Preparation method of transparent yttrium hafnate ceramics

A technology of transparent ceramics and yttrium hafnate, which is applied in the field of preparation of yttrium hafnate transparent ceramics, can solve the problems of no yttrium hafnate transparent ceramics, etc., and achieve the effects of high sintering density, simple preparation process, easy operation and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

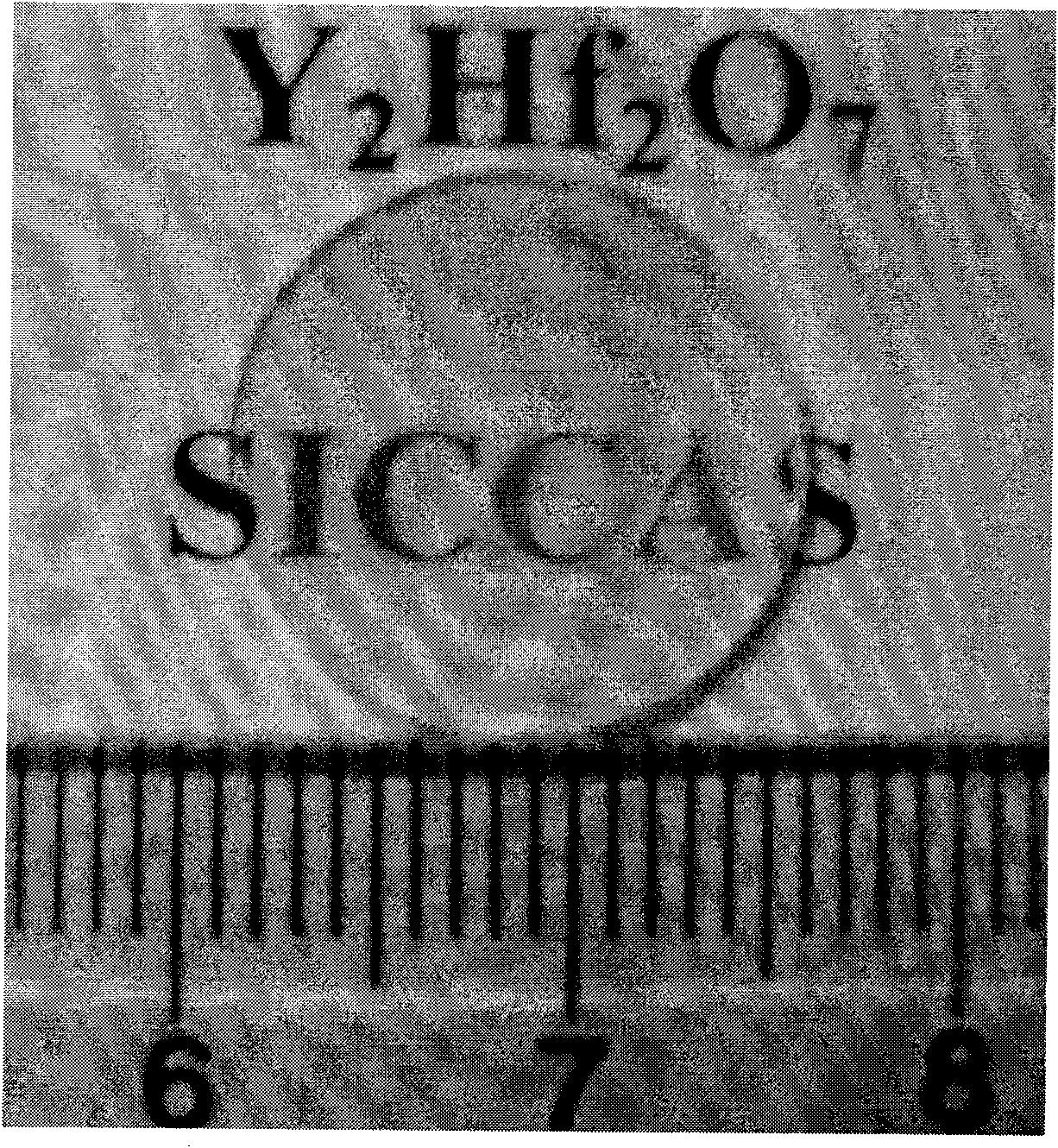

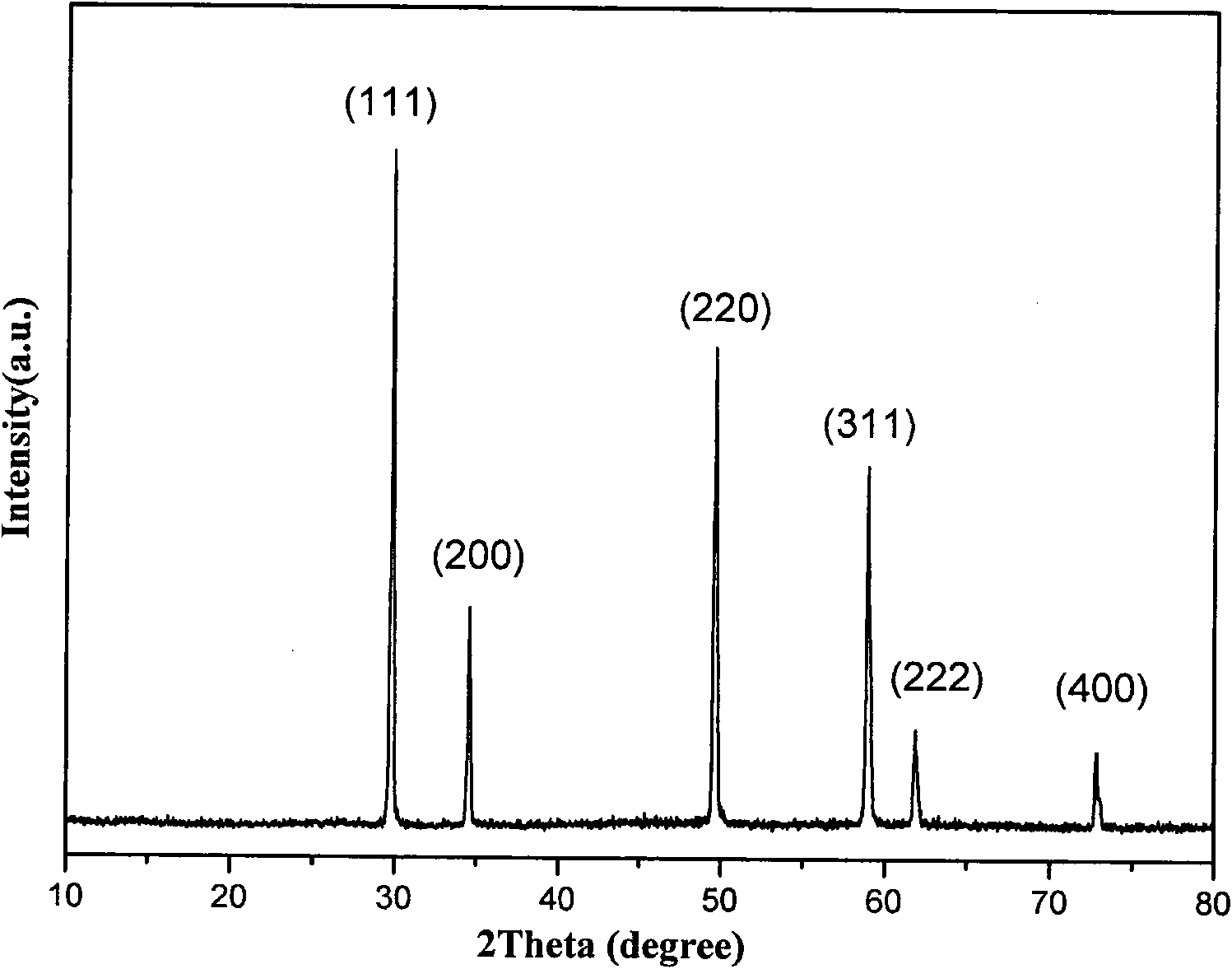

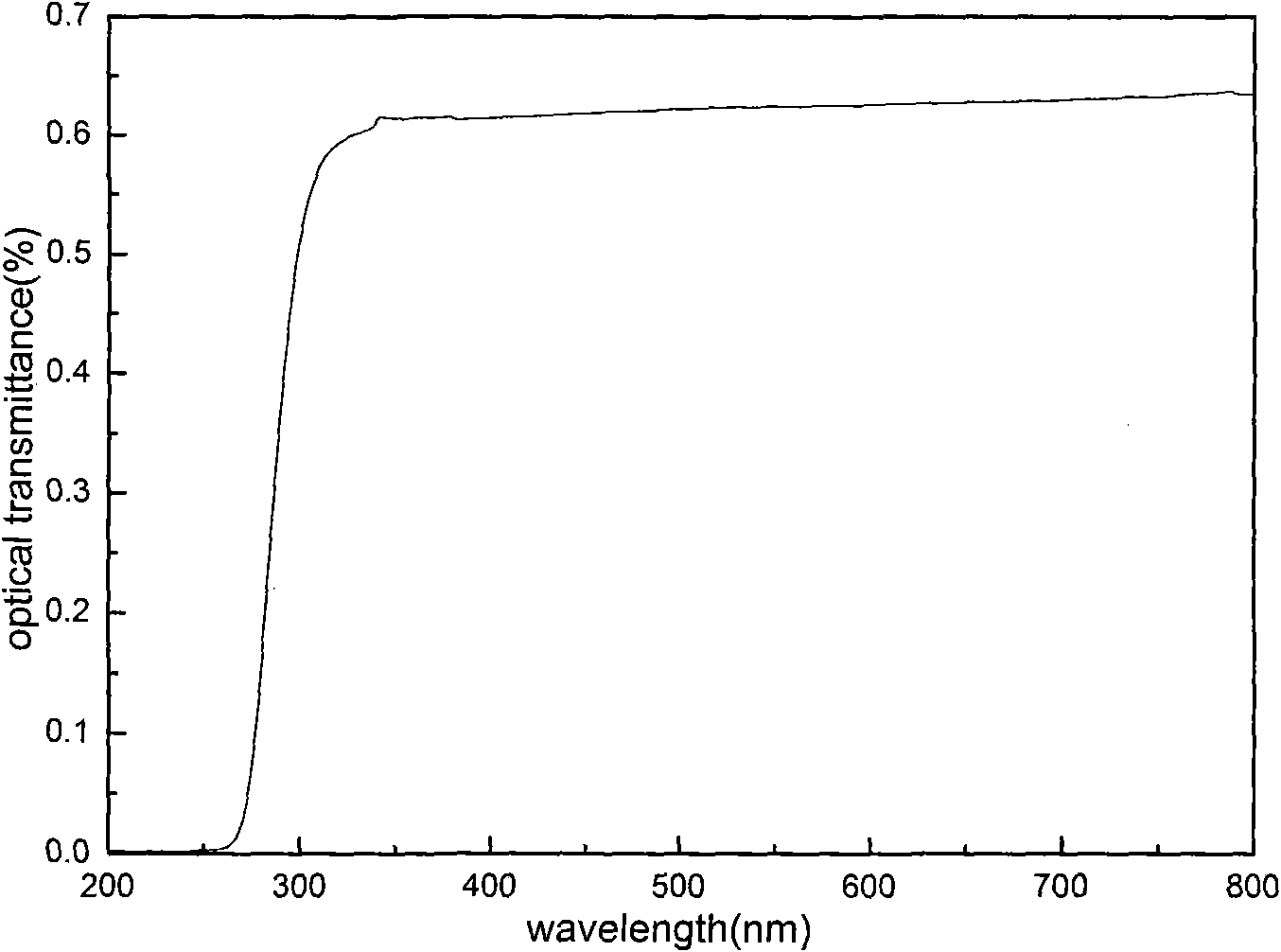

[0026] In this example, the solid-phase synthesis method was used to prepare yttrium hafnate powder. Pure hafnium oxide (HfO 2 ) and yttrium oxide (Y 2 o 3 ) according to the molar ratio of Hf and Y being 1:1, after mixing the materials, ball milling on a planetary ball mill at a speed of 250rpm for 6h. Dry the above mixture in a drying oven at 60°C, and then place it in a horse hearth furnace for heat treatment of the powder. The holding time is 2 hours; the particle size of the powder after ball milling and sieving is 120 mesh, and