Method for preparing direct vat set Lactobacillus casei subsp. rhamnosus freeze-dried powder

A Lactobacillus casei, direct-injection technology is applied in the field of preparation of lactic acid bacteria freeze-dried powder, and can solve the problems of lack of clear packaging method of freeze-dried powder, unsuitable pre-freezing conditions and packaging conditions, inability to achieve high-density culture, and the like, achieve the effect of promoting mass growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

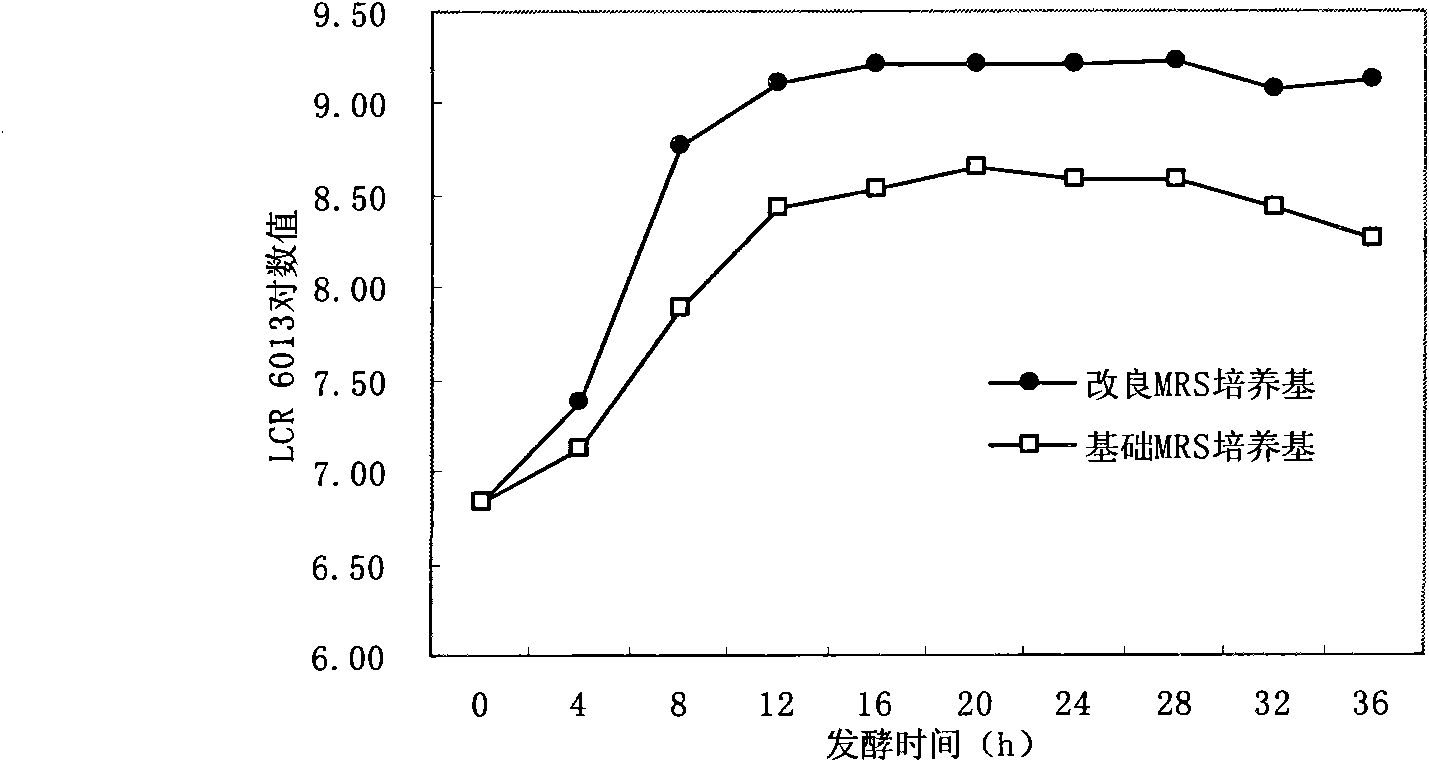

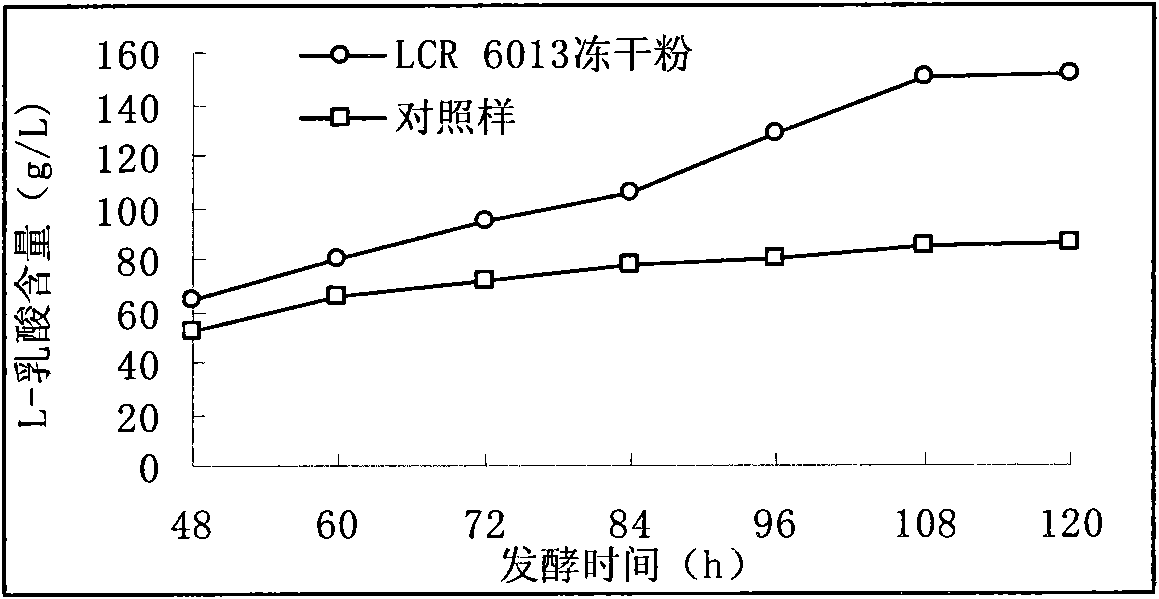

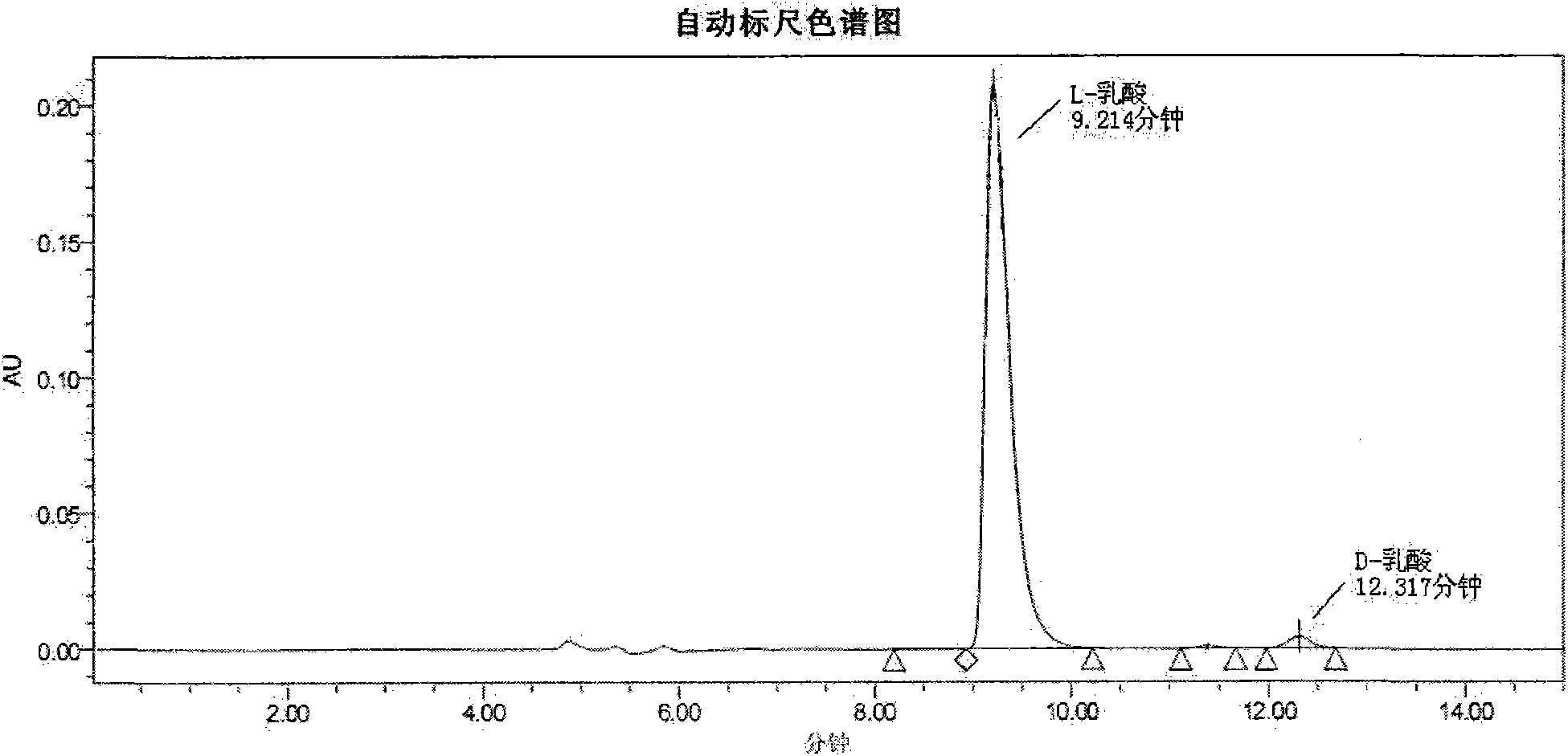

[0041] In the first step, Lactobacillus casei subsp. rhamnosus (No. CICC 6013, Lactobacillus casei subsp. rhamnosus 6013, preserved by China Industrial Microorganism Culture Collection Management Center, address: No. 32 Xiaoyun Road, Chaoyang District, Beijing, postcode: 100027) The freeze-dried powder of the above-mentioned lyophilized powder was placed in MRS medium, and cultured statically at 30°C for 24 hours to make a mother starter; the preparation of MRS medium: peptone 10g, yeast extract 5.0g, glucose 20.0g, diammonium citrate 2.0g , magnesium sulfate 0.58g, beef extract 