of isopropylacrylamide (NIPAM) monomer, 0.05g of crosslinking agent N, N'-methylenebisacrylamide (BIS) and 8.70g of polyethylene glycol with a mass fraction of 50wt% Alcohol methacrylate (M W =5000) macromonomer aqueous solution was added into the reactor, stirred and nitrogen exhausted. The temperature was raised to 70°C, 10 mL of KPS aqueous solution (containing 0.60 g of KPS) was added, and the reaction was carried out for 24 h under stirring and nitrogen flow. After the reaction is finished, the product is refined by dialysis through a dialysis membrane (MWCO=14000), and then freeze-dried to obtain a PNIPAM-PEO microgel with a thermosensitive core in a dry state.

[0041] The preparation of PVC / THF solution and PS / THF solution is as shown in embodiment example 1. Add 0.15 g of PNIPAM-PEO dry microgel with thermosensitive core into 60 mL THF, and disperse by ultrasonic for 30 minutes to obtain PNIPAM-PEO / THF dispersion. Mix 3.5mL PNI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com