Phaffia rhodozyma YZUXHONG686 and application thereof

A technology of YZUXHONG686CCTCCNO.M208262 and Phaffia yeast, applied in the field of Phaffia yeast strains, can solve the problems of low astaxanthin content, no large-scale production, and multiple energy sources, and achieve the effect of simple nutritional requirements and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

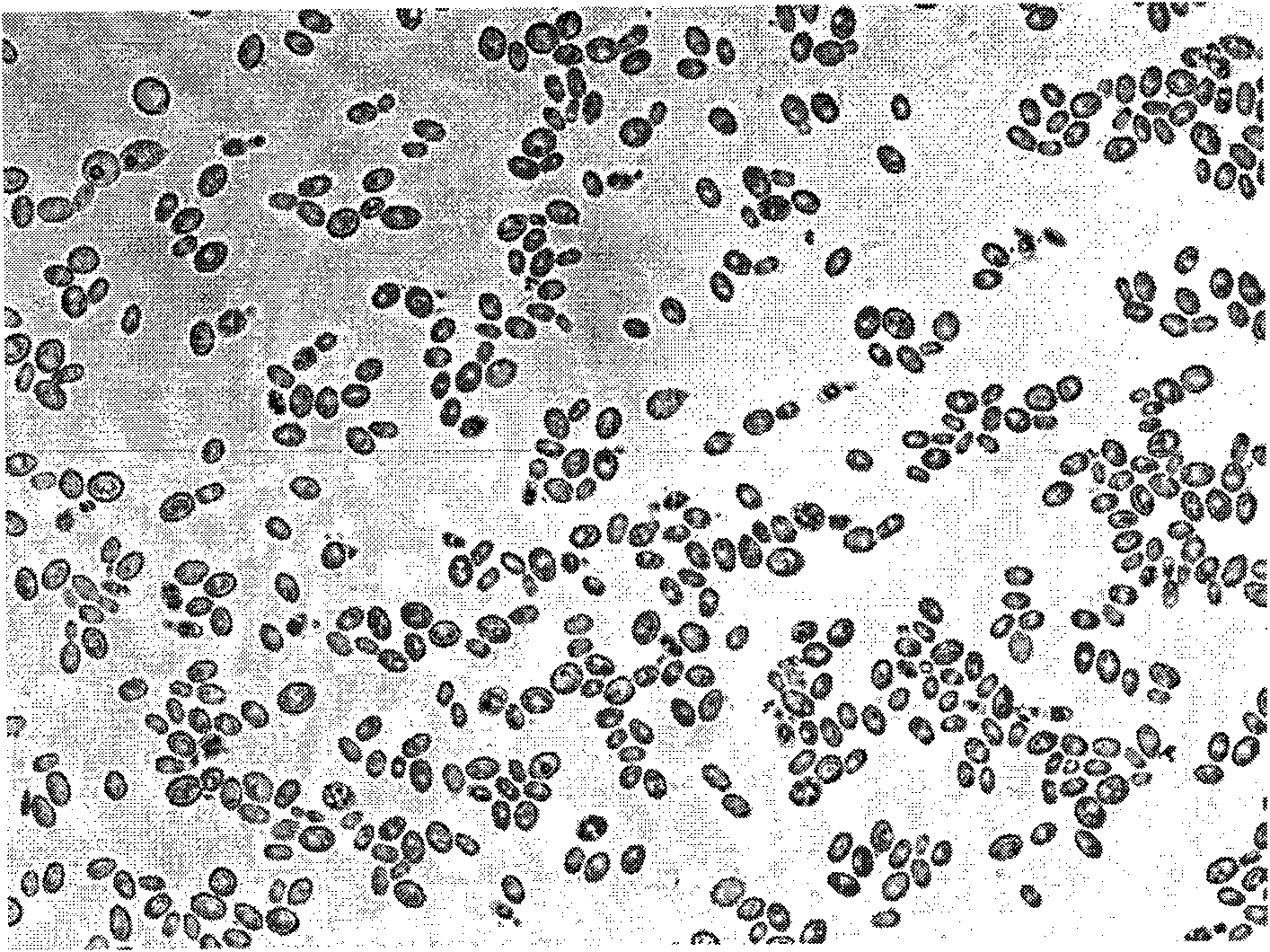

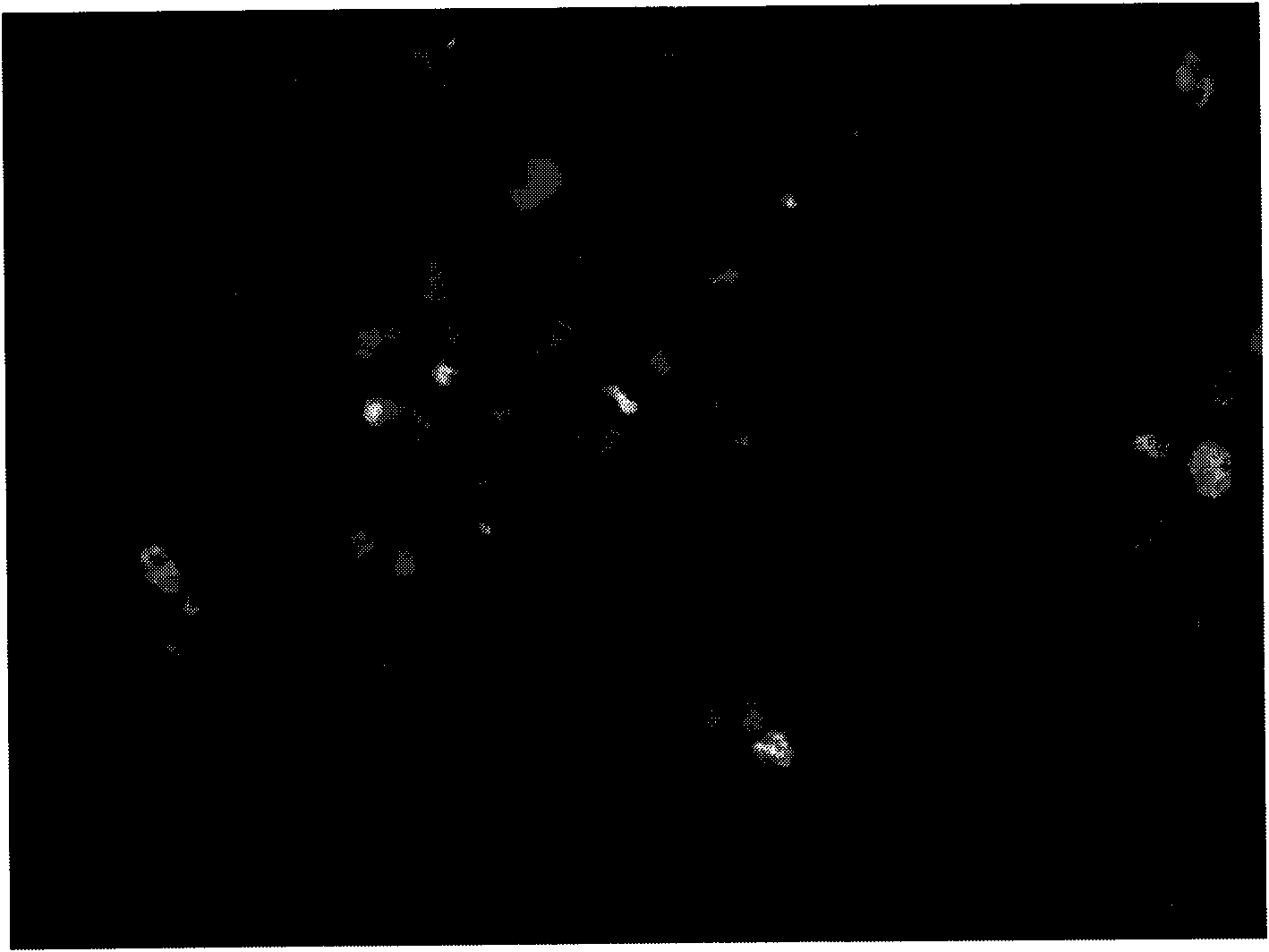

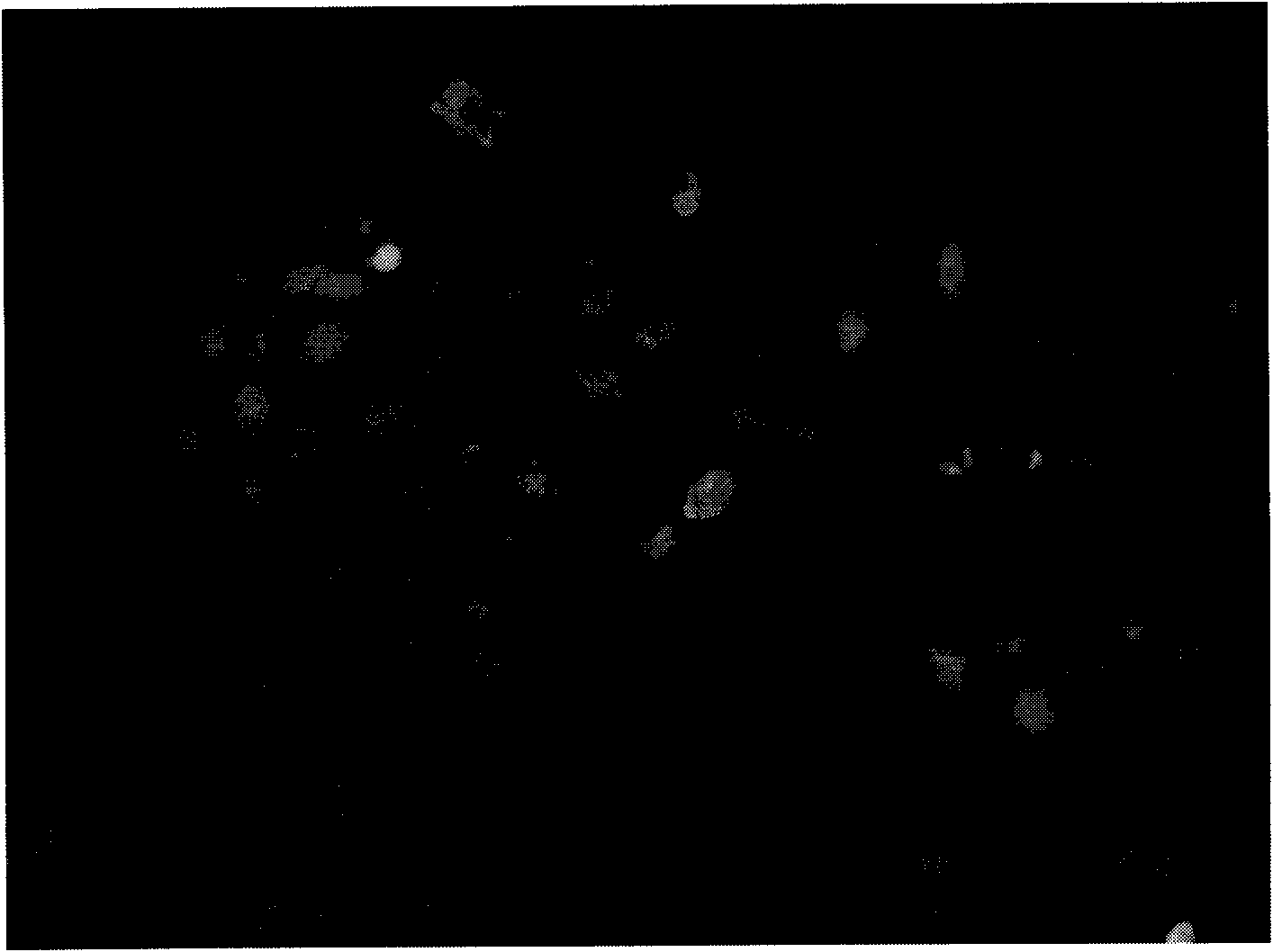

[0030] Example 1 Screening of strains with stable and high-yielding astaxanthin genetic traits

[0031] 1. Physical mutagenesis

[0032] (1) Take the fresh bacteria that have been activated for 36-40 hours (the starting strain is Phaffia rhodozyma 2.1557, purchased from the Culture Collection Center of the Institute of Microbiology, Chinese Academy of Sciences) and shake it in a sterilized Erlenmeyer flask equipped with glass beads for 3 minutes. Clear, centrifuge and wash with normal saline to suspend, take 6mL of normal saline bacterial suspension (10 7 1 / mL) in a sterile petri dish, placed on a magnetic