10.0g, dipotassium hydrogen phosphate 2.0g, manganese sulfate 0.25g, sodium acetate 5.0g, Tween 801mL, distilled water 944.0g, sterilize at 0.08MPa for 20min, cool to 30℃ for later use.

[0042] The second step is to insert the mother starter into the working starter culture medium at a volume ratio of 3:100, and culture it statically at 30° C. for 24 hours to make a working starter. Preparation of wor...

Embodiment 2

[0052] In the first step, Lactobacillus casei subsp. rhamnosus (No. CICC 6013, Lactobacillus casei subsp. rhamnosus 6013, preserved by China Industrial Microorganism Culture Collection Management Center, address: No. 32 Xiaoyun Road, Chaoyang District, Beijing, postcode: 100027) The freeze-dried powder of the above-mentioned lyophilized powder was placed in MRS medium, and cultured statically at 28°C for 36 hours to make a mother starter; the preparation of MRS medium: peptone 8.0g, yeast extract 7.0g, glucose 15.0g, diammonium citrate 1.0 g, magnesium sulfate 0.48g, beef extract 5.0g, dipotassium hydrogen phosphate 1.0g, manganese sulfate 0.15g, sodium acetate 4.0g, Tween 803mL, distilled water 960g, sterilize at 0.10MPa for 15min, cool to 28℃ for later use.

[0053] In the second step, the mother starter is inserted into the working starter culture medium at a volume ratio of 5:100, and cultured statically at 28° C. for 36 hours to make a working starter. Preparation of work...

Embodiment 3

[0062] In the first step, Lactobacillus casei subsp. rhamnosus (No. CICC 6013, Lactobacillus casei subsp. rhamnosus 6013, preserved by China Industrial Microorganism Culture Collection Management Center, address: No. 32 Xiaoyun Road, Chaoyang District, Beijing, postcode: 100027) The freeze-dried powder of the lyophilized powder was placed in the MRS medium and cultured statically at 29°C for 30 hours to make a mother starter; the preparation of the MRS medium: peptone 9.0g, yeast extract 6.0g, glucose 17.5g, diammonium citrate 1.5 g, magnesium sulfate 0.53g, beef extract 7.5g, dipotassium hydrogen phosphate 1.5g, manganese sulfate 0.20g, sodium acetate 4.5g, Tween 802mL, distilled water 950.0g, sterilize at 0.09MPa for 18min, cool to 29℃ for later use.

[0063] In the second step, the mother starter is inserted into the working starter culture medium at a volume ratio of 2:100, and cultured statically at 29°C for 30 hours to make a working starter. Preparation of working cultu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com