then dry pressing (5MP, 1min) and cold isostatic pressing (200MP, 3min), followed by vacuum sintering, annealing heat treatment and other processes to obtain pure phase yttrium hafnate (Y 2 f 2 o 7 ) transparent ceramics. The process conditions of powder heat treatment, sintering and annealing are shown in Table 1. The photo of the ceramic piece after polishing is as follows figure 1 Shown; X-ray diffraction pattern as figure 2 , indicat...

Embodiment 2

[0028] In this example, the solid-phase synthesis method was used to prepare yttrium hafnate powder. Pure hafnium oxide (HfO 2 ) and yttrium nitrate (Y(NO 3 ) 3 ) according to the molar ratio of Hf and Y being 1:1, after mixing the materials, ball milling on a planetary ball mill at a speed of 250rpm for 6h. Dry the above-mentioned mixture in a drying oven at 60°C, and then place it in a horse hearth furnace for heat treatment of the powder. , 1min) and cold isostatic pressing (200MP, 3min), and successively undergo vacuum sintering, annealing heat treatment and other processes to obtain pure phase yttrium hafnate (Y 2 f 2 o 7 ) transparent ceramics. The process conditions of powder heat treatment, sintering and annealing are shown in Table 1.

Embodiment 3

[0030] In this example, yttrium hafnate powder was prepared by co-precipitation method. Analytical pure hafnium chloride (HfCl 4 ) and yttrium nitrate (Y(NO 3 ) 3 ) is configured into a solution according to the molar ratio of Hf and Y as 1:1, and ammonium oxalate solution is used as a precipitating agent for precipitation reaction. After suction filtration and washing, the filter cake is placed in a vacuum drying oven to dry, and then placed in a horse The heat treatment of the powder was carried out in the furnace, and the holding time was 3 hours; after ball milling and sieving, dry pressing (5MP, 1min) and cold isostatic pressing (200MP, 3min) were performed, followed by vacuum sintering, annealing heat treatment and other processes to obtain pure Phase Yttrium Hafnate (Y 2 f 2 o 7 ) transparent ceramics. The process conditions of powder heat treatment, sintering and annealing are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com