stirrer, placed at 20cm under a 30W ultraviolet lamp, after the ultraviolet lamp was preheated for 30 minutes, open the dish cover and magnetic stirrer, and after irradiating for 3 minutes, centrifuge to discard the normal saline. The culture solution was cultivated overnight, the bacterial solution was taken and centrifuged, suspended in normal saline, diluted appropriatel...

Embodiment 2

[0042] Example 2 Determination of Carotenoid and Astaxanthin Contents in Phaffia Yeast

[0043] 1. Cultivation of Phaffia yeast

[0044] (1) Inoculate one loop of the slant of Phaffia yeast YZUXHONG686 into a 250 mL Erlenmeyer flask containing 30 mL of culture solution, and incubate at 23° C. and 170 rpm for 48 hours.

[0045] (2) Inoculate 10% of the inoculum into a Erlenmeyer flask filled with 30 mL of culture solution, and incubate at 23° C. and 170 rpm for 192 hours.

[0046] 2. Determination of Carotenoid Content

[0047] Determination of dry cell weight: absorb 4 mL of fermentation broth, centrifuge at 5000 rpm for 5 min, wash once with an equal amount of distilled water, and dry at 80°C until constant weight.

[0048] Take 4 mL of the above fermentation broth and add 4 mL of dimethyl sulfoxide (DMSO) at 56 °C, shake for 10 min, add 4 mL of acetone for shaking for 2 min, add 4 mL of 20% NaCl solution and 8 mL of petroleum ether for shaking for 1 min, then centrifuge at...

Embodiment 3

[0055] Example 3 Effects of different carbon sources on the yield of astaxanthin from Phaffia yeast YZUXHONG686

[0056] In sugar-free basal medium ((NH 4 ) 2 SO 4 3g / L, MgSO 4 ·7H 2 O 1.5g / L, KH 2 PO 4 1.5g / L, yeast extract 1.5g / L, corn steep liquor 10g / L) were added the following carbon sources (g / L) based on the principle of equal carbon moles: glucose 35, sucrose 33.3, maltose 35, D-fructose 35, mannitol 35.4, sorbitol 35.4, D-arabinose 35, absolute ethanol 26.9, glycerol 35.9, cultured at 23°C and 170rpm for 8 days, and measured the content of carotenoids. The results showed that the content of carotenoids in each medium: sucrose was 48mg / L, glucose and fructose are both 45mg / L, from the perspective of industrial production cost, choose sucrose or glucose as the best carbon source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com